Control method for sigma-phase precipitation of ER316L austenitic stainless steel wire rods

An austenitic stainless steel, ER316L technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of billet corner cracking, low rolling speed, pitting corrosion resistance and crevice corrosion resistance. The effect of good drawing performance and optimized rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] 1) Preparation of austenitic stainless steel ER316L forging billet

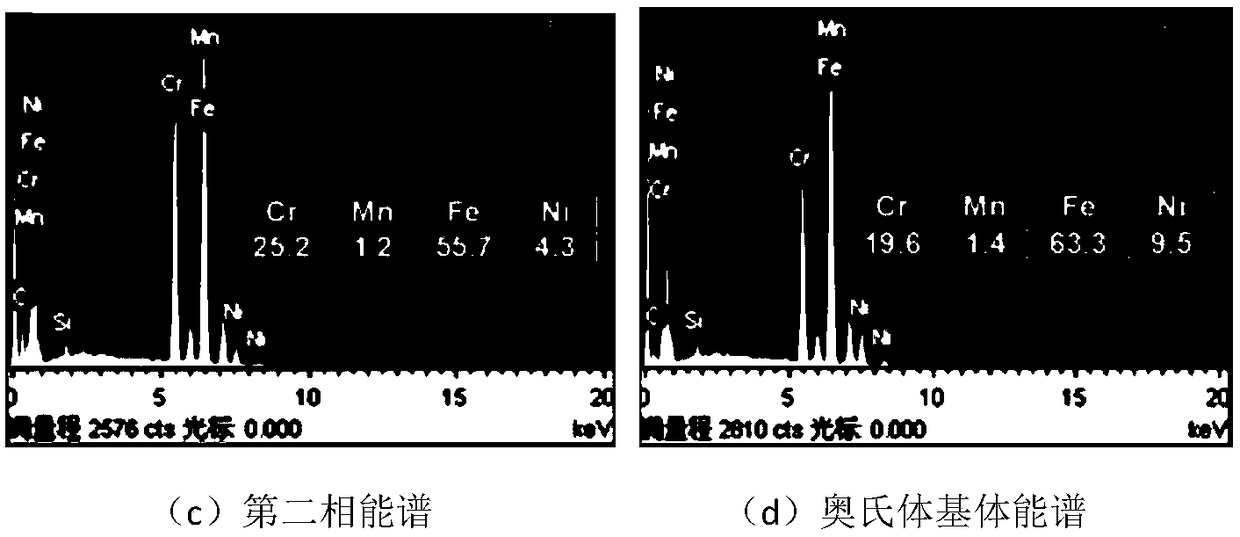

[0037] The austenitic stainless steel ER316L ingot was smelted in a 4.5t German ALD vacuum induction furnace, and its chemical composition is shown in Table 1. The steel ingot was forged into a billet after electroslag remelting, and the size after surface grinding was 140×140×1600mm.

[0038] Table 1

[0039]

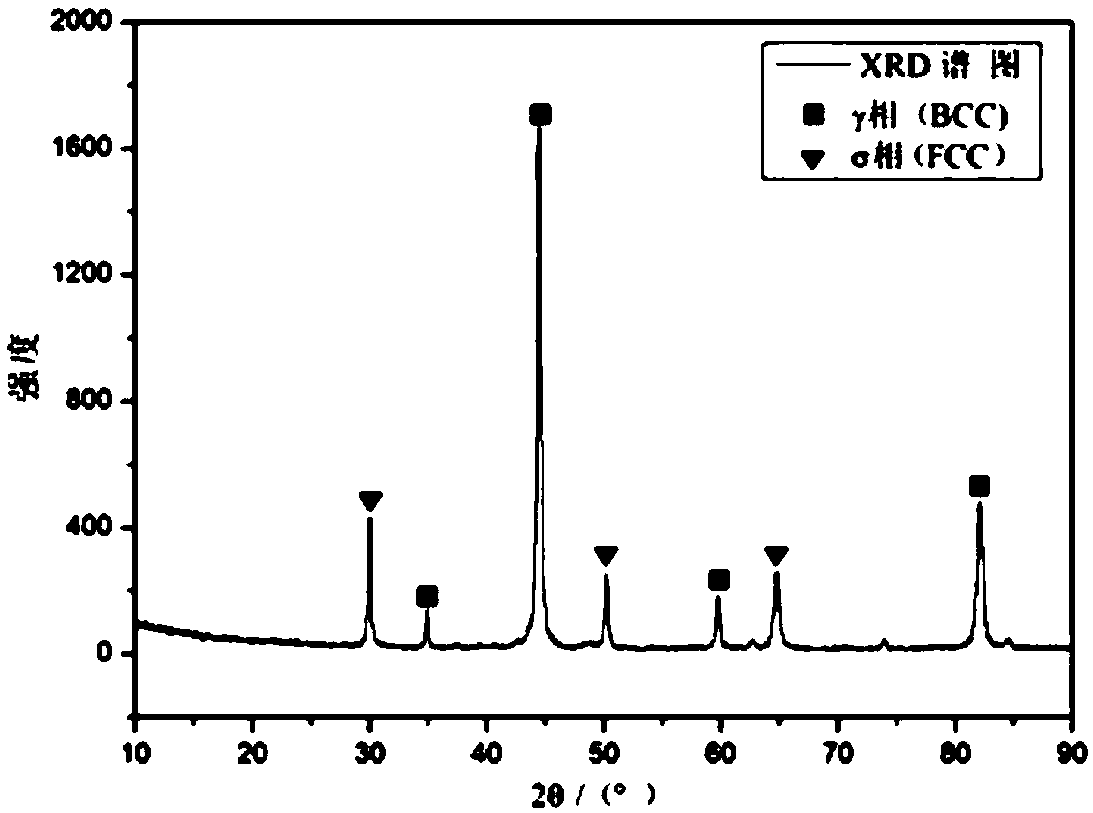

[0040] 2) Solution heat treatment and high temperature compression treatment of test materials

[0041] The sampled material from the flying shear station in the rough rolling stage was processed into a solution heat treatment test sample with a size of 20×20×20mm, which was heated to a temperature of 850, 950, 1000, and 1100°C in a Nabertherm N31 / H box-type resistance furnace, respectively. Water quenching after 30 min of heat preservation. The material sampled at the flying shear station in the rough rolling stage was processed into a high-temperature compression test sample with a size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com