Connection joint structure for circular concrete filled steel tubular column and reinforced concrete beam and construction method thereof

A technology for reinforced concrete beams and CFST columns is applied in the connection node structure and construction field of circular CFST columns and reinforced concrete beams, and can solve the difficulties in connecting circular CFST columns and reinforced concrete beams, the connection forms are not rich enough, and the Complex node design and other problems, to achieve the effect of good economic performance, shortened construction period, and fast construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

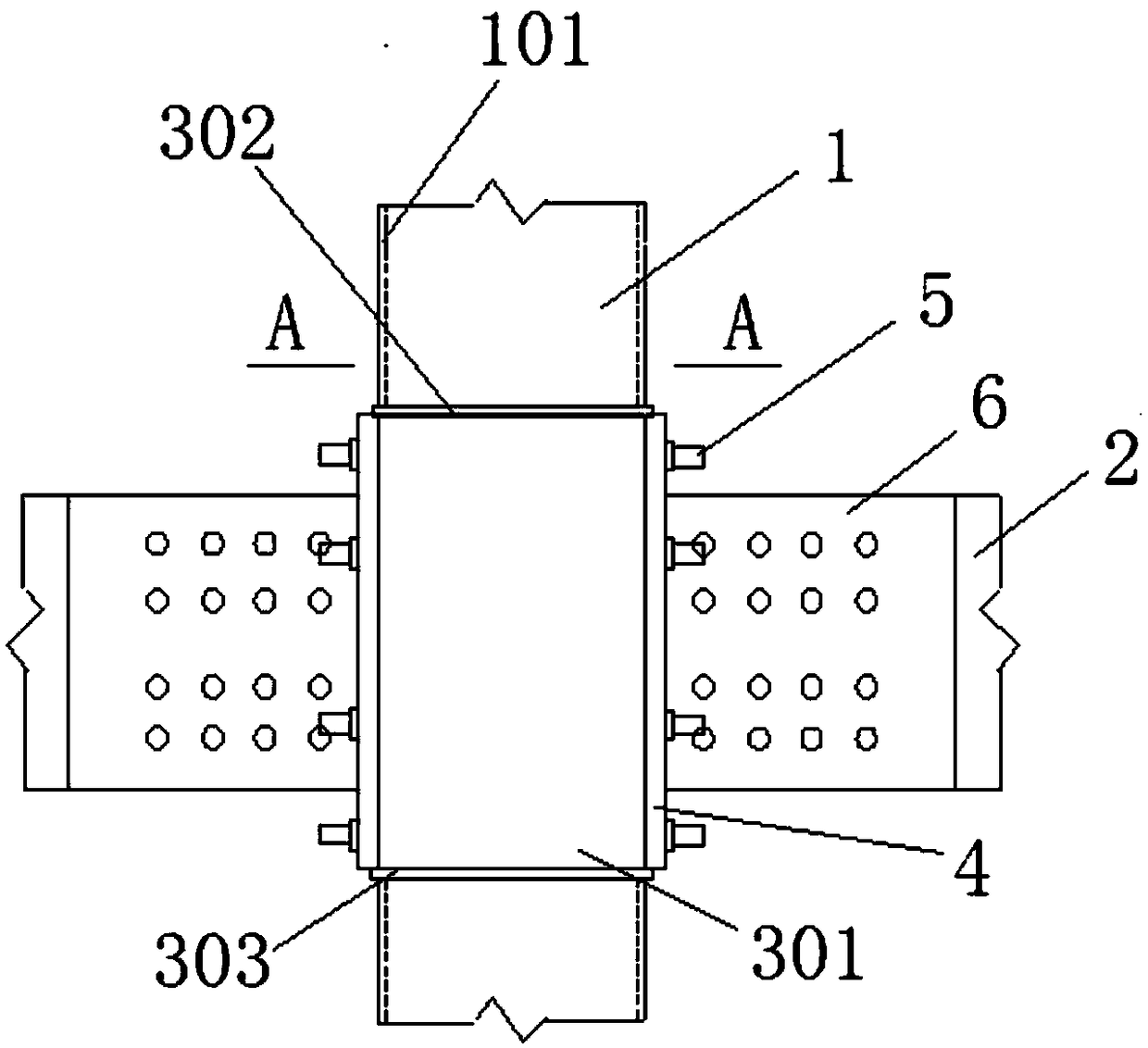

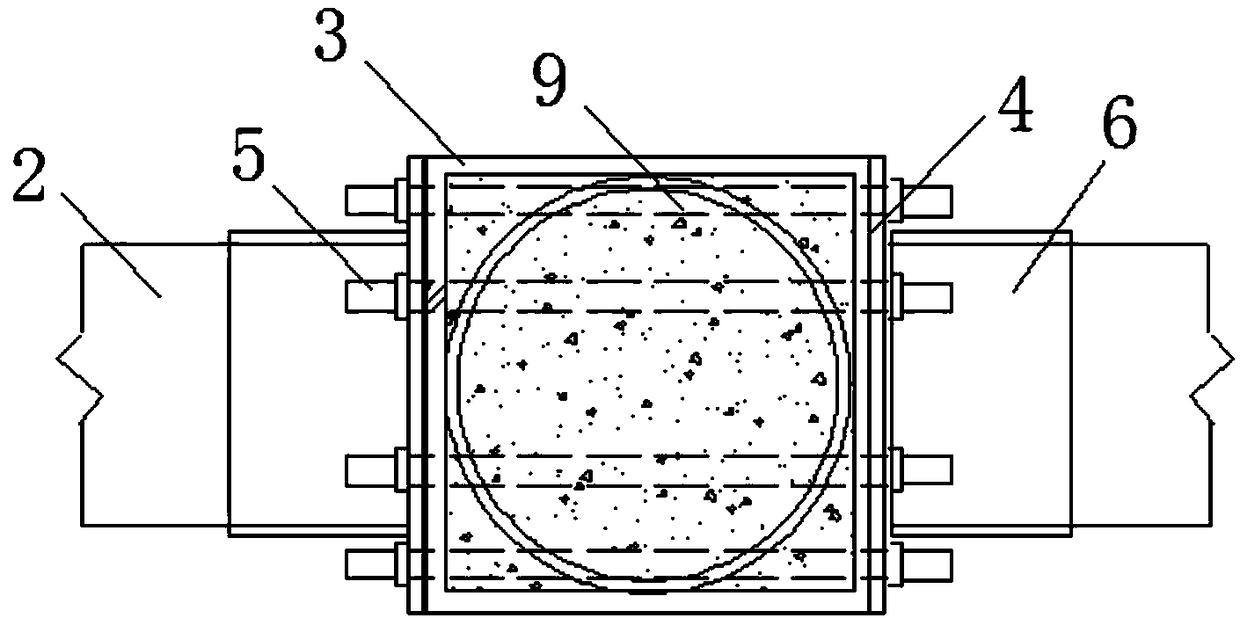

