A kind of polyester shape memory material and preparation method thereof

A memory material and polyester technology, applied in the field of polyester shape memory material and its preparation, can solve the problems of poly(octanediol-citric acid) ester elastomer without memory, long polymerization period, etc., and achieve excellent thermal stability The effect of stability, short preparation period and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

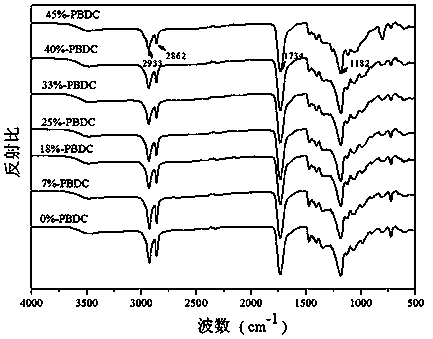

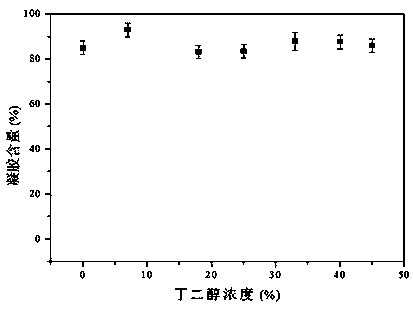

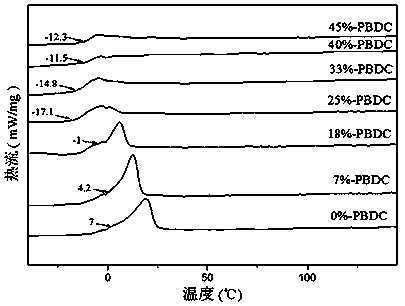

[0038] A polyester shape memory material, which is polymerized from diol and citric acid at a molar ratio of 3:2, and the diol is 1,10-decanediol.

[0039] The preparation method of above-mentioned material, comprises the following steps:

[0040] (1) Take 1,4-butanediol (0mol; 0g), 1,10-decanediol (0.0285mol; 5.00g) and citric acid (0.019mol; 4.00g) and mix them with nitrogen gas for 20 minutes; Melt at 165°C, stir and polymerize for 20 minutes, then lower the temperature to 140°C, and stir for 30 minutes to increase the viscosity of the reaction system to obtain a prepolymer;

[0041] (2) Drop-coat or spin-coat the prepolymer onto a glass slide, put it in a vacuum oven, and cross-link for 20 hours at 80°C; The ester shape memory material is designated as sample 1.

Embodiment 2

[0043] A polyester shape memory material, which is polymerized by diol and citric acid with a molar ratio of 3:2, the diol is a mixture of 1,10-decanediol and 1,4-butanediol, 1, The mole of 4-butanediol is 7% of the total mole of glycols.

[0044] Compared with Example 1, the preparation method of the above materials differs in that the amount of 1,4-butanediol added in step (1) is 0.002 mol, and the amount of 1,10-decanediol added is 0.0265 mol, to obtain butane The polyester shape memory material with a diol content of 7% is designated as sample 2.

Embodiment 3

[0046] A polyester shape memory material, compared with Example 2, the difference is that the mole of 1,4-butanediol is 18% of the total mole of diols.

[0047] Compared with Example 2, the preparation method of the above materials differs in that: in step (1), the amount of 4-butanediol added is 0.005 mol, and the amount of 1,10-decanediol added is 0.0235 mol, to obtain butanediol A polyester shape memory material with an alcohol content of 18% is designated as sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com