Device and method for measuring liquid level of optical fiber adjustable in precision on basis of optical chaos

A technology of liquid level measuring device and optical fiber, which is applied in the direction of measuring device, liquid/fluid solid measurement, lubrication indicating device, etc. It can solve the problems of short sensing distance, complicated manufacturing of sensing unit, and inability to meet the measurement task, and achieve high precision Effects of Controlled, Intrinsically Safe Volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

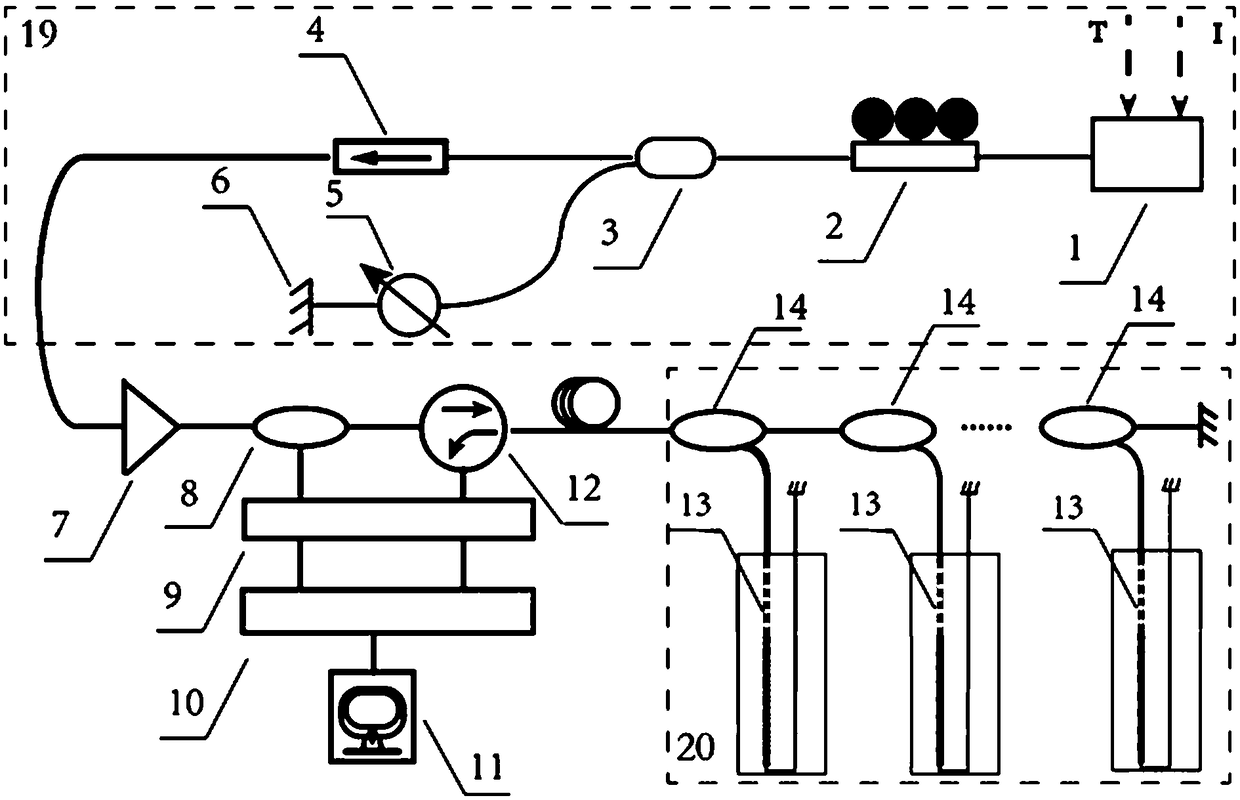

[0031] Specific embodiment one: the present embodiment will describe in detail the chaotic light source module a, the chaotic source module 19 consists of DFB-LD laser 1, bias controller 2, coupler A3, optical isolator 4, optical attenuator 5 and optical fiber Composed of 6 reflectors.

[0032] The laser output from DFB-LD laser 1 is input to the input port a of the coupler A3 through the polarization controller 2, and the output port b of the coupler A3 is connected to the fiber mirror 6 through the optical attenuator 5; the output port c of the coupler A3 is connected to the optical isolator 4 connections. The function of the adjustable optical attenuator 5 is to adjust the optical power of the feedback optical path, that is, the optical power fed back to the DFB-LD laser 1, and the function of the polarization controller 2 is to control the polarization state of the light.

