Tin bronze lining and preparation method thereof

A technology of tin bronze and bushing, applied in the field of tin bronze bushing and its preparation, can solve the problems of relying on the heat absorption capacity of metal molds, limited, etc., and achieve the effects of low production cost, reasonable casting process and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

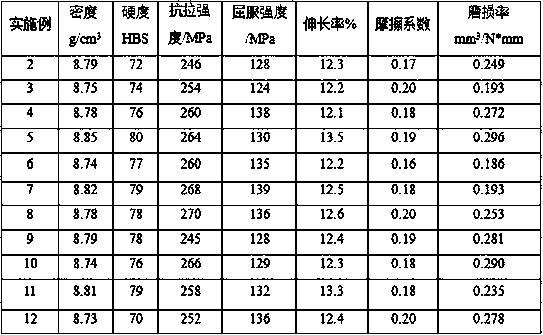

Examples

Embodiment 1

[0024] The invention provides a tin bronze bushing, which is mainly made of the following raw materials in weight percentage: Sn9%, Pb2.5%, Ni0.6%, Zn2%, Si0.3%, Cu balance.

[0025] The preparation method of described tin bronze bushing, it comprises the following steps:

[0026] Step a, copper alloy smelting; the copper alloy smelting is to weigh Sn, Pb, Ni, Si and Cu according to the process ratio and put them into the furnace for heating, and the heating temperature is controlled at 1200 ° C, so that the furnace charge is melted into copper alloy liquid;

[0027] Step b, deoxidation treatment; the deoxidation treatment is to add 0.08% phosphor copper of the total weight of the molten copper alloy liquid in the molten copper alloy liquid obtained in step a, and carry out uniform stirring by injecting nitrogen to implement deoxidation treatment;

[0028] Step c, mold preheating; the mold preheating is to preheat the casting outer mold and the metal core casting inner mold, ...

Embodiment 2

[0033] The invention provides a tin bronze bushing, which is mainly made of the following raw materials in weight percentage: Sn8.2%, Pb3%, Ni0.5%, Zn1%, Si0.5%, Cu balance.

[0034] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0036] The invention provides a tin bronze bushing, which is mainly made of the following raw materials in weight percentage: Sn8.4%, Pb2.8%, Ni0.6%, Zn1.2%, Si0.4%, Cu balance .

[0037] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com