A kind of ceramic bond diamond grinding wheel with low temperature thermosetting adhesion layer and preparation method thereof

A ceramic bond, low temperature heat technology, used in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of grinding wheel bursting, abrasive waste, etc., to achieve low abrasive cost, simple and efficient production process, saving The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

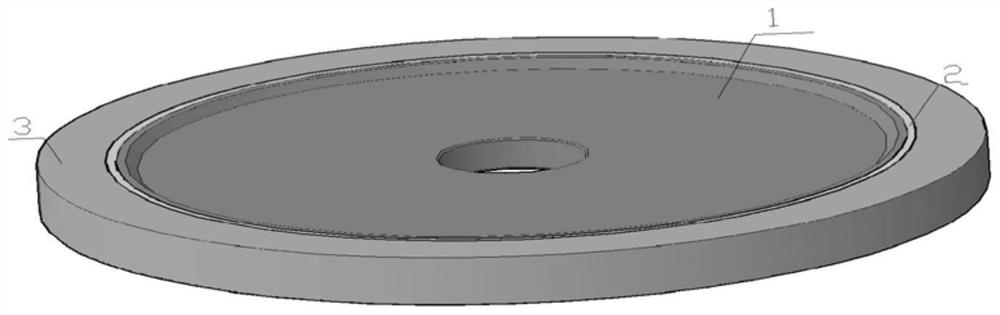

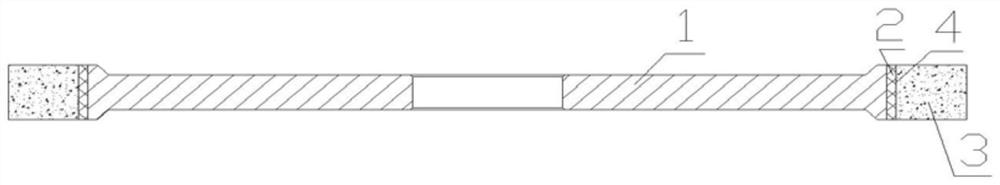

[0027] see Figure 1-2 As shown, a vitrified bonded diamond grinding wheel with a low-temperature thermosetting coating includes a substrate 1 , a low-temperature thermosetting coating 2 , an abrasive layer 3 and a high-strength structural adhesive 4 .

[0028] The above-mentioned preparation method of the vitrified bond diamond grinding wheel with low-temperature thermosetting type attached layer is as follows:

[0029] For the production of the substrate attachment layer, put the substrate into the mold so that the attachment layer material can directly contact the outer circle of the substrate; the white corundum, aluminum oxide, zinc oxide, and phenolic resin powder in the attachment layer raw materials are in a mass ratio of 1:6 :5:3 After mixing evenly, feed the material to the mold with a molding density of ρ=1.8, and then heat press it on a hot press with a pressure of 30t and 200°C for 20 minutes, so that the attached layer material is solidified on the outer circle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com