Transparent conductive film, method for manufacturing transparent conductive film, metal mold, and method for manufacturing metal mold

A technology of transparent conductive film and metal mold, which is applied to equipment for manufacturing conductive/semiconductive layers, manufacturing of cables/conductors, conductive layers on insulating carriers, etc., and can solve problems such as supply anxiety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

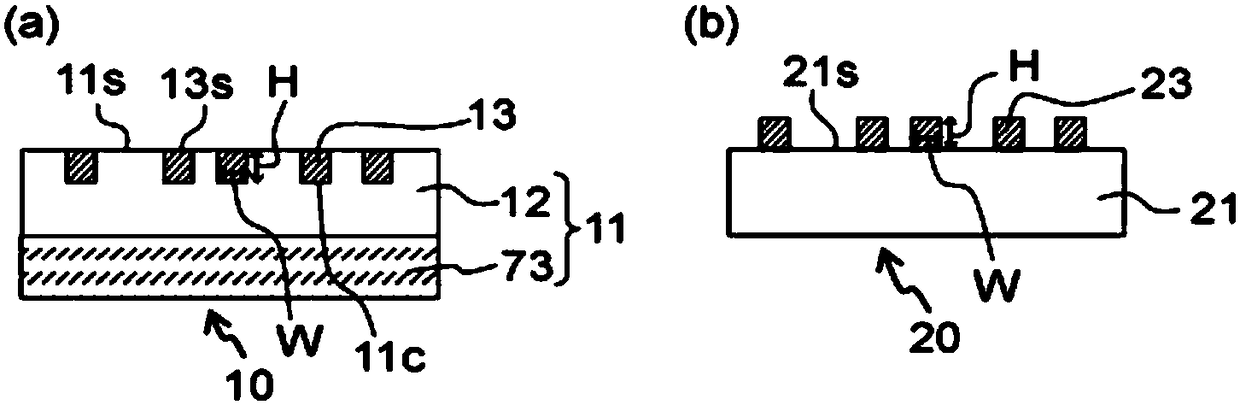

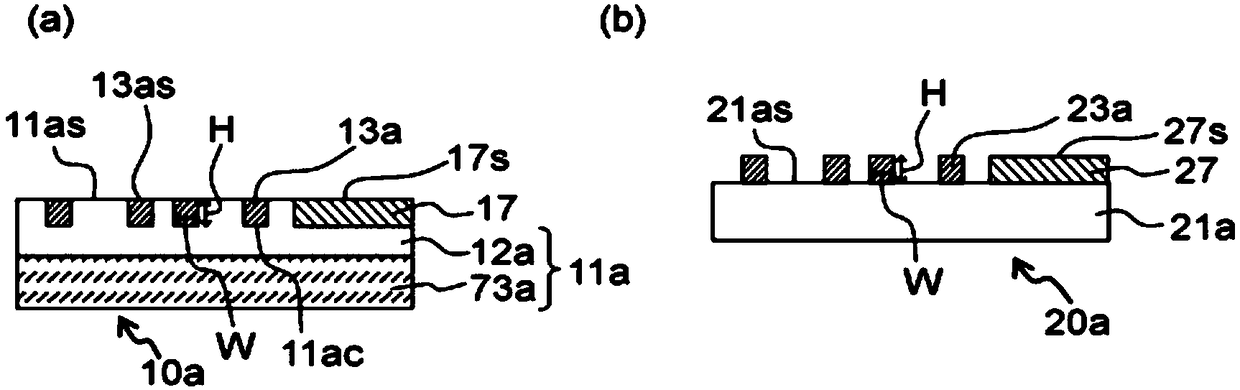

Embodiment 1

[0165] Polyphenylene was mixed in a solvent of DMF (N',N'-dimethylformamide) (manufactured by Wako Pure Chemical Industries) and THF (tetrahydrofuran) (manufactured by Tokyo Chemical Industry) at a volume ratio of 1:1. Ethylene (weight average molecular weight: 23 million) (manufactured by Polysciences) was dissolved to prepare a polystyrene solution having a concentration of 0.1 wt%. Using this polystyrene solution as a raw material (spinning liquid), on a Si wafer with a thermally oxidized film with a thickness of 50 nm, use an electrospinning device (manufactured by Fuence Co., Ltd., ES-2000S2) with a distance of 15 cm between electrodes. , a potential difference of 15 kV, and a liquid delivery rate of 30 μL / min, the polystyrene nanofibers were deposited (spread) for 10 seconds. The average fiber diameter of the obtained fibers was 1000 nm. Next, the Si wafer with the nanofiber thermal oxide film deposited thereon was heat-treated at 130° C. for 30 minutes to prepare a Si ...

