Method for improving fiber strength of hardwood pulp by utilizing compound enzyme

A technology of fiber strength and broadleaf pulp, applied in the field of papermaking, can solve the problems of reduced strength and high price of softwood pulp, and achieve the effects of improving quality, reducing production costs and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

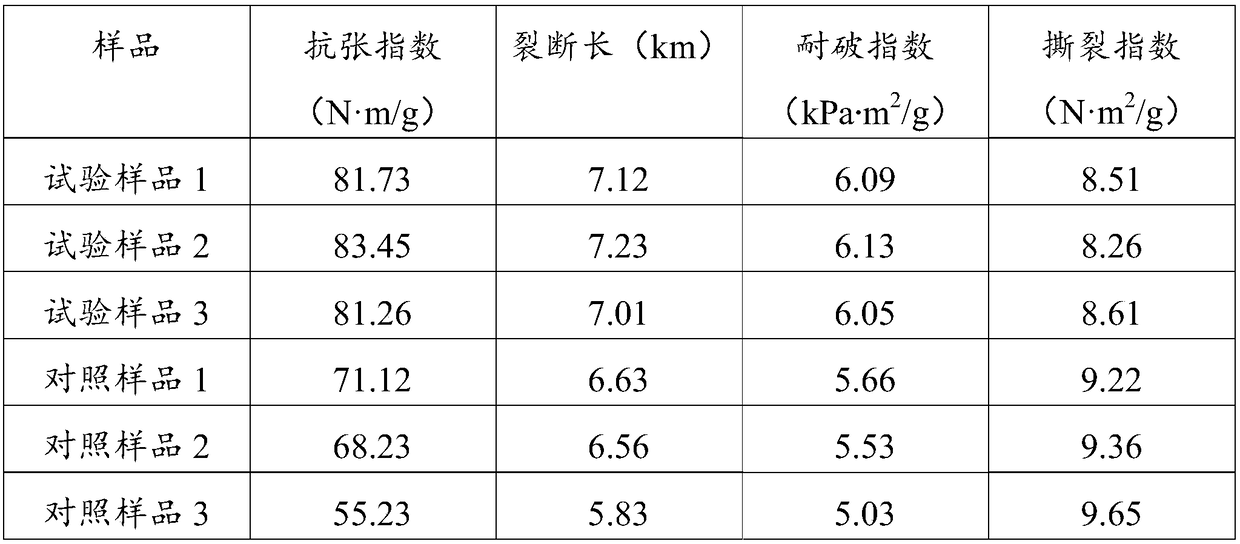

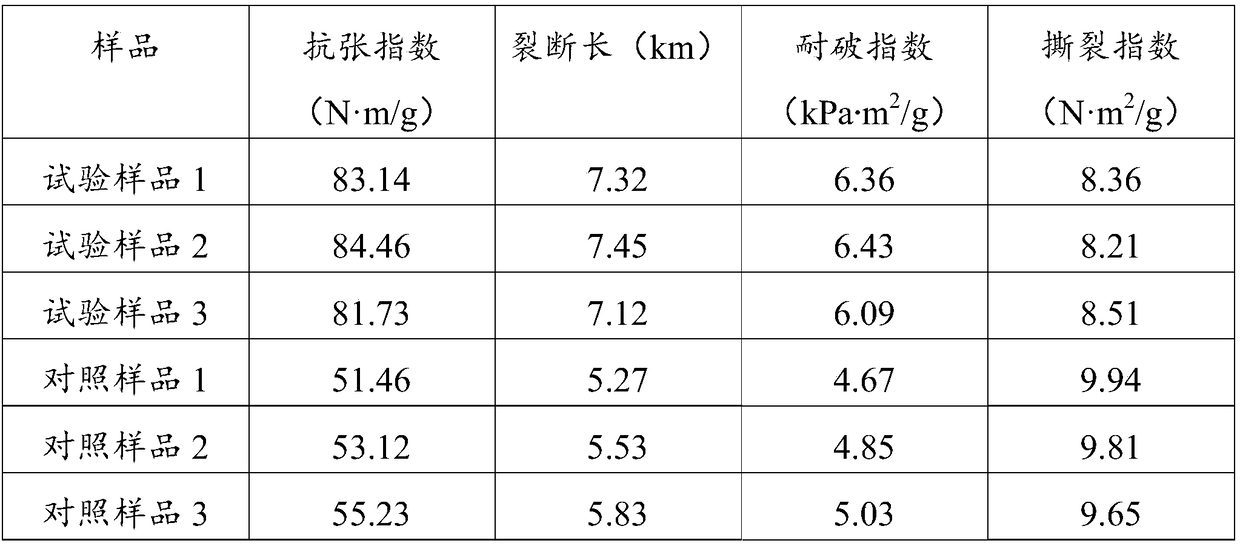

Examples

Embodiment 1

[0030] A kind of method that utilizes composite enzyme to promote the fiber strength of hardwood pulp of the present embodiment, comprises the steps:

[0031] (1) Pretreatment of broadleaf pulp: First, in a hydropulper with a temperature of 35°C and a pH value of 6-8, the stirring rate is 180rpm, and the stirring time is 30min, adding carbohydrate hydrolase and broadleaf pulp board, keeping The temperature is constant, under stirring conditions, the stirring rate is 180rpm, and the stirring time is 30min, and collagenase is added to the broad-leaved pulp to obtain pretreated broad-leaved pulp;

[0032] Wherein, the mass ratio of the carbohydrate hydrolase to the broad-leaved pulp is 1:10000, and the mass ratio of the collagenase to the broad-leaved pulp is 2:10000;

[0033] (2) Add flocculant to the pretreated broadleaf pulp, the mass ratio of flocculant to broadleaf pulp is 2:100, stir evenly, and let stand for 20min;

[0034] (3) Then add a charge regulator, the mass ratio ...

Embodiment 2

[0036] A kind of method that utilizes composite enzyme to promote the fiber strength of hardwood pulp of the present embodiment, comprises the steps:

