Cooling device for liquid medicine production process

A technology for pharmaceutical production and cooling device, which is applied to heat exchange equipment, damage protection, fixed tubular conduit components, etc., can solve the problems of long time required for natural cooling, inability to control temperature for cooling, changes in medicinal properties, etc., and improve the cooling effect. , The cooling effect is good, the effect of avoiding damage or blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

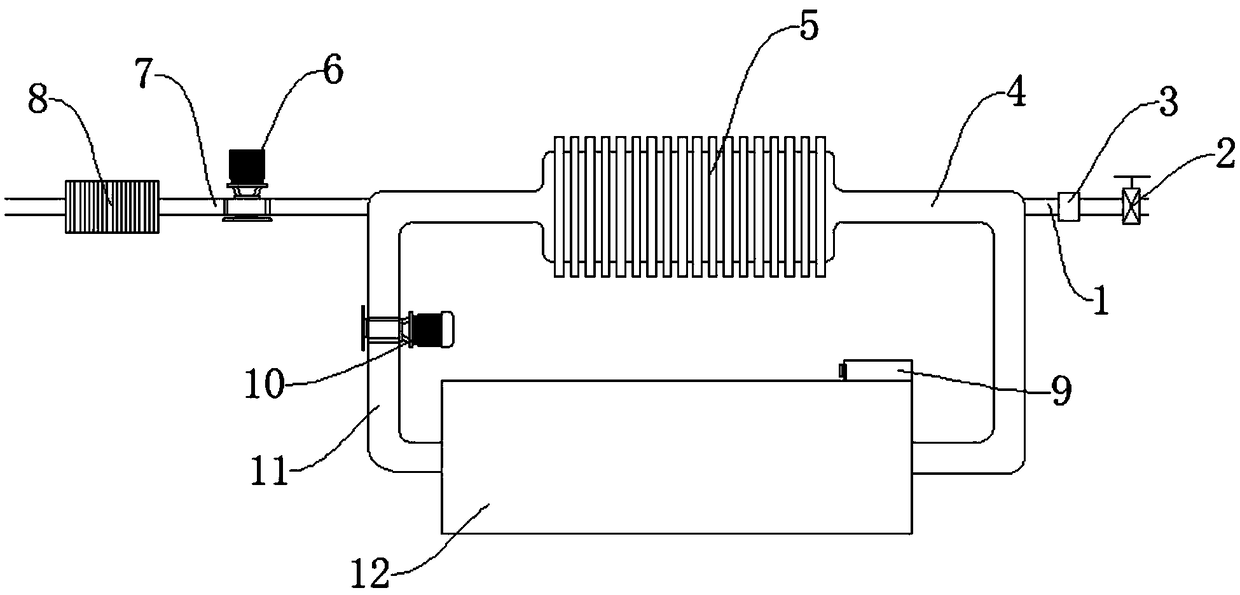

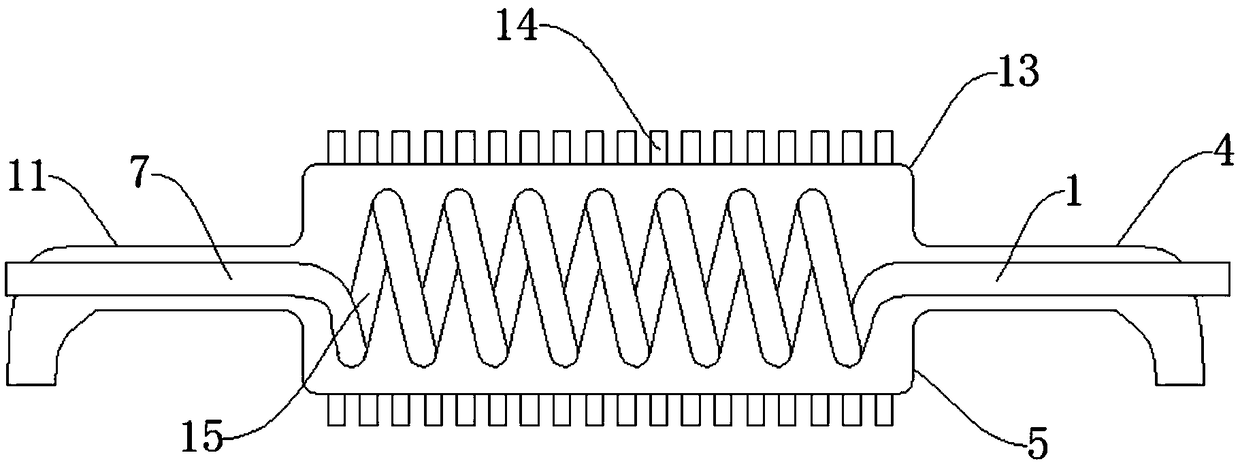

[0028] Such as Figure 1-Figure 4 As shown, a cooling device in the production process of liquid medicine includes a liquid medicine cooler 5, a cooling water cooler 12 and a controller 9, and the liquid medicine cooler 5 includes a liquid medicine cooling box 13 and is fixedly installed on the liquid medicine The medicinal liquid spiral tube 15 inside the cooling box 13, the outer wall of the medicinal liquid cooling box 13 is fixedly equipped with cooling water cooling fins 14, and the cooling water cooling fins 14 are used to cool the medicinal liquid in the medicinal liquid spiral tube 15 when the cooling water , for the cooling water to dissipate heat, the two ends of the liquid cooling box 13 are respectively connected to the outlet pipe 11 and the return pipe 4, the outlet pipe 11 is provided with the medicine inlet pipe 7 connected to the left end of the medicinal liquid spiral pipe 15, and the return pipe 4 is provided with The drug outlet pipe 1 connected to the righ...

