Dye-wet compositely-connected spliced building

A composite connection and assembled technology, which is applied to buildings, building components, building structures, etc., can solve problems such as insufficient compressive strength, insufficient corrosion resistance, and high raw material costs, and achieves easy quality assurance, reduced self-weight, and improved earthquake resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

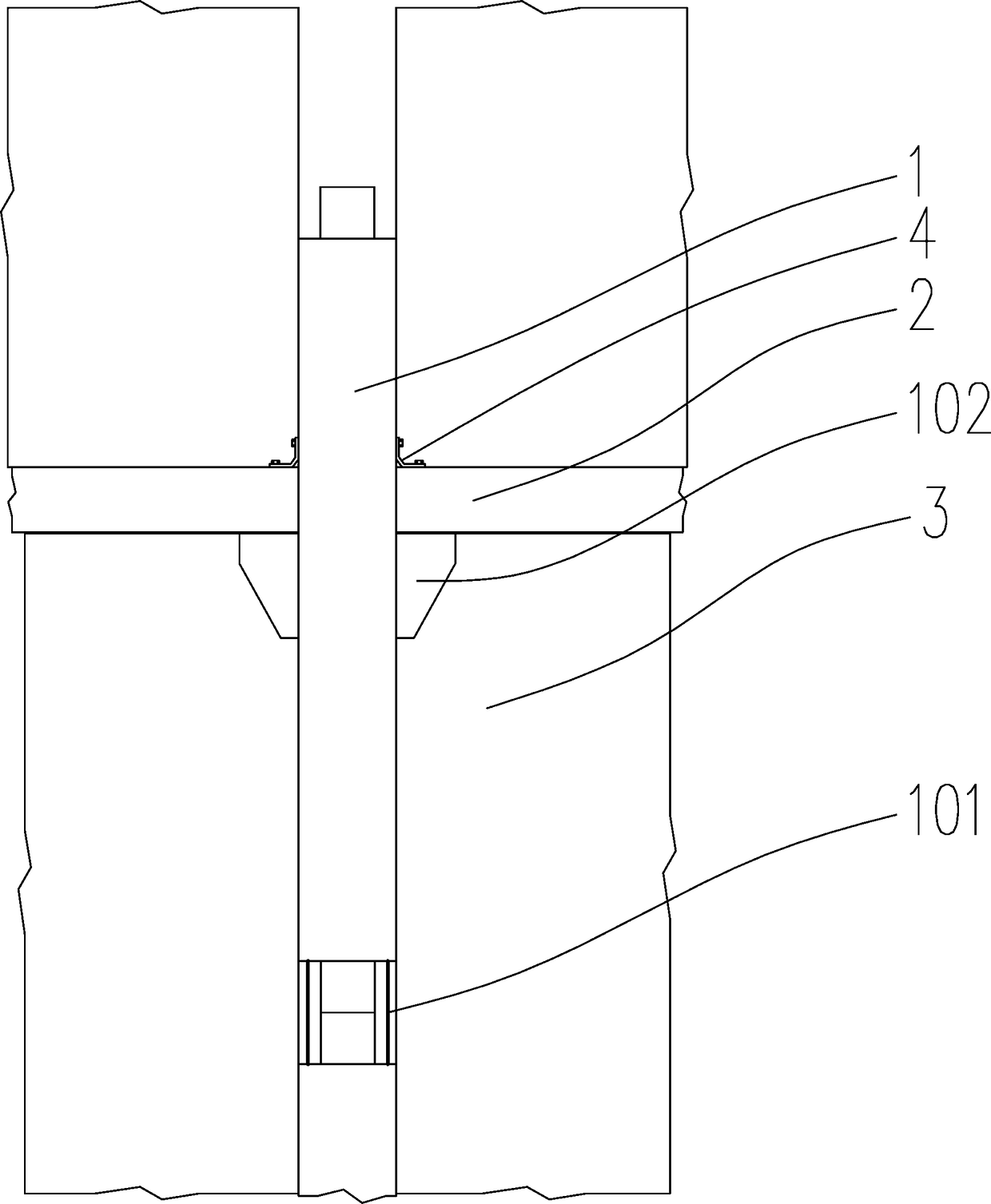

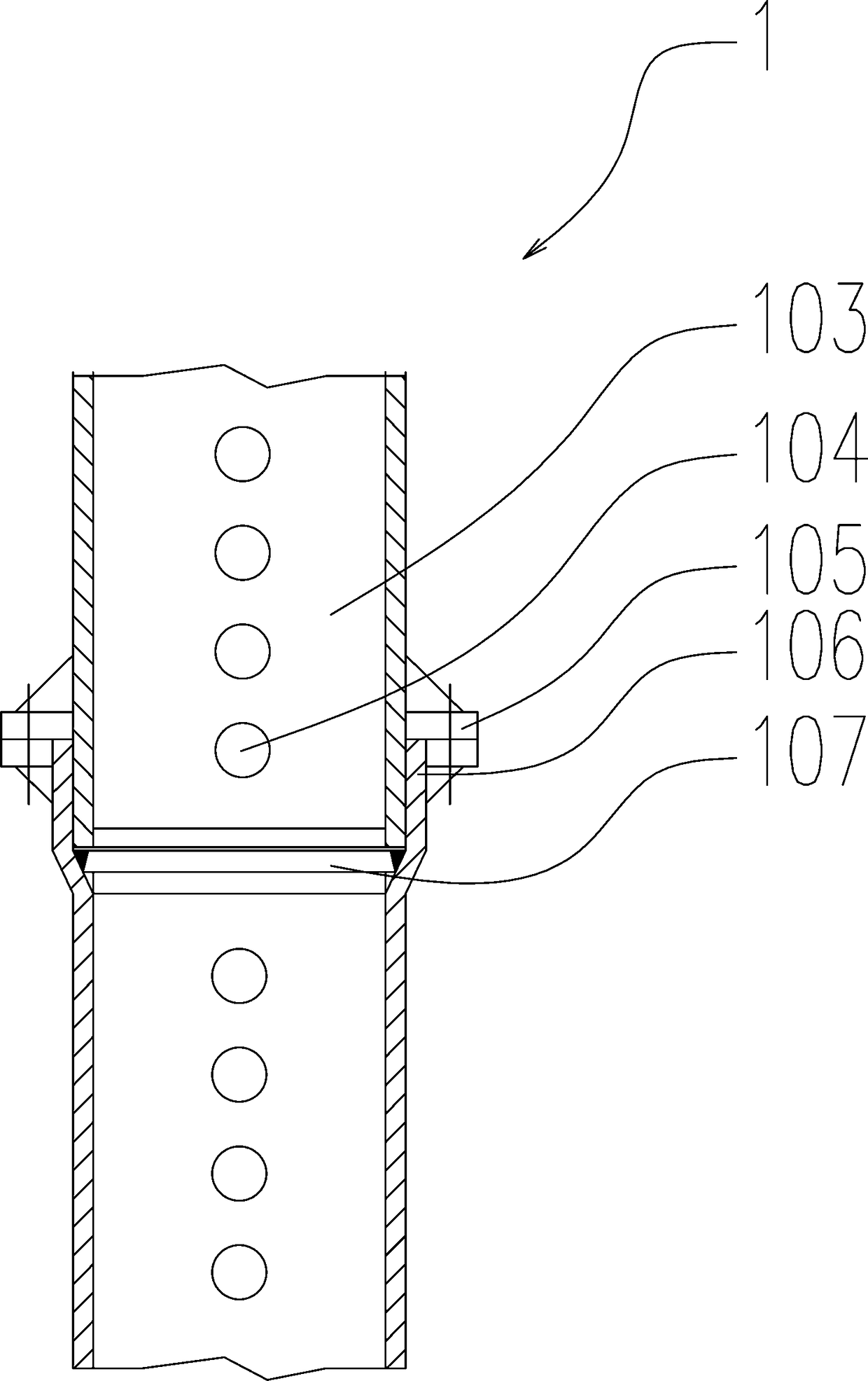

[0031] Such as Figure 1~3 Among them, a dry-wet compound connection assembled structure, the joint position of the column 1 is located between floors, in this example, the joint position can be set according to the construction requirements, it can be set for each floor, or it can be two or three floors Set the connector position. At the position where the reinforcement of the shear wall needs to be connected, the prefabricated column 1 is provided with a reserved transverse reinforcement. A socketed steel pipe 103 is arranged inside the column 1, and a column reinforcement 101 is provided around the socketed steel pipe 103. The inside and outside of the socketed steel pipe 103 are poured with concrete. The ends of the steel pipe 103 and the column reinforcement 101 are exposed, and the ends of the column reinforcement 101 on the upper and lower floors are connected by sleeves or welding; after the hoisting is completed, the exposed part is covered in concrete.

