Pretreatment method of novel wet-process flower basket

A pretreatment and wet method technology, which is applied in the field of pretreatment of new wet flower baskets, can solve the problems that affect the economic benefits of production enterprises, the limited number of new wet flower baskets, and affect the production progress, so as to speed up the pretreatment speed and increase the quantity , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

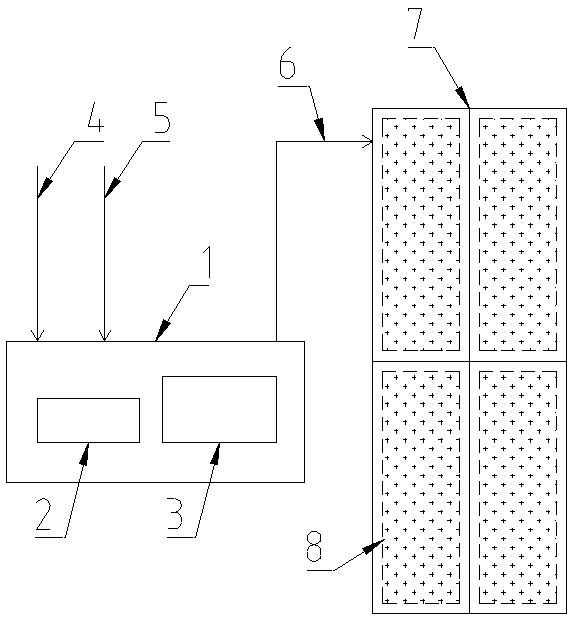

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that once the trough-type texturing machine leaves the factory, the structure has been fixed, and the number of its own lye tank and ozone hydrochloric acid tank has also been fixed. Only relying on the original lye tank to pretreat the new wet flower basket, each The number of new wet-process flower baskets pretreated by the trough-type texturing machine is limited each time. For the large number of wet-process flower baskets required for texturing, the production progress will be prolonged and the production efficiency will be affected. Moreover, the trough-type texturing machine is expensive and costs tens of millions. , repurchasing is an economic burden that general production enterprises cannot bear, so look for other new wet flower basket pretreatment methods suitable for the implementation of existing trough-type texturing machines, make full use of existing trough-type texturing machines, and improve existing troughs. It is a wise choice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com