Multi-station sample sending and recycling device used for electrostatic suspension and using method thereof

A technology of electrostatic suspension and recovery device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0035] In the embodiment of the present invention: m=36,

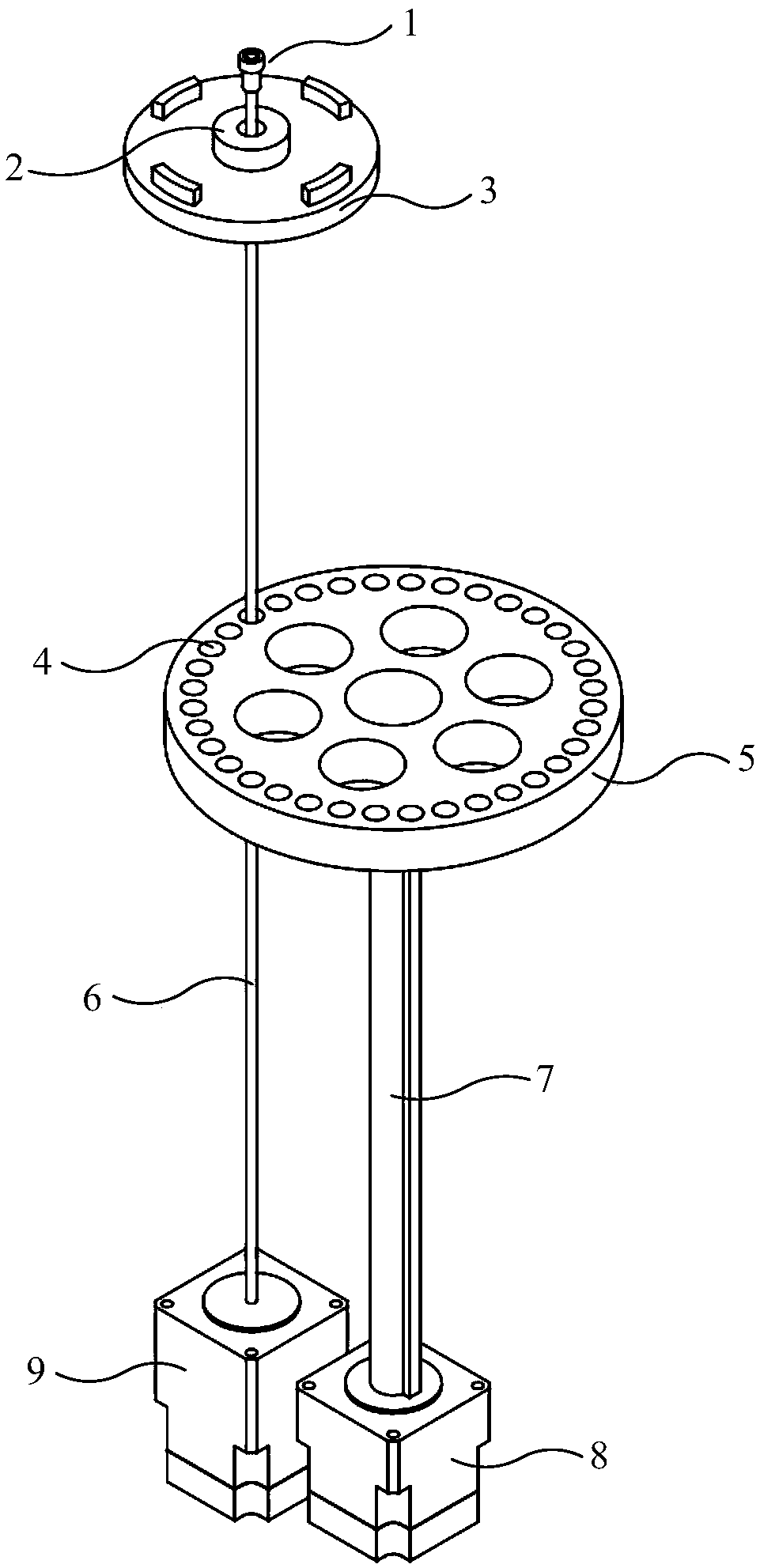

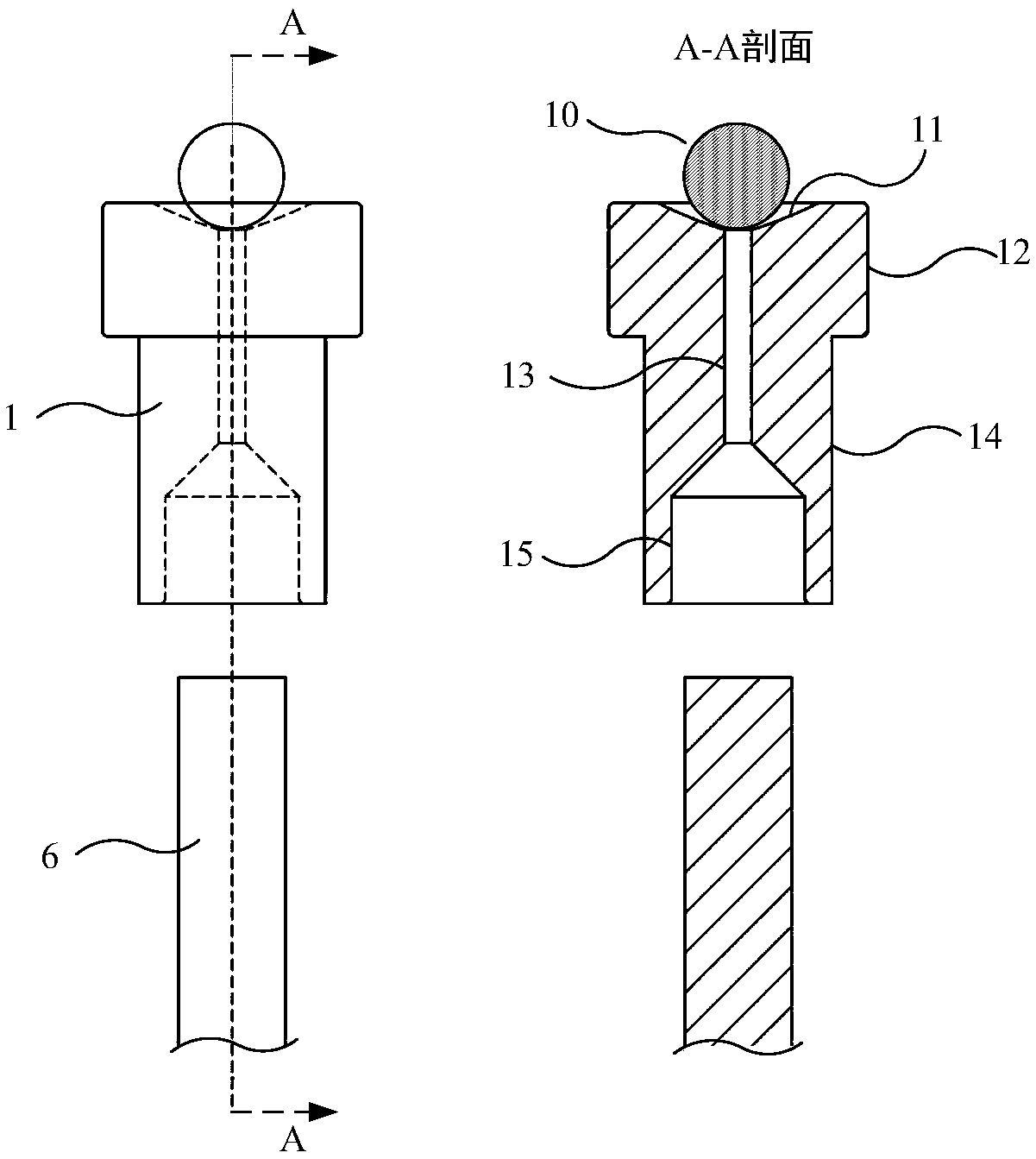

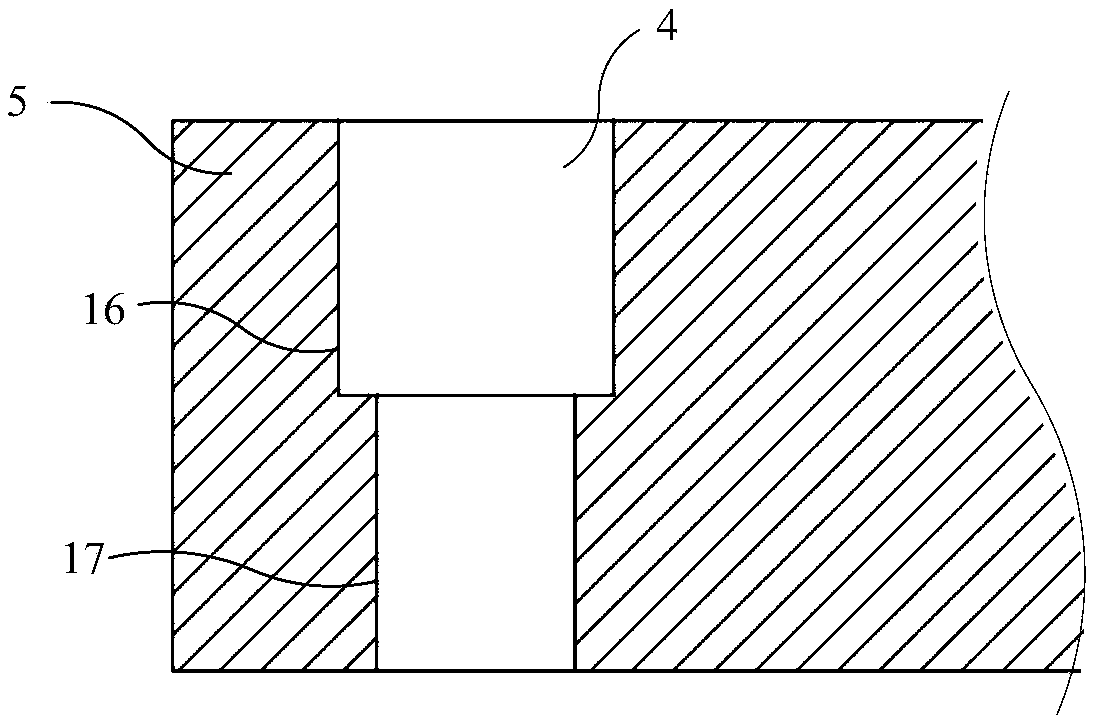

[0036] 36 sample cups 1, sample tray 5, transmission rod 6, metal rod 7, first stepping motor 8 and second stepping motor 9 of the multi-station sample delivery and recovery device for electrostatic suspension; the sample tray 5 passes through the metal The rod 7 is connected with the first stepper motor 8, so that the sample tray 5 realizes the rotational movement along the axis; the transfer rod 6 is connected with the second stepper motor 9, so that the transfer rod 6 moves vertically; the sample tray There are 36 sample stations with stepped through-holes on the circumference of 5, and 36 sample cups 1 are placed on the sample stations. There is a concave slope structure, the center of the slope is provided with a through hole, the through hole extends to the lower end and connects the round hole 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com