Rapid erection method and device for large-tonnage solid rocket

A solid rocket and large-tonnage technology, applied in the field of hydraulic control, can solve the problems of not meeting the high reliability and safety requirements of the erecting process, low basic reliability of the erecting system, and reduced reliability of the erecting link, etc., to achieve The effect of shortening the erecting time, safely erecting in place, and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

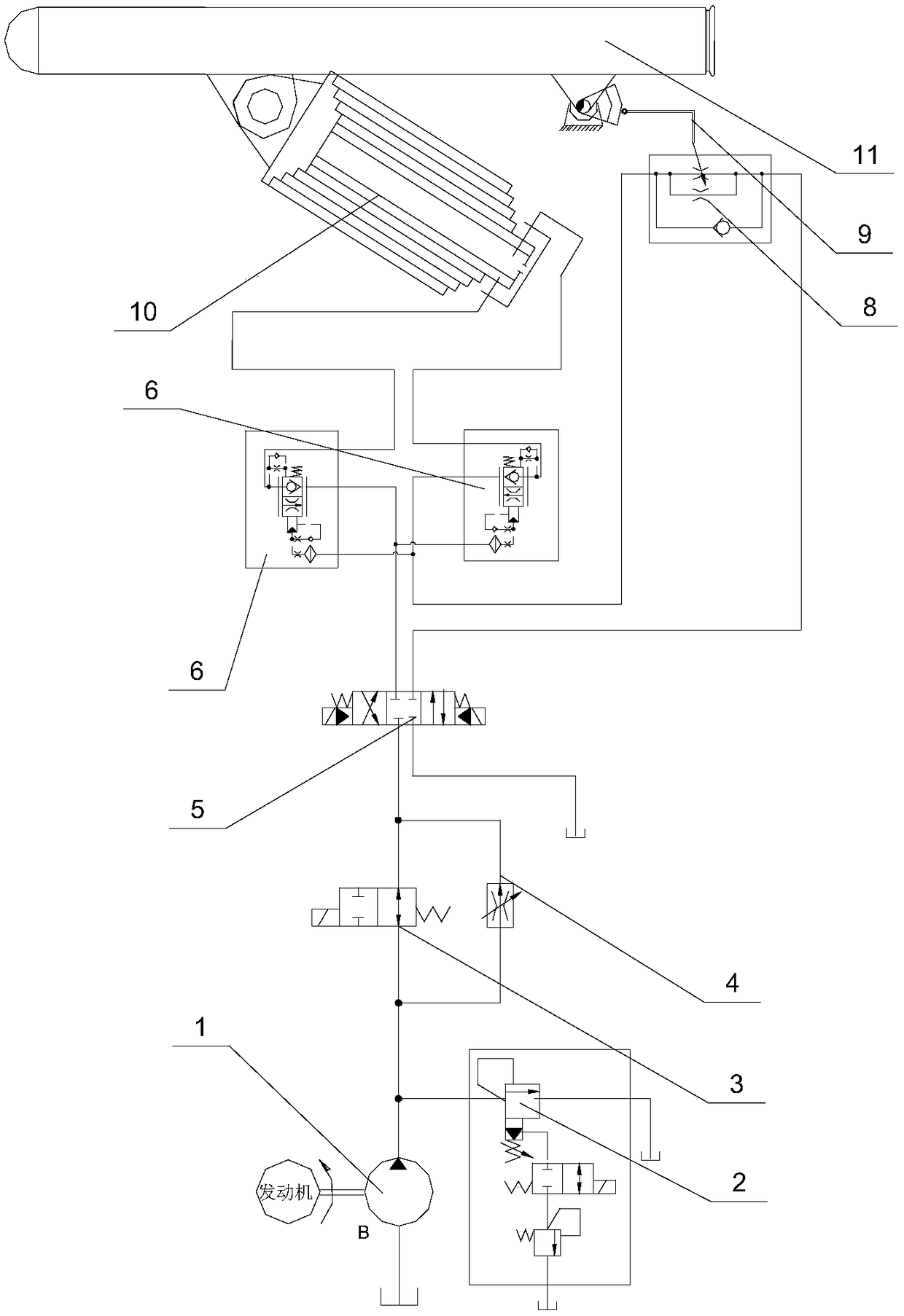

[0029] A kind of large-tonnage solid rocket fast erecting device of the present invention, such as figure 1 shown. The design principle of the present invention is: the erecting process is divided into a fast erecting stage, an erecting deceleration stage and a slow erecting stage.

[0030] a. Quantitative pump 1 is used for erecting oil source, such as gear pump or plunger pump. In the rapid erecting stage, the output flow of quantitative pump 1 directly enters the erecting actuator 10. There is no throttling and speed regulating link in the middle, hydraulic components, The system circuit has simple structure and high reliability; the erecting actuator 10 in the present invention is an erecting hydraulic cylinder;

[0031] b. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com