Embodiment 2

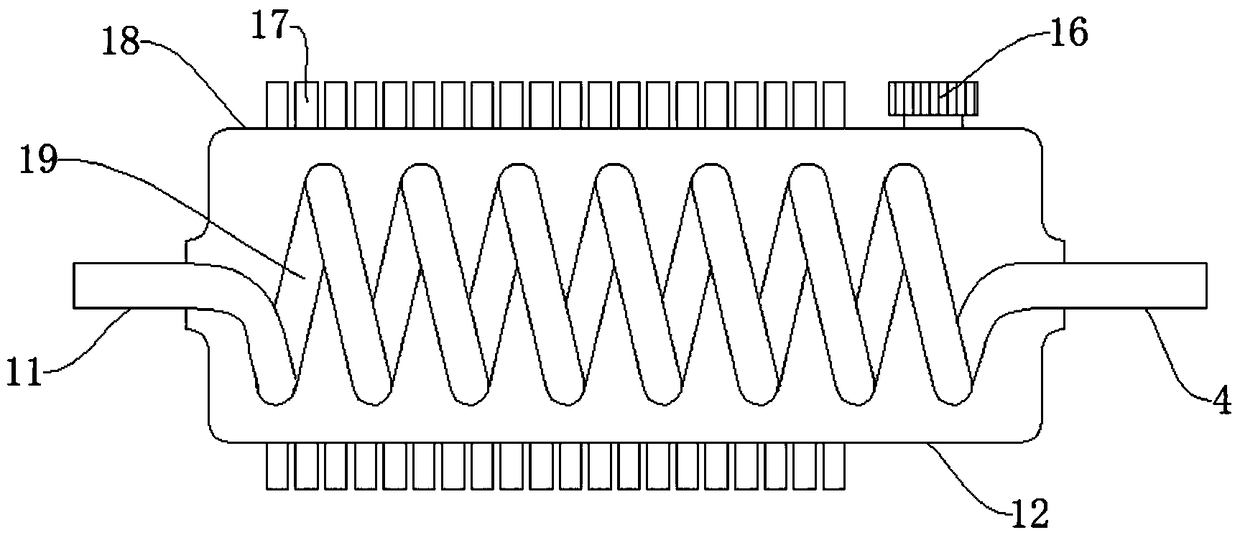

[0033] Such as Figure 5 As shown, on the basis of Embodiment 1, Embodiment 2 is provided with a cooling water tank 20 in the middle of the cooling water spiral pipe 19. One end of the cooling water tank 20 is connected to the cooling water spiral pipe 19 connected to the water outlet pipe 11, and the other end is connected to the cooling water spiral pipe 19. The cooling water spiral pipe 19 of the water pipe 4 is connected to each other, and the cooling water tank 20 is added in the cooling water cooler 12, which significantly improves the cooling water volume in the cooling water circulation system, prolongs the cooling water circulation period, and the cooling effect of the cooling water and the medicine liquid is improved. There is a huge boost.

[0034] The rest of the structure and working principle of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0036] Such as Image 6 As shown, Embodiment 3 is based on Embodiment 1. Nine deflectors 21 are arranged at equal intervals on the inner wall of the cooling water tank 20. There is a gap at one end of the deflector 21, and the direction of the gap of the adjacent deflector 21 is opposite. The deflector 21 added in the cooling water tank 20 further prolongs the circulation period of the cooling water, and further improves the cooling effect of the cooling water and the liquid medicine.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap