Shadow mask for OLED evaporation, manufacturing method of shadow mask, and manufacturing method of OLED panel

A manufacturing method and shadow mask technology, which are applied in the field of OLED evaporation, can solve the problems of increasing the limit size of sub-pixels, failing to meet the requirements of small-sized and high-resolution OLED panels, and low aperture ratio, so as to reduce the shadow effect, Mechanical stability, mechanical strength, high corrosion resistance, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

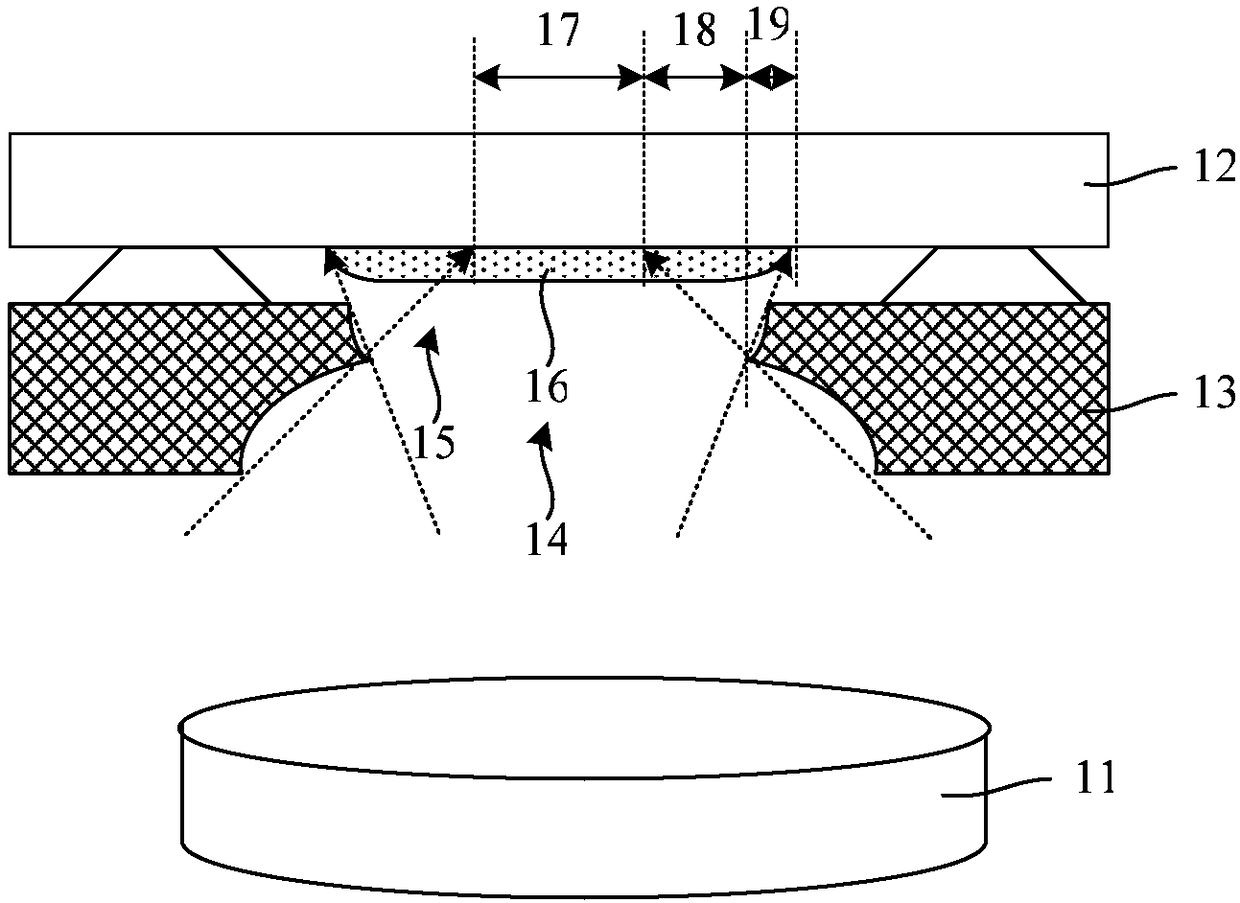

[0060] As mentioned in the background art, existing OLED panels formed by vapor deposition have the problems that the limit size of sub-pixels (light-emitting units) is still enlarged, and the aperture ratio is still low, which cannot meet the requirements of small-sized and high-resolution OLED panels.

[0061] A study of the existing evaporation process found that the size and shape of the openings in the existing metal shadow mask limit the size and aperture ratio of the sub-pixels (light-emitting units) formed by evaporation, that is, in the existing metal shadow mask The size of the opening is still large, so that the sub-pixels (light-emitting units) formed by evaporation using the metal shadow mask are still large, and the shape of the existing metal shadow mask is difficult to guarantee, thus affecting the pixel (light-emitting unit) formed by evaporation. The shape of the unit) affects the aperture ratio.

[0062] Further studies have found that the specific formation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com