Cereal cleaning, screening and impurity-removing device

A grain cleaning and sieve plate technology, applied in the agricultural field, can solve problems affecting grain storage, high manual output, low efficiency, etc., and achieve the effects of improving health and safety, improving efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

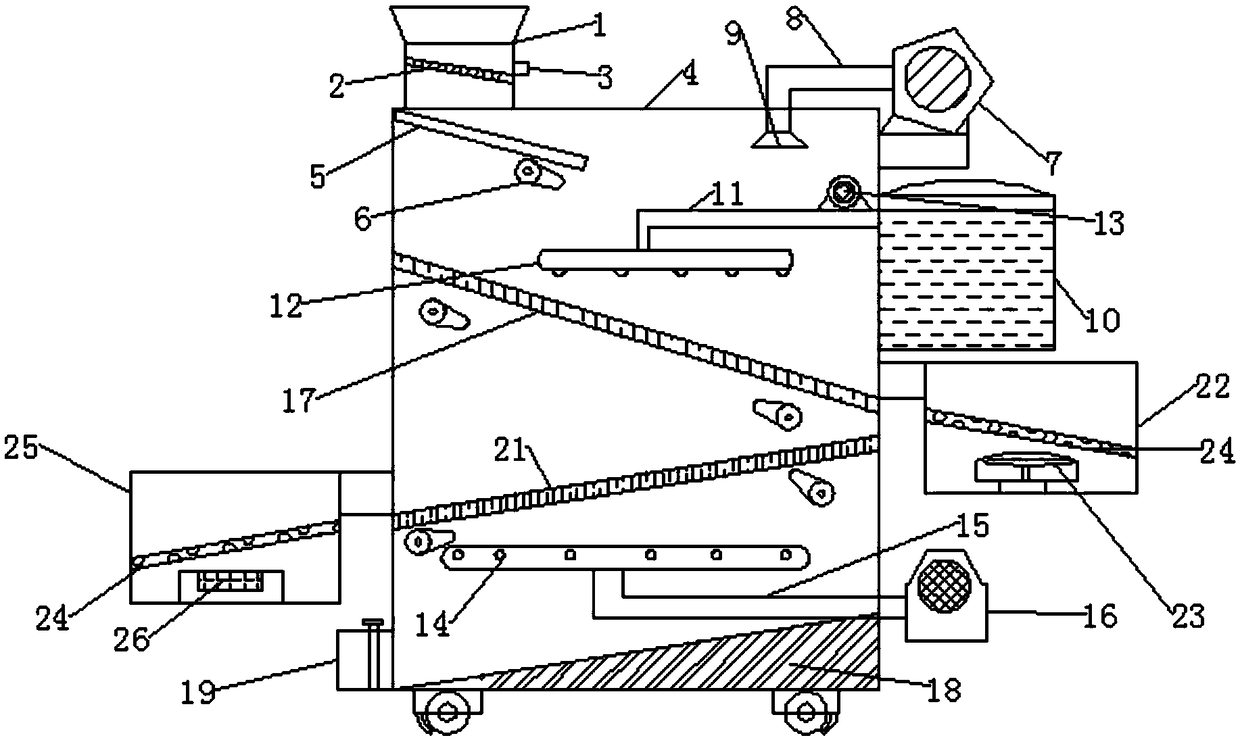

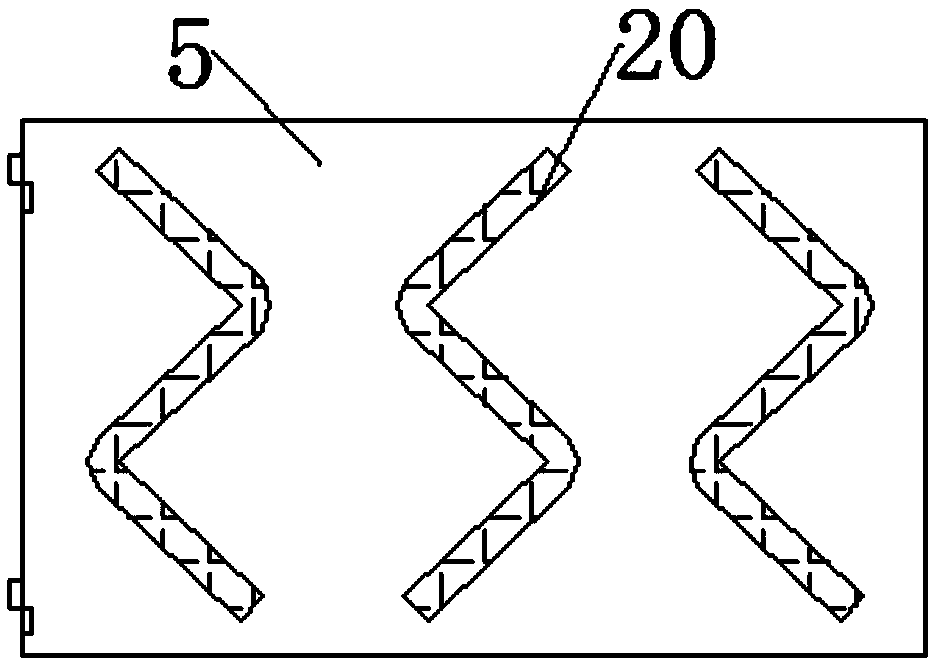

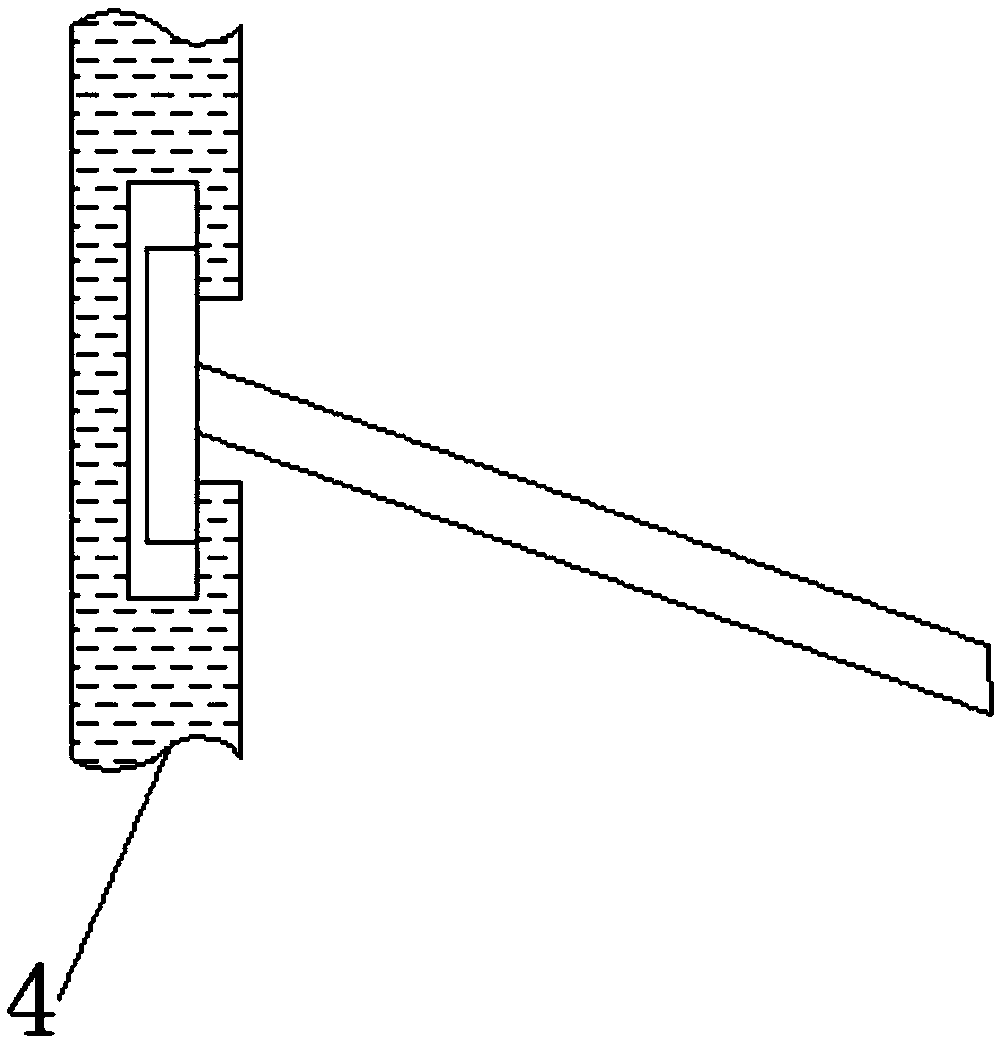

[0018] see Figure 1-3 , a grain cleaning and screening impurity removal device, comprising a feed pipe 1, a grid 2, a garbage discharge pipe 3, a screening box 4, a shaking plate 5, a vacuum cleaner 7, a water tank 10, a water spray pipe 11, a water spray plate 12, Suction pump 13, spray discharge 14, aeration device 16, sieve plate, inclined guide plate 18, sewage pipe 19, seed air-drying box 22 and secondary grain collection box 25, described screening box 4 tops are provided with feed pipe 1 , the inside of the feed pipe 1 is inclined with a grid 2, the lowest end of the grid 2 is equipped with a waste discharge pipe 3, the bottom of the screening box 4 is equipped with a guide wheel, and a hand brake is provided on the guide wheel, and the screening box 4 is equipped with a shaker. Plate 5, one end of the shaker plate 5 is internally hinged w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com