Water cooling tower with demister

A water cooling tower and mist eliminator technology, applied in the direction of water shower coolers, heat exchanger types, chemical instruments and methods, etc., can solve the problems of surrounding environmental pollution, waste of water resources, high cost, etc., to avoid serious waste, Effect of reducing pollution and simple structure

Inactive Publication Date: 2018-10-23

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The working principle of the cooling tower is to use the wind blowing in from the lower part of the cooling tower to form convection with the water sprayed from top to bottom. Part of the water evaporates in the convection and takes away the corresponding latent heat of evaporation, thereby reducing the temperature of the water and convection. The heated gas is discharged into the atmosphere under the action of the fan on the top of the cooling tower, and the cooled liquid is recycled, but the disadvantage is that in the process of convective contact heat exchange, a large amount of water is evaporated and consumed, and smaller liquid droplets Entrained by the airflow, causing serious waste of water resources and pollution of the surrounding environment

However, since the pressure drop of the conventional cyclone separator is often as high as 1000Pa~1500Pa, the gas must be pressurized to realize the gas-liquid separation of the cyclone separator, which is complicated and uneconomical

[0004] CN203396259U discloses a water-saving cooling tower, in which nozzles and exhaust fans are installed, the nozzles are connected to bypass valves and air coolers through pipelines, the other end of the air coolers is connected to circulating water pumps, and the other end of circulating water pumps is connected to circulating pools through pipelines , the other end of the bypass valve is connected to the circulating water pool through the pipeline, and the temperature of the hot circulating water entering the cooling tower can be reduced by setting the air cooler, thereby reducing the evaporation loss, but the system is more complicated and the cost is higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0047] After the cooling water tower with demister of the present invention is used, the white smoke at the gas outlet is obviously eliminated, and the apparent water concentration at the gas outlet is lower than 0.5g / Nm 3 , while the apparent water concentration at the gas outlet of an ordinary cooling tower is 10-15g / Nm 3 , Demist efficiency ≥ 95%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

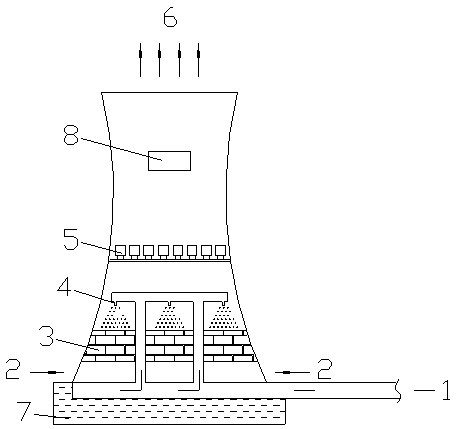

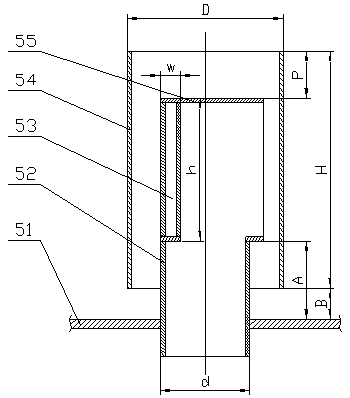

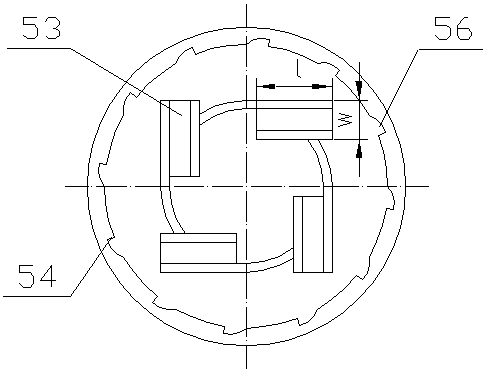

The invention discloses a water cooling tower with a demister. The water cooling tower comprises a water cooling pond, heat-dissipating filler, a water distribution system, the demister and a fan sequentially from top to bottom. A wind inlet is formed above the water cooling pond. The water distribution system is connected with a hot water pipeline. A gas outlet is formed in the top of the water cooling tower. The demister is composed of a tower plate and a plurality of demisting assemblies. Each demisting assembly comprises a gas raising pipe and an outer cylinder. The outer cylinder is arranged on the outer side of the gas raising pipe. The outer cylinder and the gas raising pipe are located on the same axis. The gas raising pipe is fixed to a tower disc. A sealing cover plate is arranged on the top of the gas raising pipe. A rectification channel is formed in the periphery of the gas raising pipe. According to the water cooling tower, the demister gathers a large quantity of liquidstate mist drops carried away by airflow in the convection contact heat exchange process, severe waste of water resources is avoided, pollution to surrounding environment is reduced, the structure issimple, the pressure drop is small, installing is convenient, and recovery treatment of exhausted water mist of the water cooling tower can be achieved effectively.

Description

technical field [0001] The invention relates to a cooling tower with a demister, which belongs to the technical field of energy saving and environmental protection. Background technique [0002] Cooling towers are buildings used to cool water, and are generally widely used in factories such as power plants, chemical plants, and cement plants that require a large amount of water temperature control. The working principle of the cooling tower is to use the wind blowing in from the lower part of the cooling tower to form convection with the water sprayed from top to bottom. Part of the water evaporates in the convection and takes away the corresponding latent heat of evaporation, thereby reducing the temperature of the water and convection. The heated gas is discharged into the atmosphere under the action of the fan on the top of the cooling tower, and the cooled liquid is recycled, but the disadvantage is that in the process of convective contact heat exchange, a large amount ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28C1/00B01D45/08F28F25/04F28F25/00

CPCF28C1/00B01D45/08F28F25/00F28F25/04

Inventor 方向晨王海波王晶李欣刘平金平李磊韩天竹

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com