An integrated device for charging and compacting cylindrical cavity, vacuuming, screwing and sealing

A vacuum sealing and vacuuming technology, which is applied in the field of cylindrical cavity charging and compacting, vacuuming, screwing and sealing integrated devices, can solve the problems of low charging accuracy, poor repeatability, and difficulty in ensuring the accuracy of process equipment, etc. Achieve the effect of improving the quality of production products, significant economic benefits, and improving labor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

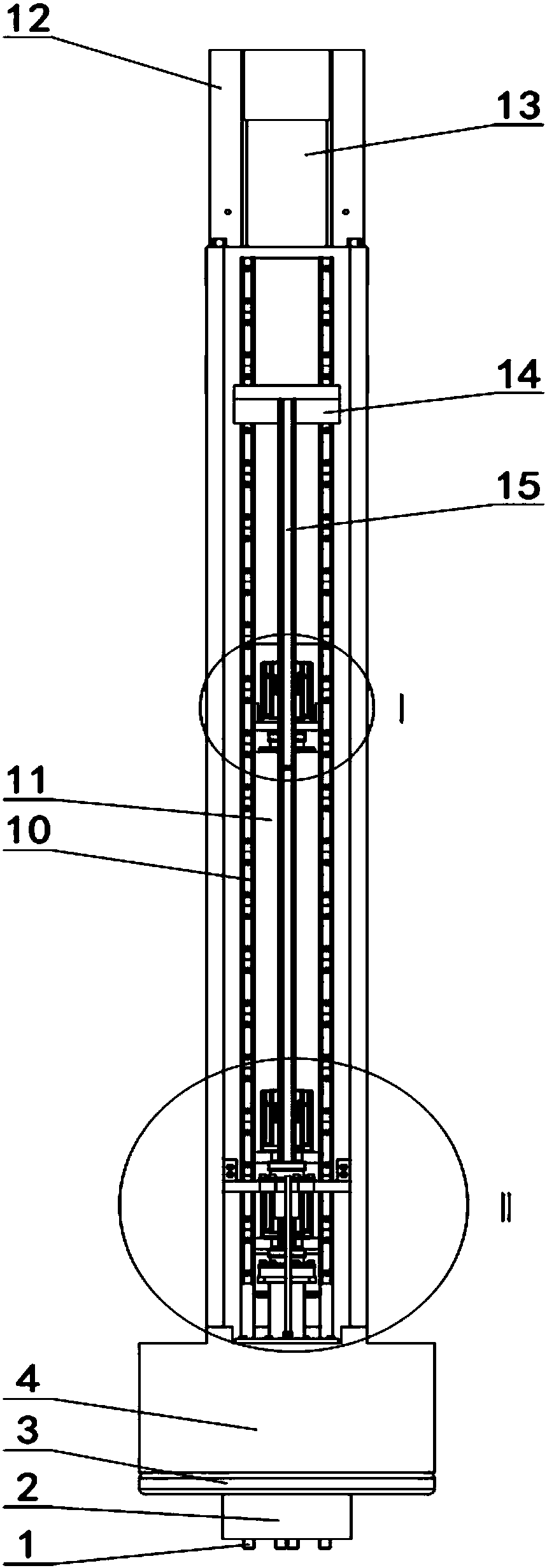

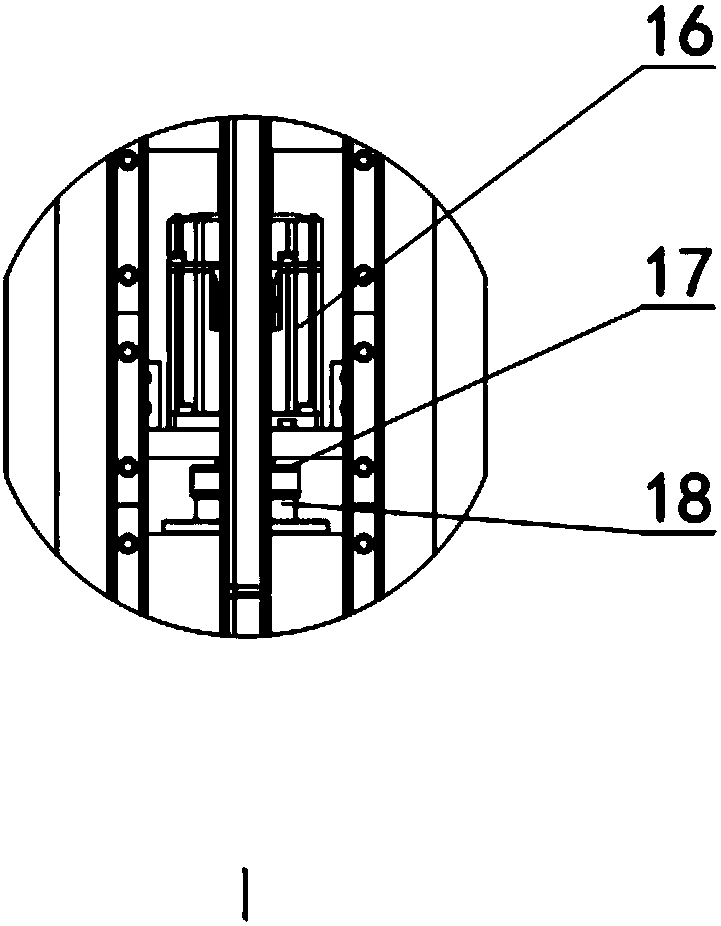

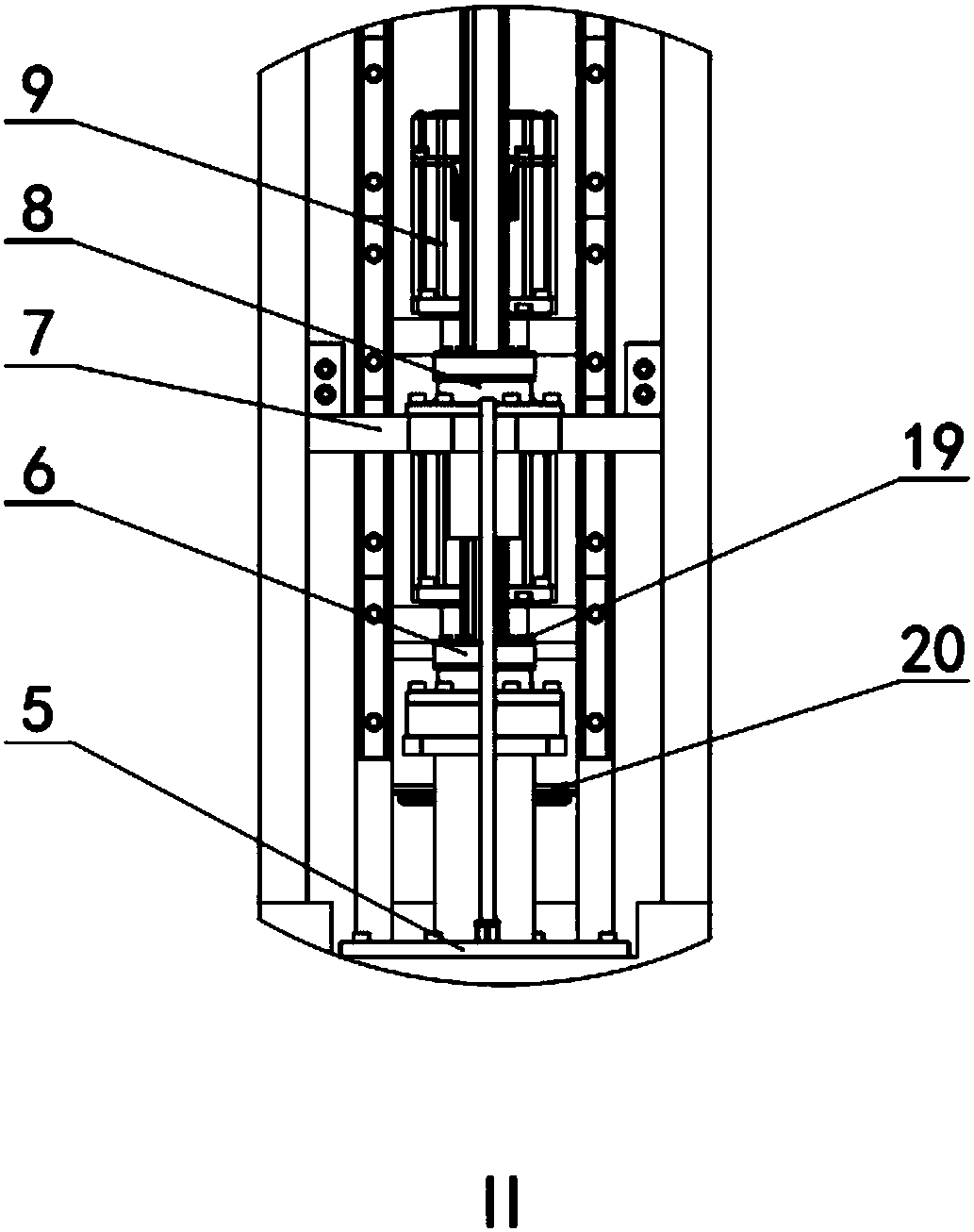

[0023] This embodiment is an integrated device for charging and compacting a cylindrical cavity, vacuuming, screwing and sealing.

[0024] refer to Figure 1-6 , in this embodiment, the integrated device for charging and compressing the cylindrical cavity, vacuuming, screwing and sealing is composed of a control system, a vacuum pump, a workbench, a vacuuming part, a pressing and screwing part, the first dust cover, the second It is composed of two dust-proof covers; the workbench provides support for each component; the control system adopts PMAC+ industrial computer control to control the vacuum part and the compression screw part, and realize the independent work of different mechanism parts according to the needs. The motor transmits power to the lead screw through the transmission belt to realize the up and down telescopic movement of the lead screw, and cooperates with the splined coupling shaft of the lead screw to drive the vacuum sealing cover to move up and down. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com