Built-in motor rolling brush mechanism and dust collector thereof

A technology of rolling brush and water outlet mechanism, which is applied in the direction of vacuum cleaners, machine parts, suction nozzles, etc., which can solve the problems of difficult sticky dirt removal, inability to deal with ground pollution, and large size of vacuum cleaner heads, so as to save equipment costs and reduce Dimensions and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, the content of the present invention is described in further detail:

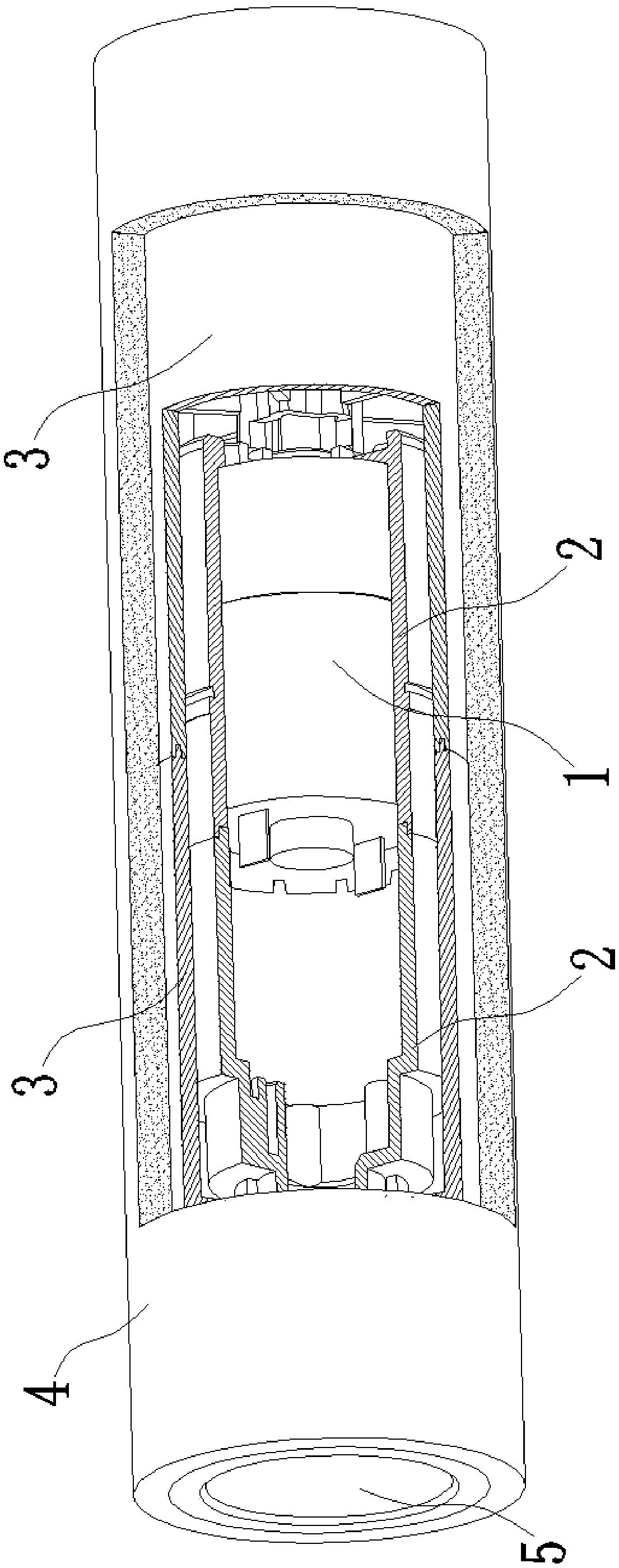

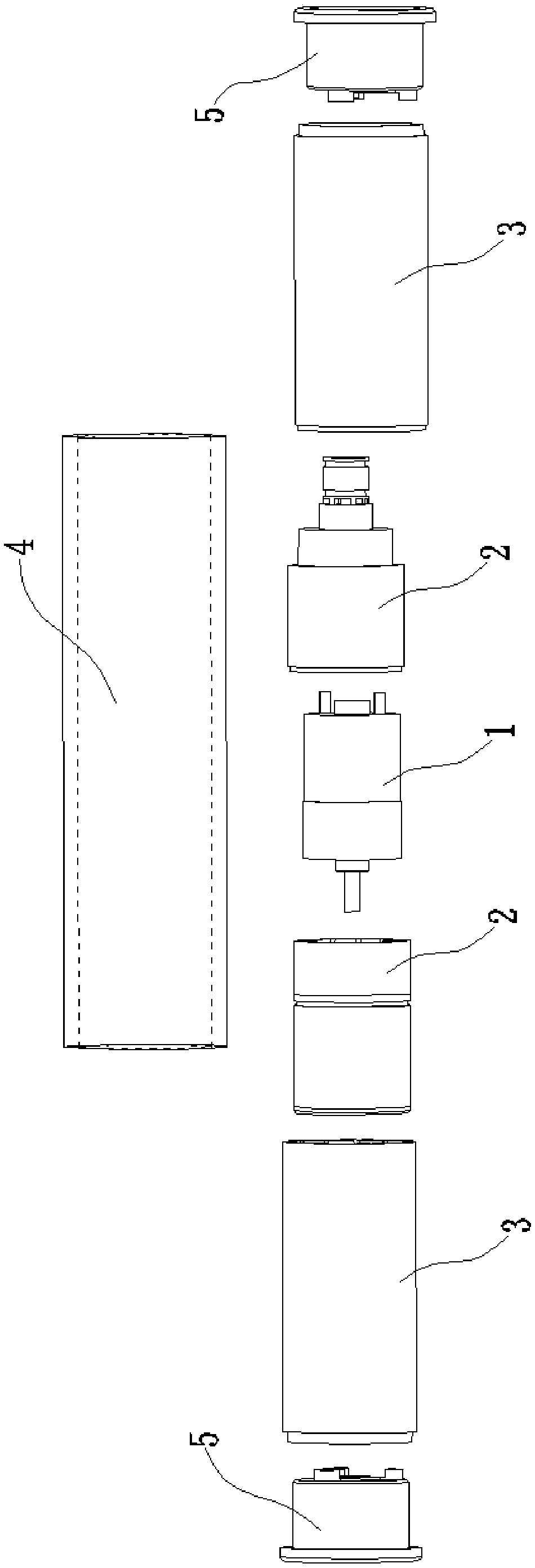

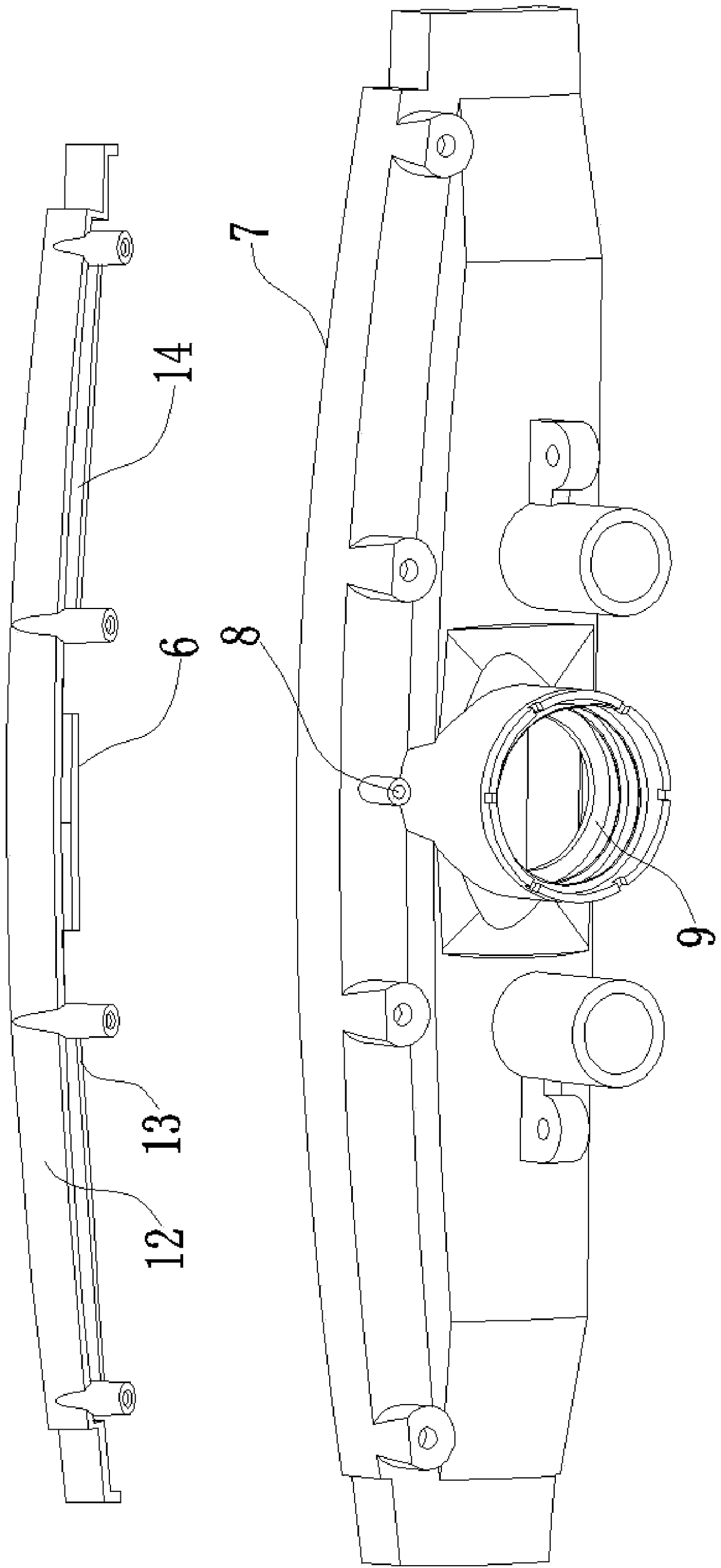

[0027] In order to achieve the purpose of the present invention, a built-in motor rolling brush mechanism includes: a motor 1, which is a rotating motor; an inner cylinder 2, which is in the shape of a hollow cylinder and wraps the motor 1; The circumferential surface is covered with a cloth 4; the water outlet mechanism wets the cloth 4; the inner cylinder 2 and the cloth cylinder 3 are coaxially arranged, and the cloth cylinder 3 is driven by the motor 1 to rotate.

[0028] figure 1 It is a three-dimensional cutaway view. The wiper 4 and the inner cylinder 2 can be glued or glued together. The wiper 4 itself is a flexible fixed non-woven fabric material. of.

[0029] The beneficial effect of adopting the above technical solution is that the motor is located inside the rag cylinder, which greatly saves space, reduces the size of the head of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com