Position-changeable self-adaptive switch double-passage energy-saving reciprocation oil feeding device

A technology of self-adaptive switching and oil supply device, applied in the direction of charging system, engine components, liquid fuel feeder, etc. Adapt to the problem of adjusting the motion stroke, etc., to achieve the effect of simple and feasible adjustment method, good economic benefits and energy saving effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

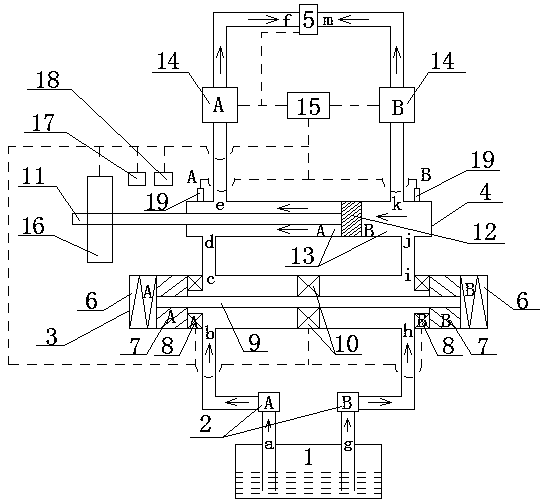

[0019] Embodiment: variable position self-adaptive switching dual-channel energy-saving reciprocating fuel supply device, including fuel supply device and electrical control system, fuel supply device includes fuel tank 1, filter 2, reciprocating fuel supply pump 4 and electronically controlled fuel injector 5; The reciprocating oil supply pump 4 is composed of a piston rod 11, a piston 12 and an oil supply chamber 13. The oil supply chamber 13 is divided into a left oil supply chamber 13A and a right oil supply chamber 13B by the piston 12, and the left oil supply chamber 13A is provided with an oil supply circuit af , the oil supply path gm is set on the right oil supply chamber 13B; the lower end of the reciprocating oil supply pump 4 is provided with a variable position valve 3, the lower end of the variable position valve 3 is connected to the filter 2 and the fuel tank 1 in turn, and the upper end of the reciprocating oil supply pump 4 The switch valve 14 and the electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com