An acoustic material structure and its assembly method with an acoustic radiation structure

一种声学材料、组装方法的技术,应用在材料领域,达到良好结构声辐射抑制效果、减小影响、减小声波能量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] In order to fully illustrate the technical solutions implemented and used by the present invention to solve the technical problems. The invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the technical solution, implementation of the technical solution and protection scope of the present invention are not limited thereto.

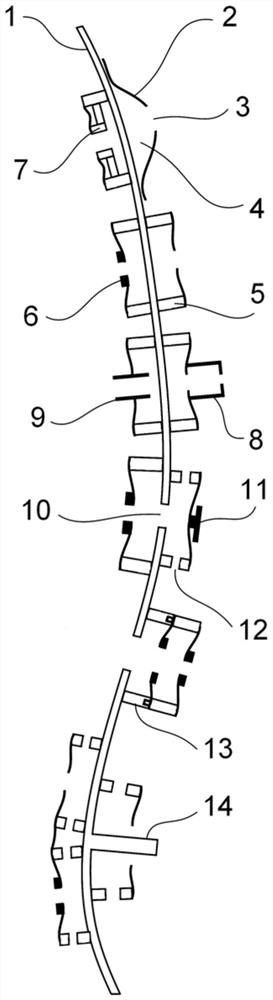

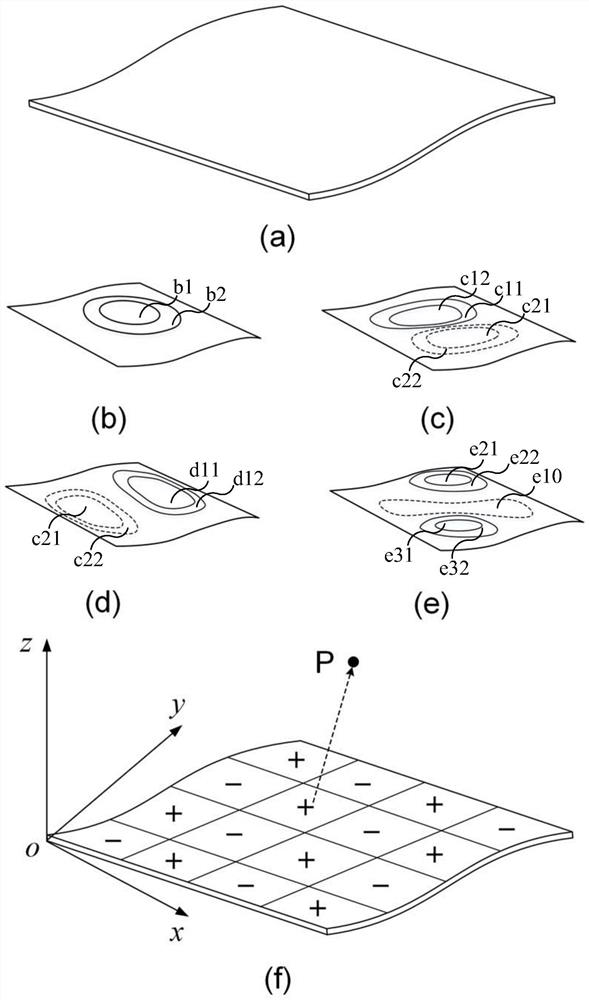

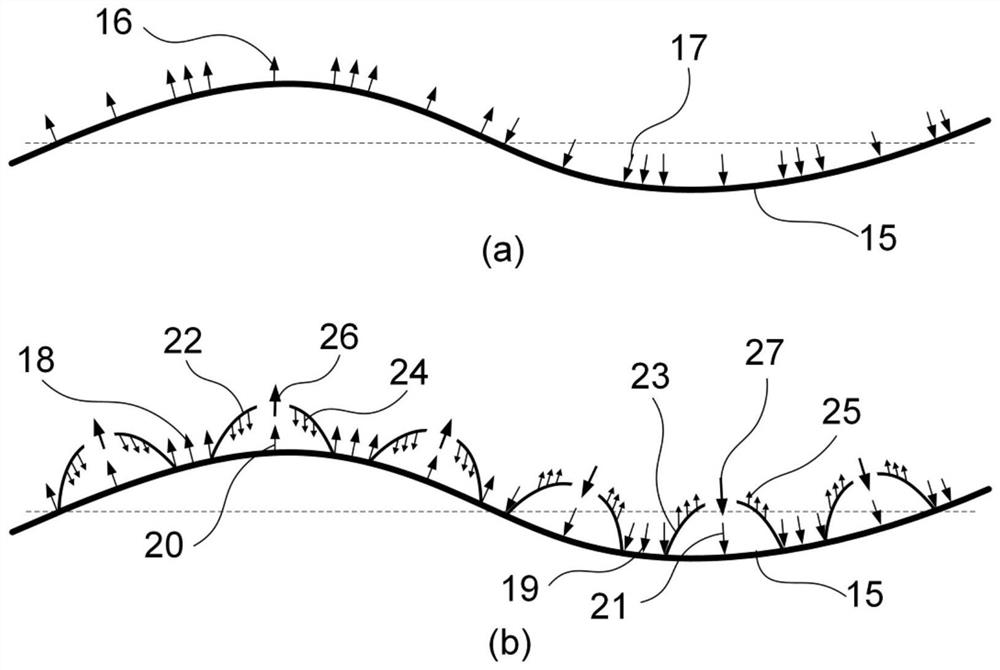

[0121] figure 1 It is a generalized structural schematic diagram of the acoustic material structure of the present invention attached to the surface of the acoustic radiation structure. The acoustic material structure is used to attach to the surface of the sound radiation structure 1, the acoustic material structure includes an acoustic unit, the acoustic unit has an opening 3, the opening 3 runs through the acoustic unit, and the acoustic unit includes a sheet 2. There is a cavity 4 between the sheet 2 and the sound radiation structure 1 , and the cavity 4 communicates with the opening 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com