Processing method of environment-friendly boards

A processing method and plate technology, which are applied in wood processing appliances, wood heating, wood treatment and other directions, can solve the problems of unsafe and environmentally friendly crack prevention methods, poor crack prevention effect, and easy deformation of plates, and achieve good crack prevention effect. Reduced cracking rate and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

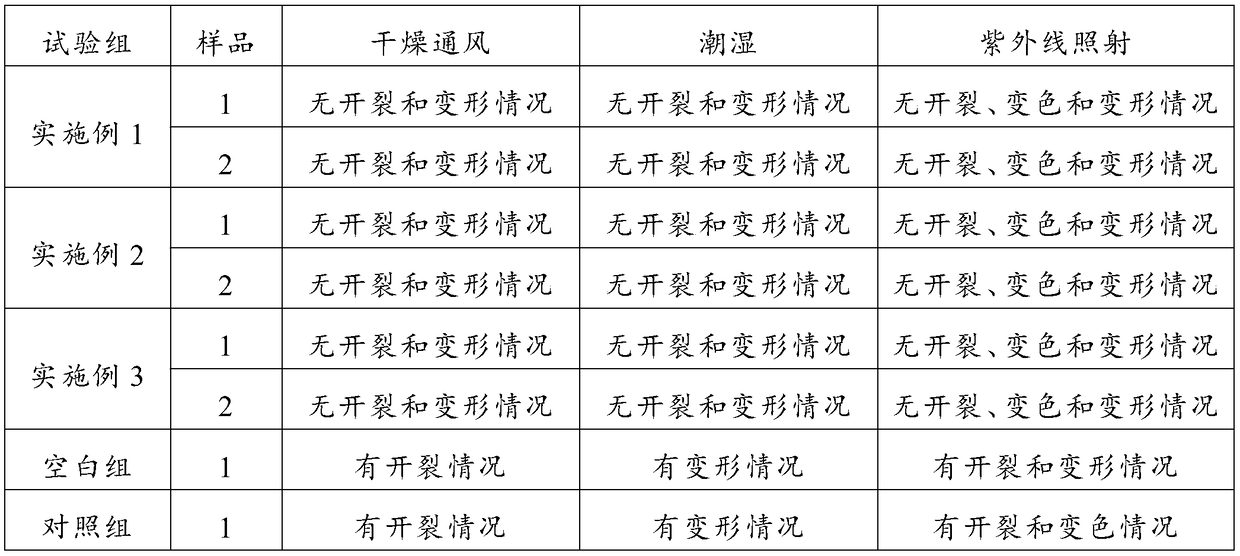

Examples

Embodiment 1

[0040] The processing method of the environment-friendly plate provided by the present invention comprises the following steps;

[0041] (1) Raw wood treatment

[0042] Take the pine log, dry in the shade until the moisture content of the wood is lower than 50%, then cut the log into a 20cm×10cm board, the thickness of the board is 5cm, and set aside;

[0043] (2) Plate drying

[0044] Take the plate described in step (1), dry it with reduced pressure drying method for 6 days, get the dried plate, and set it aside; the drying pressure is 40kpa, and the temperature is 40°C;

[0045] (3) Anti-crack pretreatment

[0046] Take the dry plate described in step (2), place it horizontally in the soaking tank, soak the lower quarter of the dry plate in the anti-cracking agent A, and expose the rest of the dry plate to the air until the anti-cracking agent A is dried When the board is absorbed to half the thickness of the board, use steam to heat the board to 120°C for 30 minutes, th...

Embodiment 2

[0058] The processing method of the environment-friendly plate provided by the present invention comprises the following steps;

[0059] (1) Raw wood treatment

[0060] Take the pine log, dry in the shade until the moisture content of the wood is lower than 50%, then cut the log into a 20cm×10cm board, the thickness of the board is 3cm, and set aside;

[0061] (2) Plate drying

[0062] Take the board described in step (1), dry it with reduced pressure drying method for 4 days, get the dried board, and set aside; the drying pressure is 10kpa, and the temperature is 50°C;

[0063] (3) Anti-crack pretreatment

[0064] Take the dry plate described in step (2), place it horizontally in the soaking tank, soak the lower quarter of the dry plate in the anti-cracking agent A, and expose the rest of the dry plate to the air until the anti-cracking agent A is dried When the board is absorbed to half the thickness of the board, use steam to heat the board to 110°C for 60 minutes, then ...

Embodiment 3

[0076] The processing method of the environment-friendly plate provided by the present invention comprises the following steps;

[0077] (1) Raw wood treatment

[0078] Take the pine log, dry in the shade until the moisture content of the wood is lower than 50%, then cut the log into a 20cm×10cm board, the thickness of the board is 4cm, and set aside;

[0079] (2) Plate drying

[0080] Take the plate described in step (1), dry it with reduced pressure drying method for 5 days, get the dried plate, and set aside; the drying pressure is 30kpa, and the temperature is 45°C;

[0081] (3) Anti-crack pretreatment

[0082] Take the dry plate described in step (2), place it horizontally in the soaking tank, soak the lower quarter of the dry plate in the anti-cracking agent A, and expose the rest of the dry plate to the air until the anti-cracking agent A is dried When the board is absorbed to half the thickness of the board, use steam to heat the board to 115°C for 45 minutes, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com