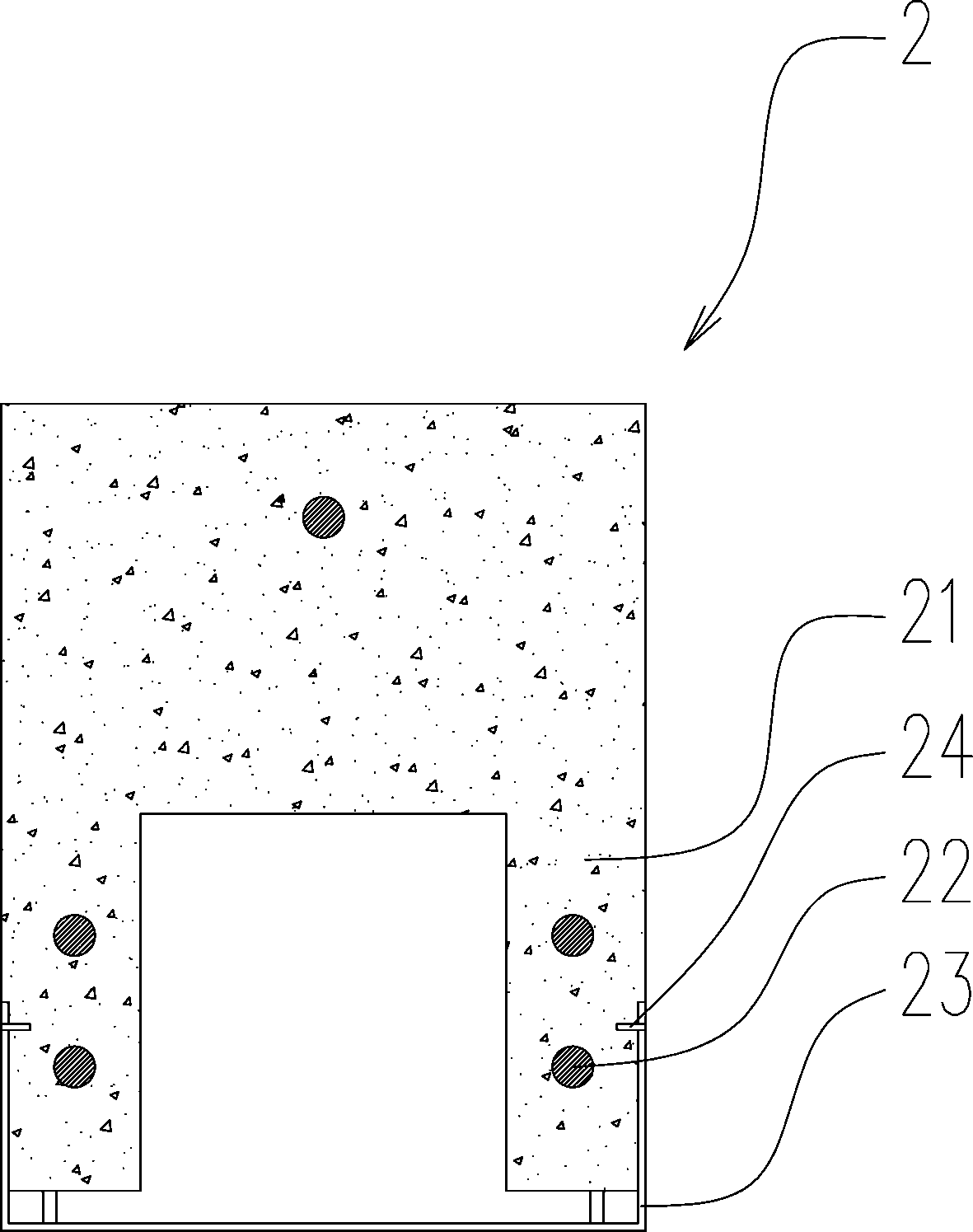

[0032] A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com