Copper adsorbent for acetylene converter guard bed

A sorbent and acetylenic technology, applied in the field of acetylenic converters, can solve the problems of low efficiency of environmental impact pollutants and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] While the following is described in connection with specific embodiments, it should be understood that this description is intended to illustrate, and not to limit, the scope of the foregoing description and appended claims.

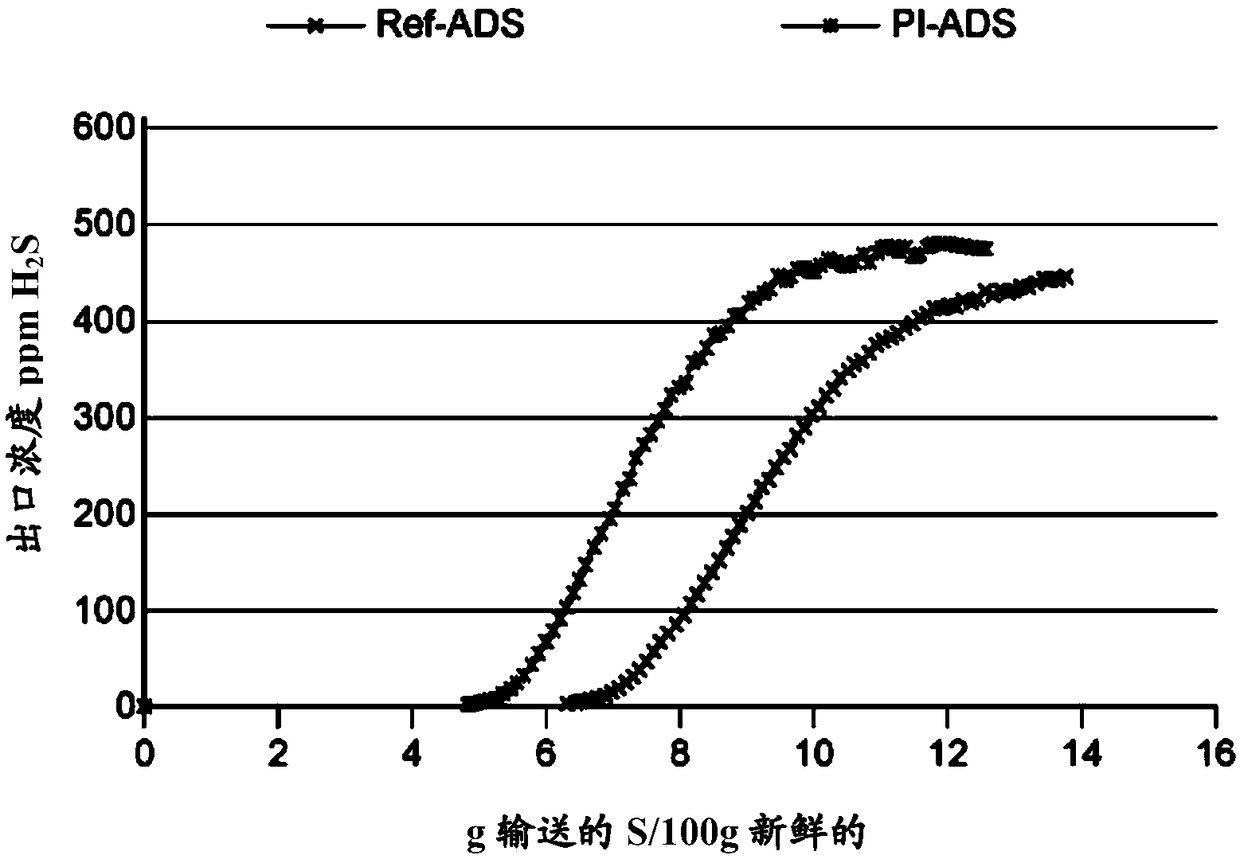

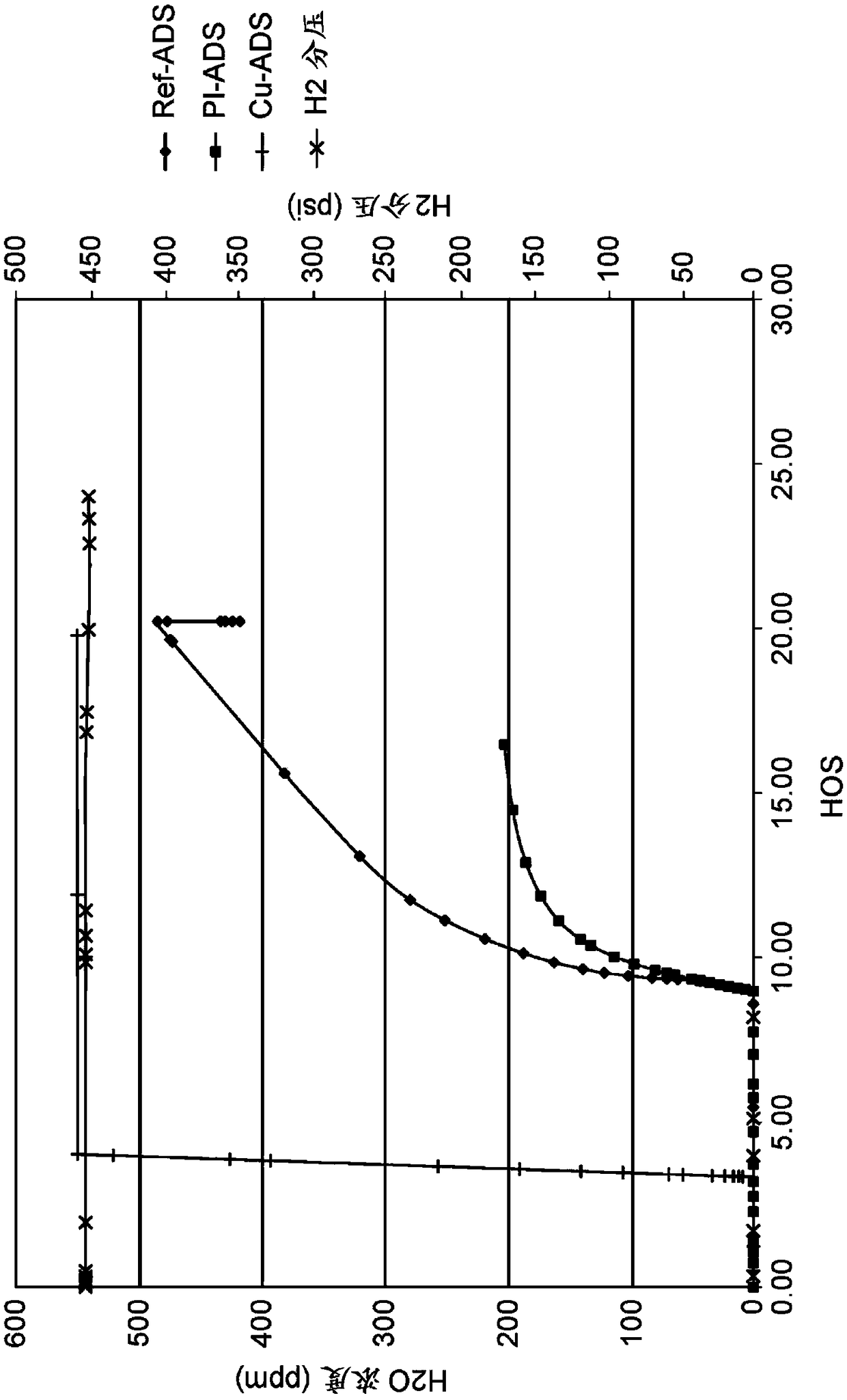

[0060]A first embodiment of the invention is a process for removing pollutants from a stream comprising contacting an olefin-containing olefin stream with a sorbent in a pollutant removal zone, wherein the sorbent comprises copper, copper oxide, cuprous oxide and halides; selectively removing one or more contaminants selected from the group consisting of mercury, arsenic, phosphine, and sulfur compounds from an olefin stream; and selectively converting the olefin stream to The acetylenic compound is converted to an olefin, wherein the acetylenic conversion zone receives hydrogen. An embodiment of the invention is one, any or all of the previous embodiments in this paragraph up through the first embodiment in this paragraph, wherein the sorbent fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com