[0037] (1) Pretreatment of broadleaf pulp: First, in a hydropulper with a temperature of 37°C and a pH value of 6-8, under stirring conditions, the stirring rate is 190rpm, and the stirring time is 45min, adding carbohydrate hydrolase and broadleaf pulp Pulp plate, keeping the temperature constant, under stirring conditions, the stirring rate is 190rpm, and the stirring time is 45min, adding collagenase to the broad-leaved pulp to obtain pretreated broad-leaved pulp;

[0038] Wherein, the mass ratio of the carbohydrate hydrolase to the broad-leaved pulp is 3:2000, and the mass ratio of the collagenase to the broad-leaved pulp is 3:10000;

[0039] (2) Add cationic polyacrylamide flocculant to the pretreated hardwood pulp, the mass ratio of flocculant to broadleaf pulp board is 4:100, stir evenly, and let stand for 30min;

[004...

Embodiment 3

[0042] A kind of method that utilizes composite enzyme to promote the fiber strength of hardwood pulp of the present embodiment, comprises the steps:

[0043] (1) Pretreatment of broad-leaf pulp: First, add β-malt carbohydrate hydrolase and broad-leaf pulp in a hydropulper with a temperature of 40°C and a pH value of 6-8, with a stirring rate of 200 rpm and a stirring time of 60 minutes. plate, keeping the temperature constant, under stirring conditions, the stirring rate is 200rpm, and the stirring time is 60min, adding collagenase to the broad-leaved pulp to obtain pretreated broad-leaved pulp;

[0044] Wherein, the mass ratio of the carbohydrate hydrolase to the broad-leaved pulp is 2:10000, and the mass ratio of the collagenase to the broad-leaved pulp is 4:10000;

[0045] (2) Add polyaluminium chloride flocculant to the pretreated broadleaf pulp, the mass ratio of flocculant to broadleaf pulp board is 7:100, stir evenly, and let stand for 40min;

[0046] (3) Then add a k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com