Embodiment 2

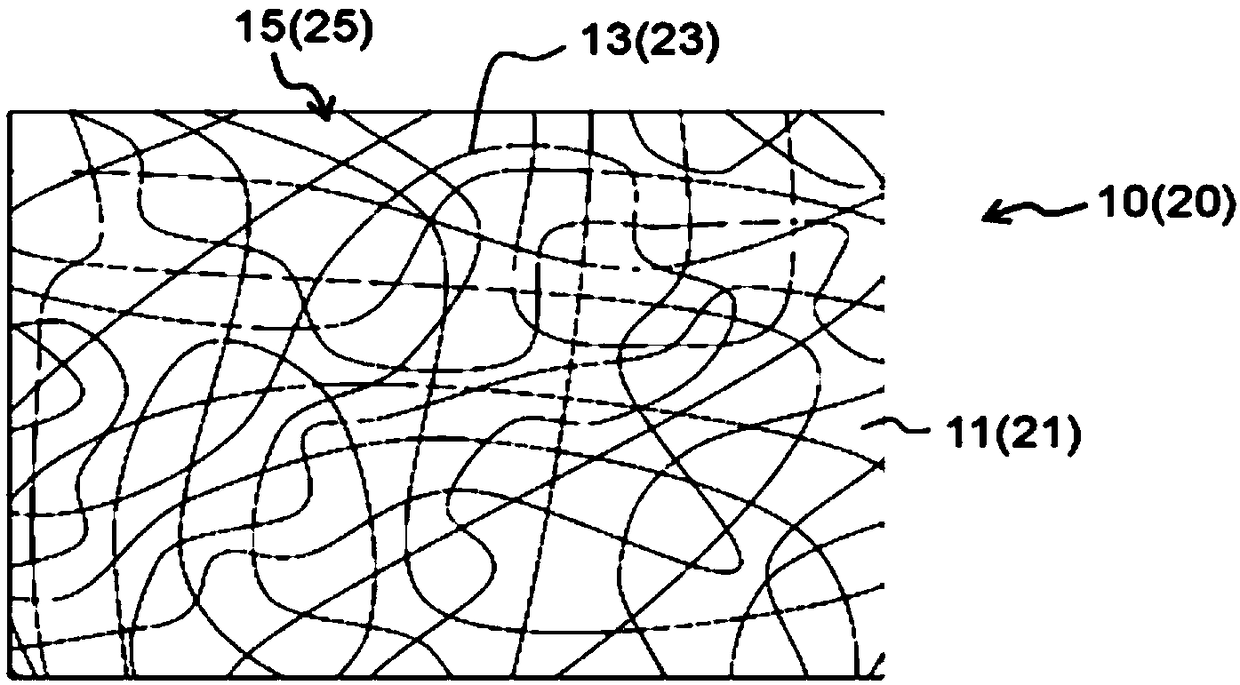

[0173] A polystyrene solution with a concentration of 0.05 wt% was used as the spinning solution, the spreading time of the nanofibers was set to 16 seconds, and the etching time of the Si wafer was set to 16 seconds. Make the Si basic mold by way. The average fiber diameter of the nanofibers was 500 nm, and the area ratio (coverage ratio) of the nanofibers adhering to the thermal oxide film-attached Si wafer was 6.8%. Also, the protrusions of the concavo-convex pattern of the Si base mold had a linear shape with a width and a height of 500 nm, and formed a random network structure in plan view.

[0174] Using the obtained Si base mold having a random network structure, a transparent conductive film was produced under the same conditions as in Example 1. A cross-sectional SEM photograph of the produced transparent conductive film is shown in Figure 11B . The height of the conductive portion was 300 nm, the width was 500 nm, and the ratio thereof was 0.6. The sheet resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com