[0037] refer to figure 1 and figure 2 , the embodiment of the present invention provides a connection node structure between a circular steel pipe concrete column 1 and a reinforced concrete beam 2, including: a circular steel pipe 101, a node adapter 3, a stud bolt 5, a steel plate 6 and a reinforced concrete beam 2 The inside of the circular steel pipe 101 is hollow, and concrete is poured inside it to form a circular steel pipe concrete column 1 .

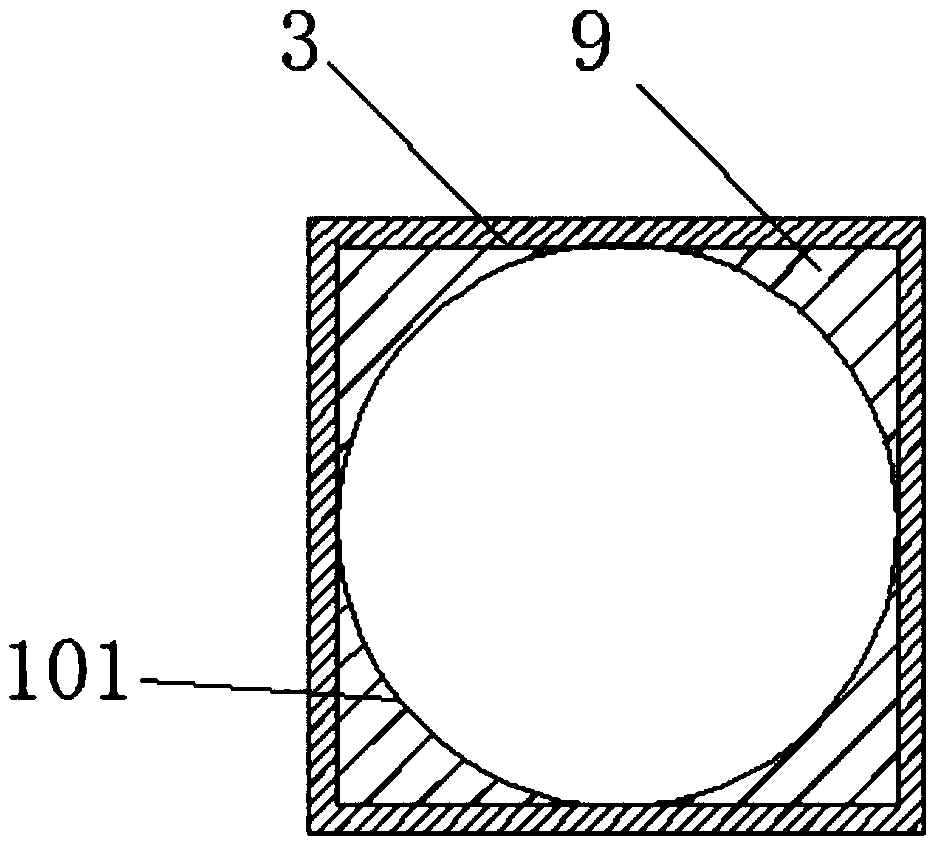

[0038] refer to figure 2 and image 3 , the outer wall of the node adapter 3 is a vertical square steel pipe 301, the vertical square steel pipe 301 is set on the outer wall of the circular steel pipe 101, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com