Blade grinding device of tobacco cutter

The technology of a sharpening device and a shredder is applied to the grinding drive device, the grinding/polishing safety device, the grinding frame, etc., which can solve the problem of difficult maintenance, complex structure of the sharpening device, and high consumption of grinding wheels. and other problems, to achieve the effect of high effective utilization rate of equipment, good social and economic benefits and application prospects, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

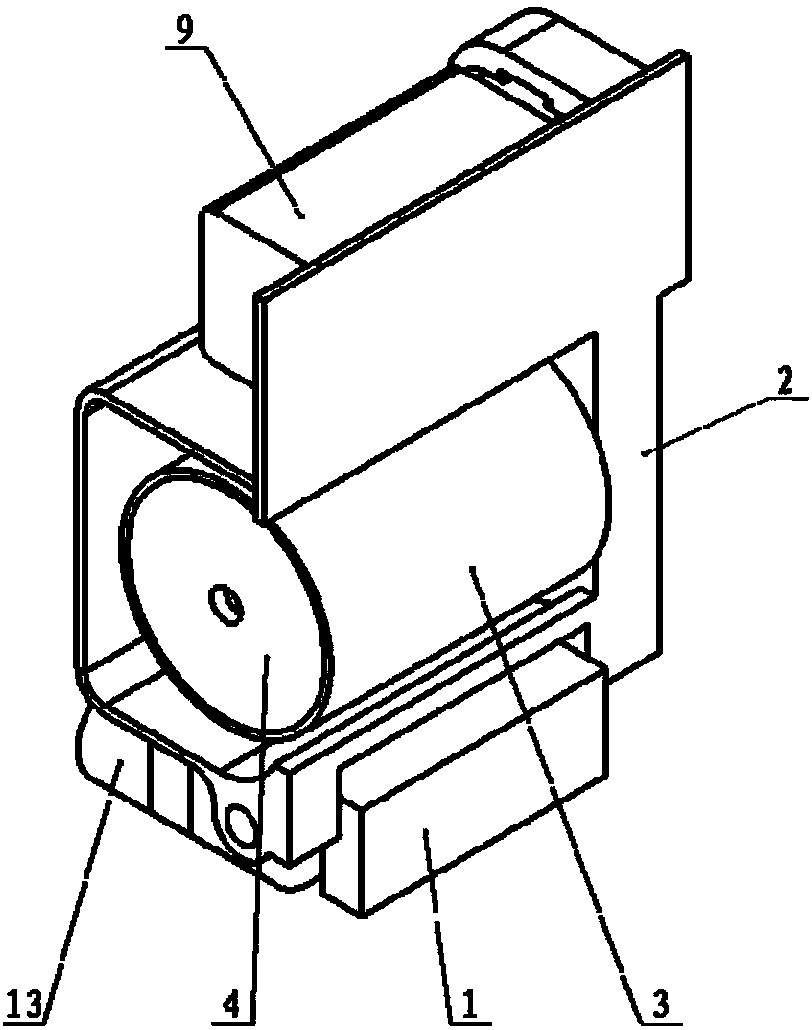

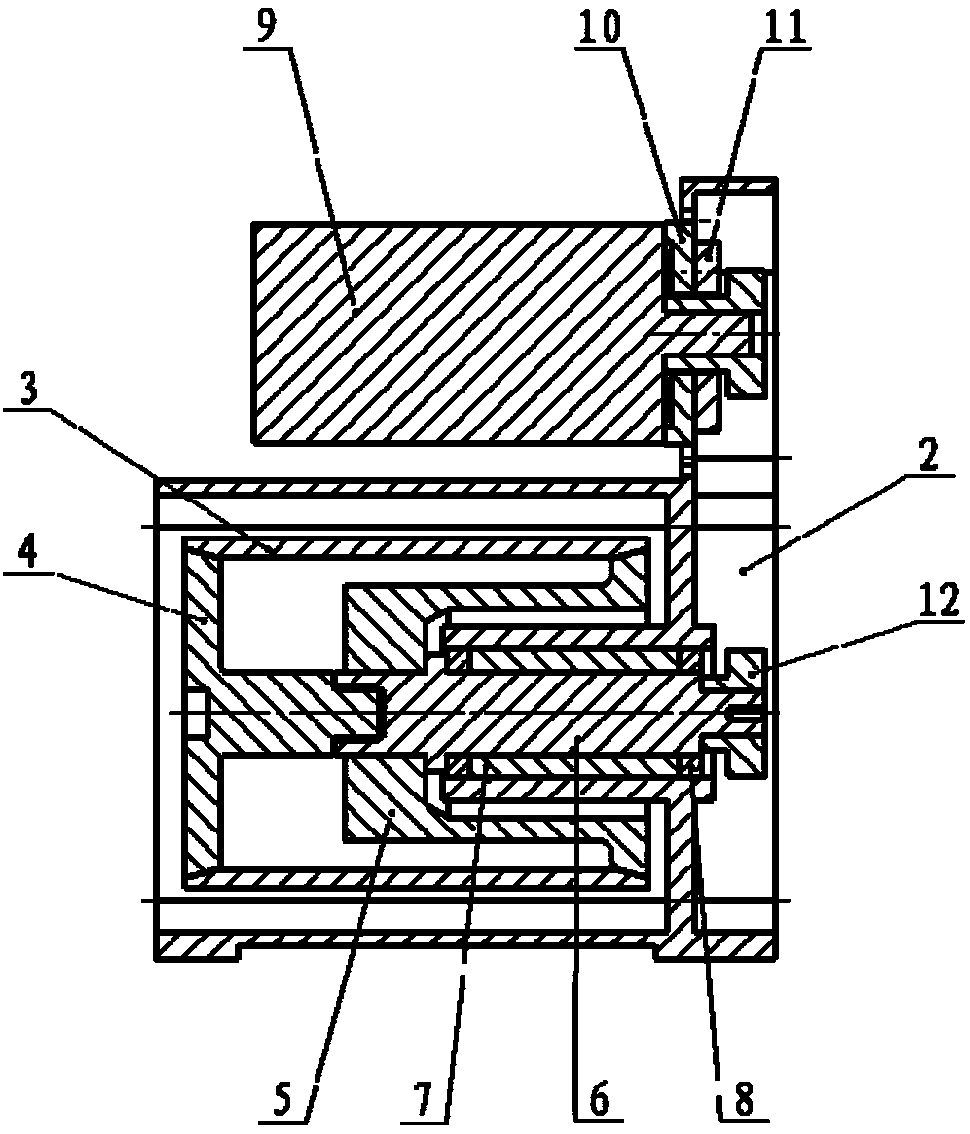

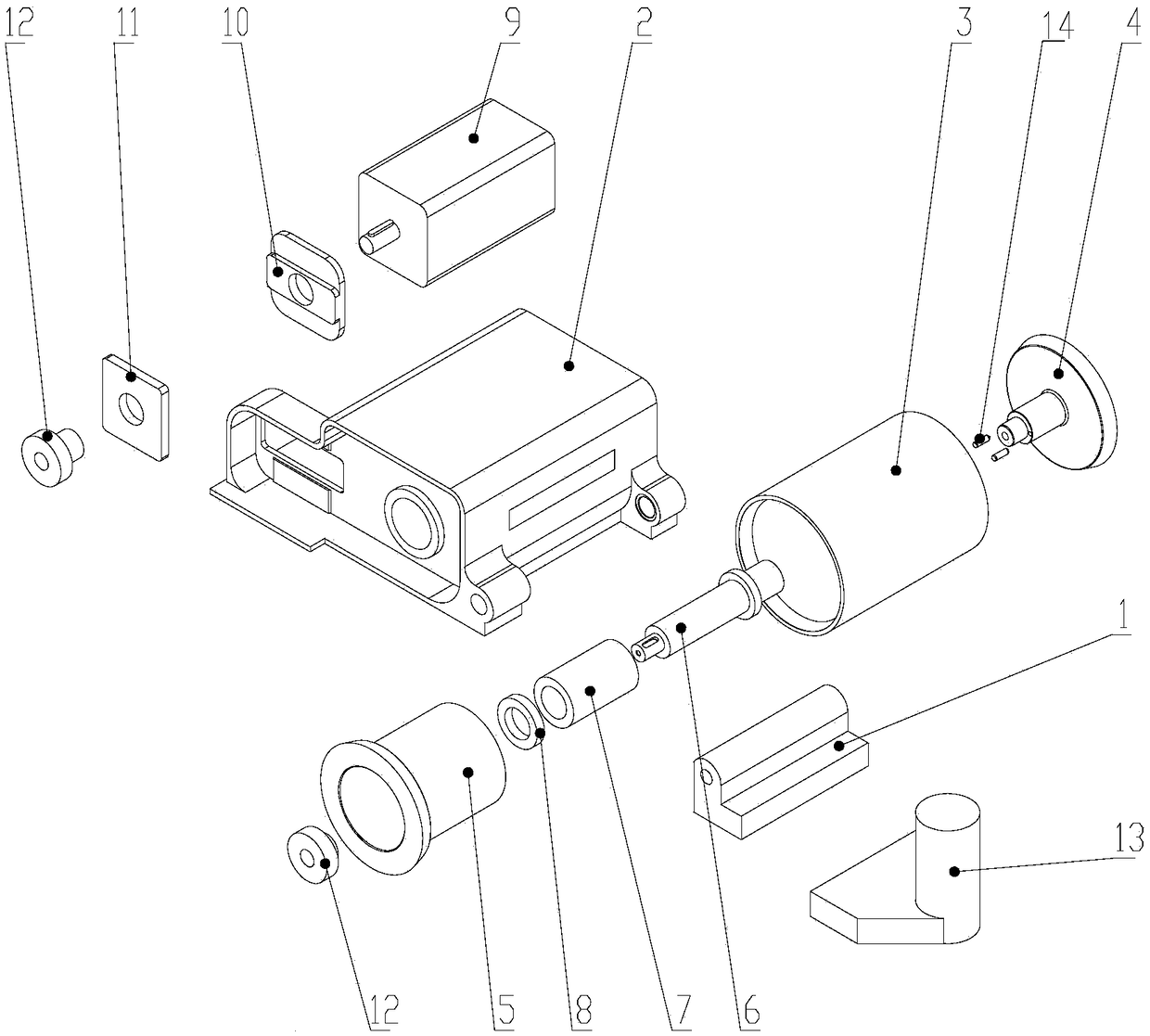

[0024] A kind of cutting machine sharpening device of the present invention is described in detail below in conjunction with accompanying drawing:

[0025] like figure 1 , figure 2 and image 3 As shown, a kind of sharpening device for a wire cutter of the present invention includes a grinding wheel 3, a grinding wheel shaft 6, a pressing disc 4, a support disc 5 and a grinding wheel seat 2: the grinding wheel seat 2 has a function for setting the sharpening wheel The installation space of the grinding wheel 3; the grinding wheel shaft 6 is rotatably installed on the grinding wheel seat 2; the pressing disc 4 and the supporting disc 5 are respectively fixedly connected with the grinding wheel shaft 6; the two ends of the grinding wheel 3 Clamped by the pressing disc 4 and the supporting disc 5 respectively;

[0026] The grinding wheel 3 of the present invention is included in the grinding wheel seat 2, and is connected to the grinding wheel seat 2 through the pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com