Asphalt tank performing heating through waste heat tail gas

An exhaust gas heating and asphalt tank technology, applied in the field of asphalt tanks, can solve the problems of easy sealing, low production efficiency and poor safety of pressure vessels, saving equipment costs and operating costs, high production efficiency and increased internal space. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

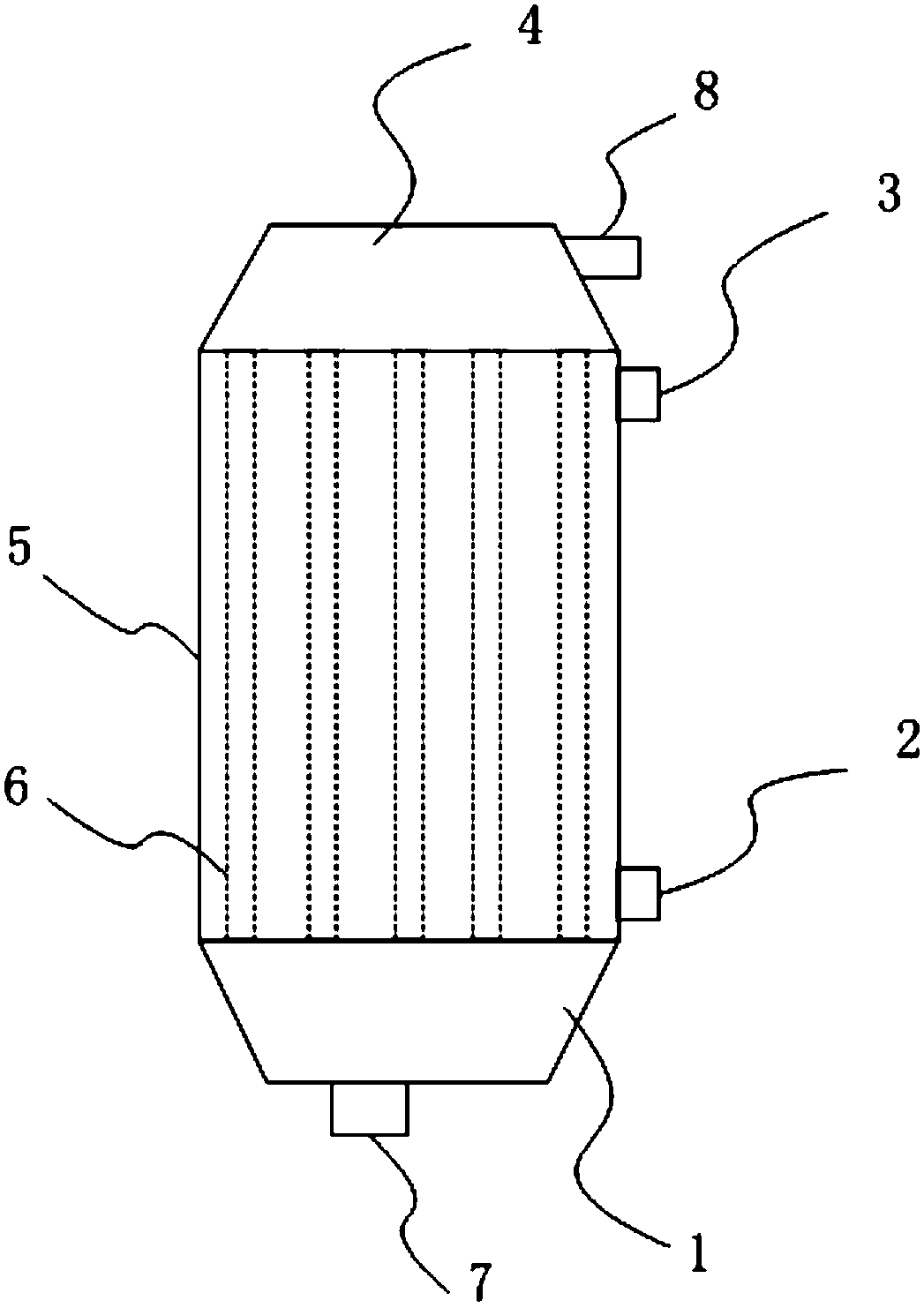

[0013] An asphalt tank heated by waste heat exhaust gas, comprising a tank body, the tank body comprising an upper buffer bin 4, a lower buffer bin 1 and an asphalt heating bin 5 arranged between the upper buffer bin and the lower buffer bin, the asphalt The heating chamber is provided with an asphalt inlet 3 and an asphalt outlet 2, the bottom of the lower buffer chamber is provided with a waste heat tail gas inlet 7, and a plurality of waste heat tail gas tubes 6 are uniformly arranged along the inner wall of the asphalt heating chamber. The waste heat tail gas tubes are respectively connected with the upper buffer bin and the lower buffer bin, and the upper buffer bin is provided with a waste heat tail gas outlet 8 .

[0014] Further, an insulation layer (not shown) is provided on the outside of the tank.

[0015] The tail gas of calcined petroleum coke in the production workshop of carbon products enterprises is generally discharged directly into the atmosphere after purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com