Artificial tooth adhesive composition and preparation method thereof

A composition and adhesive technology, applied in dental preparations, pharmaceutical formulations, tooth irregularity detection/measurement, etc., can solve the problems of difficult cleaning process, unknown human impact, and difficult to remove, and achieve easy cleaning and adhesion performance. Good and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a kind of preparation method of the denture adhesive composition as described in the technical scheme, comprising:

[0048] It is obtained by mixing water-soluble polymer, alginate, mineral oil and calcium sulfate.

[0049] The present invention has clearly described the specific components and proportions of the water-soluble polymer, alginate, mineral oil and calcium sulfate above, and will not repeat them here.

[0050] The present invention does not limit the mixing method and adding order, as long as those skilled in the art are familiar with it. The present invention is preferably mixed in a mixer, the mixing temperature is preferably 20-35° C.; more preferably 20-30° C.; the mixing time is preferably 2-4 hours; most preferably 3 hours.

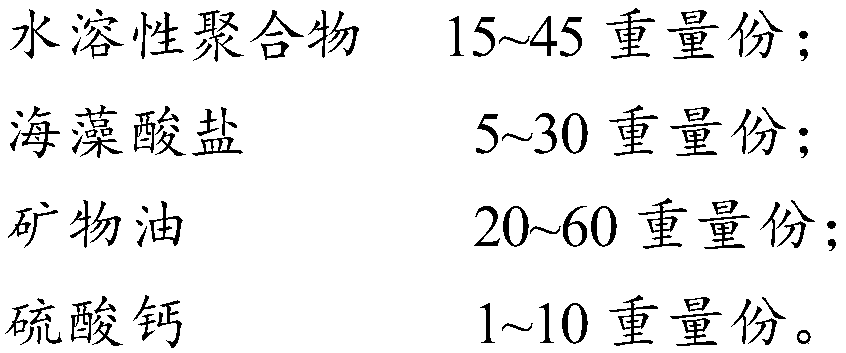

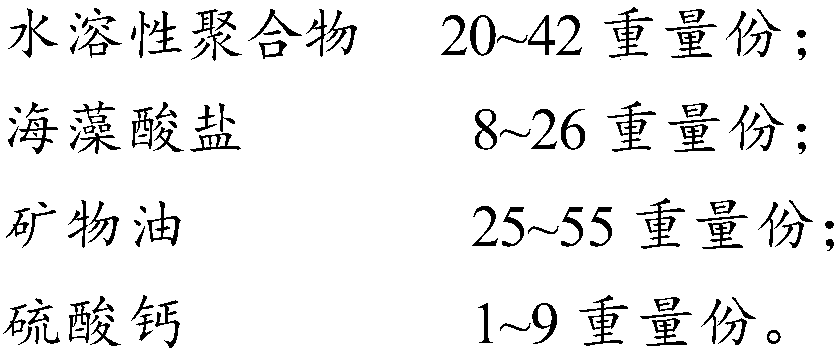

[0051] The invention provides a denture adhesive composition, which comprises: 15-45 parts by weight of water-soluble polymer; 5-30 parts by weight of alginate; 20-60 parts by weight of mineral oil...

Embodiment 1

[0055] The following components were stirred at room temperature for 3h to form a paste (mass%):

[0056] Karaya Gum 40%

[0057] Sodium Alginate 20%

[0059] White oil 30%

[0060] Liquid Paraffin 9%

[0061] Mix the above ingredients to make a paste denture adhesive.

[0062] The performance of the prepared denture adhesive was measured, and the result was: the adhesion strength test was above 6KPa, and the adhesion time lasted for more than 10 hours when used in the oral cavity, and it could be cleaned by brushing three times without residue.

Embodiment 2

[0064] The following components were stirred at room temperature for 3h to form a paste (mass%):

[0065] Sodium Carboxymethyl Cellulose 38%

[0066] Magnesium Alginate 22%

[0068] White oil 30%

[0069] Polyethylene glycol 8%

[0070] The performance of the prepared denture adhesive was measured, and the result was: the adhesion strength test was above 6KPa, and the adhesion time lasted for more than 10 hours when used in the oral cavity, and it could be cleaned by brushing three times without residue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com