Full-automatic waste fiber dedusting machine

A technology of waste fiber and dust collector, which is applied in the direction of dust removal, cleaning method using gas flow, textiles and paper making, etc. It can solve the problems of difficult disposal of waste fiber, easy flying of waste fiber, and affecting work efficiency, etc., to achieve unloading Convenience, prevent waste fiber from affecting production, and improve production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

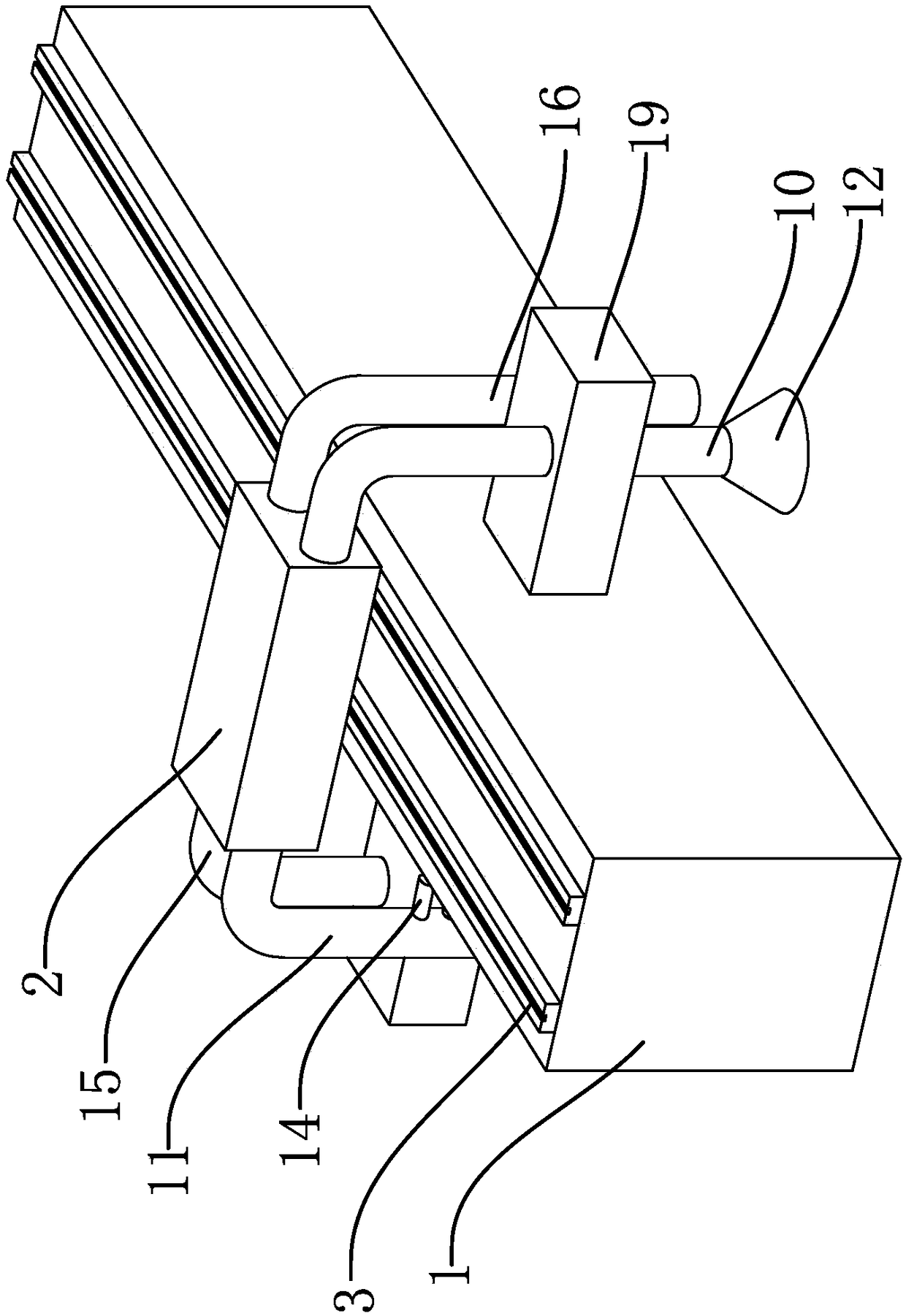

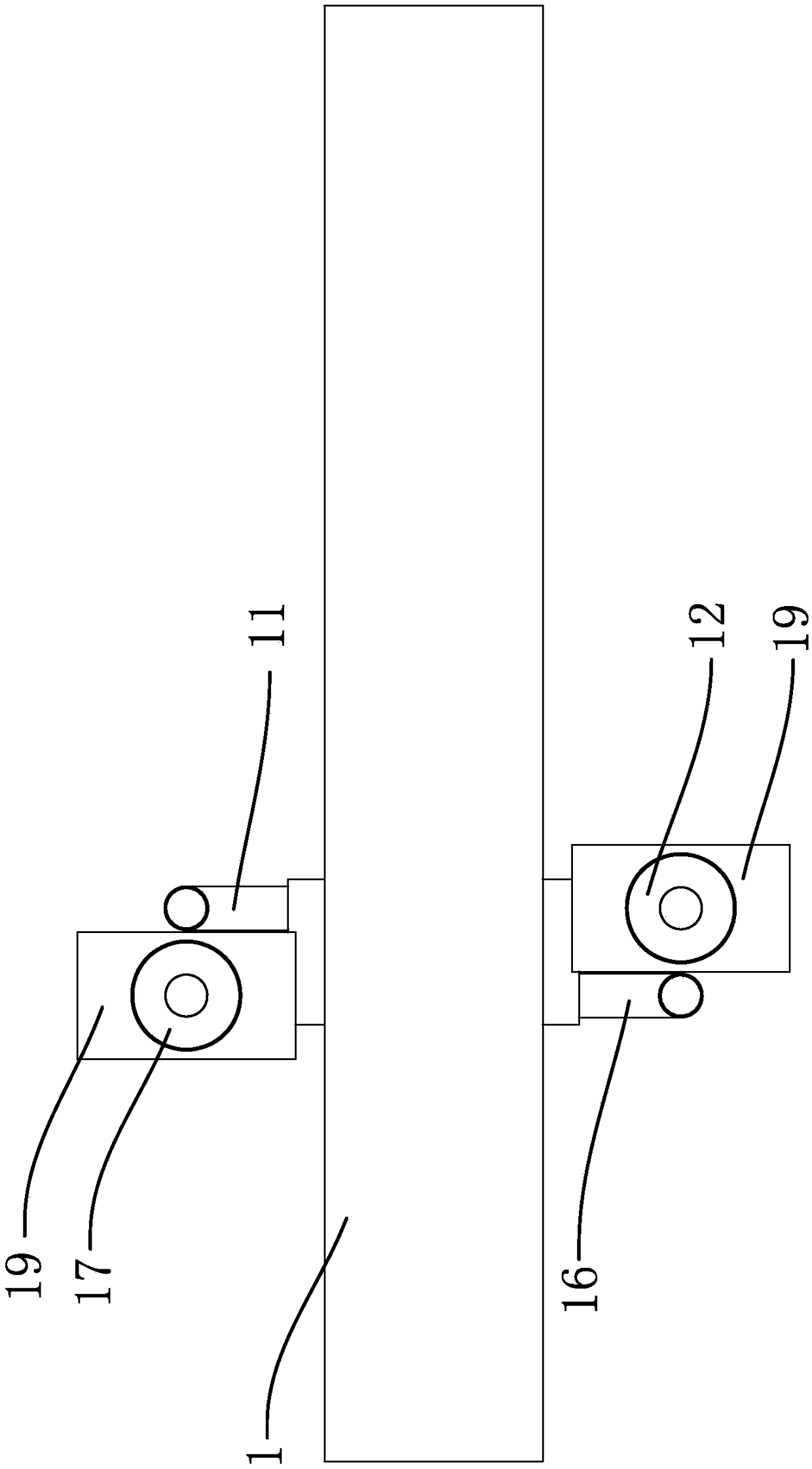

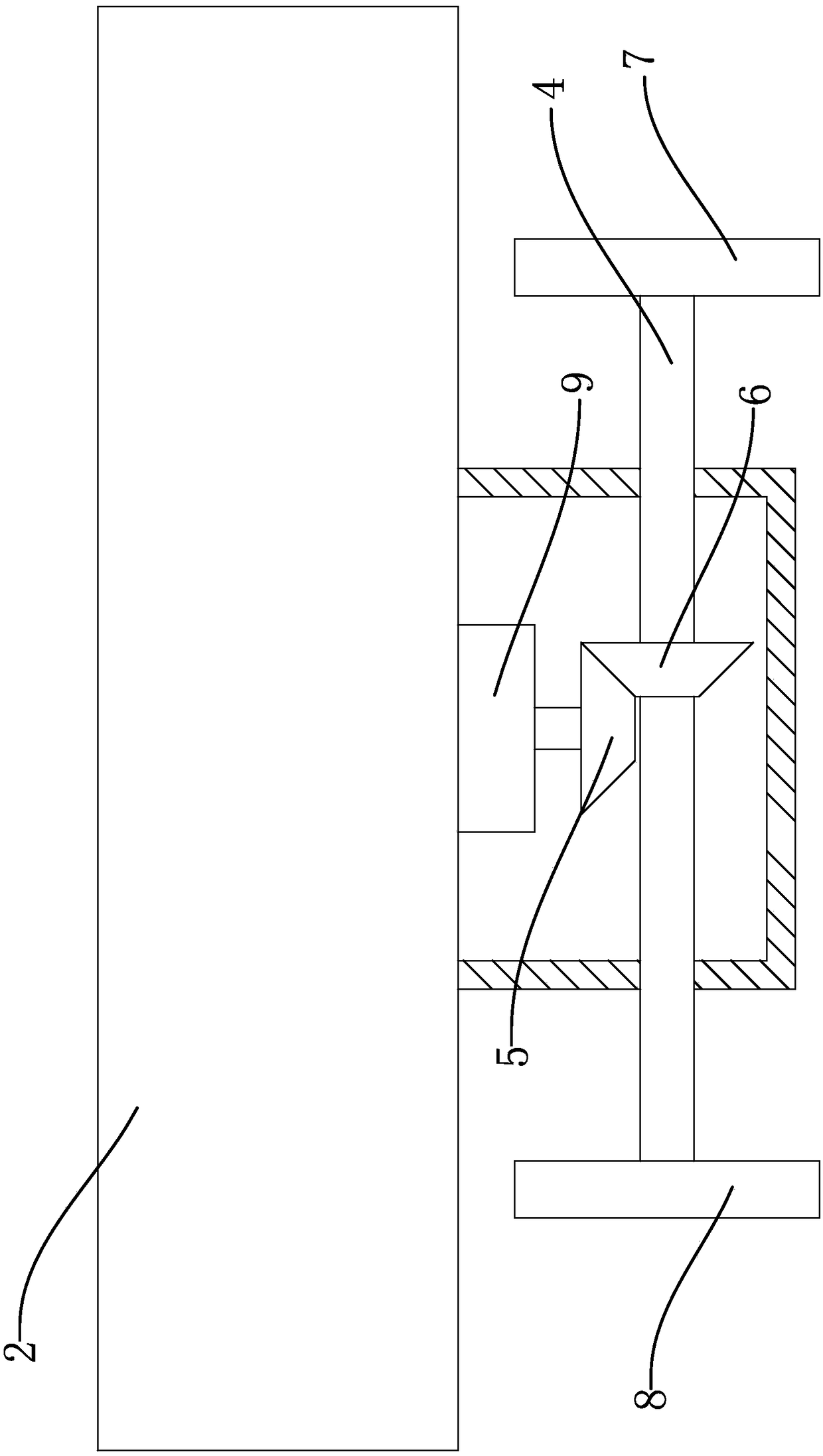

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0027] Such as Figure 1-5 As shown, a fully automatic waste fiber dedusting machine, the coated wire machine includes a frame 1, the fully automatic waste fiber dedusting machine includes a work box 2 and a track 3, the track 3 is horizontally fixed on the top of the frame 1, and the work box 2 slides Set on the track 3, the bottom of the working box 2 has a driving mechanism that can drive it to move back and forth on the track 3, and the working box 2 is provided with a dust removal mechanism that can absorb waste fibers on one side of the frame 1, and the working box 2 is also provided with There is a second dust removal mechanism capable of sucking up the waste fiber on the other side of the frame 1.

[0028] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com