[0033] In addition, the configuration of the chaos source module 19 is not limited to the optical fee...

specific Embodiment approach 2

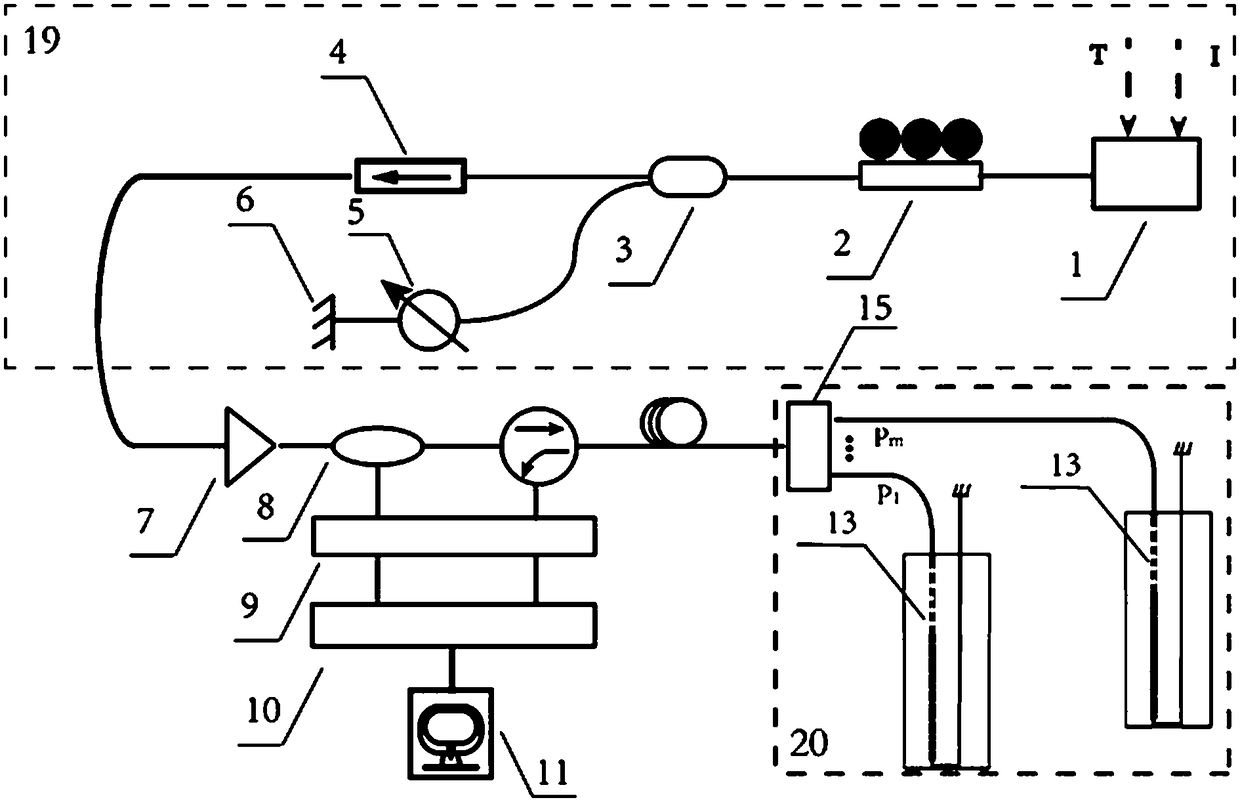

[0034] Specific embodiment two: as shown in reference 1, a fiber optic liquid level sensing device with adjustable precision based on optical chaos, including: a chaotic light source module 19, an optical fiber amplifier 7, a coupler B8, a photoelectric detection module 9, and a cross-correlation operation A unit 10, a computer 11, a circulator 12, a sensing unit 13 and a coupler C14, where there are multiple sensing units 13 and couplers C14.

[0035] The chaotic light generated by the chaotic light source module 19 enters the input port a of the coupler B8 through the optical fiber amplifier 7, the first output port b of the coupler B8 is connected to the input port a of the circulator 12, and the first output port b of the circulator 12 is connected to the sensing fiber. Each node to be tested on the sensing fiber is connected to a coupler C14, the first output port b of each coupler C14 is connected to a sensing unit 13, and the second output port c of the coupler C14 is co...

specific Embodiment approach 3

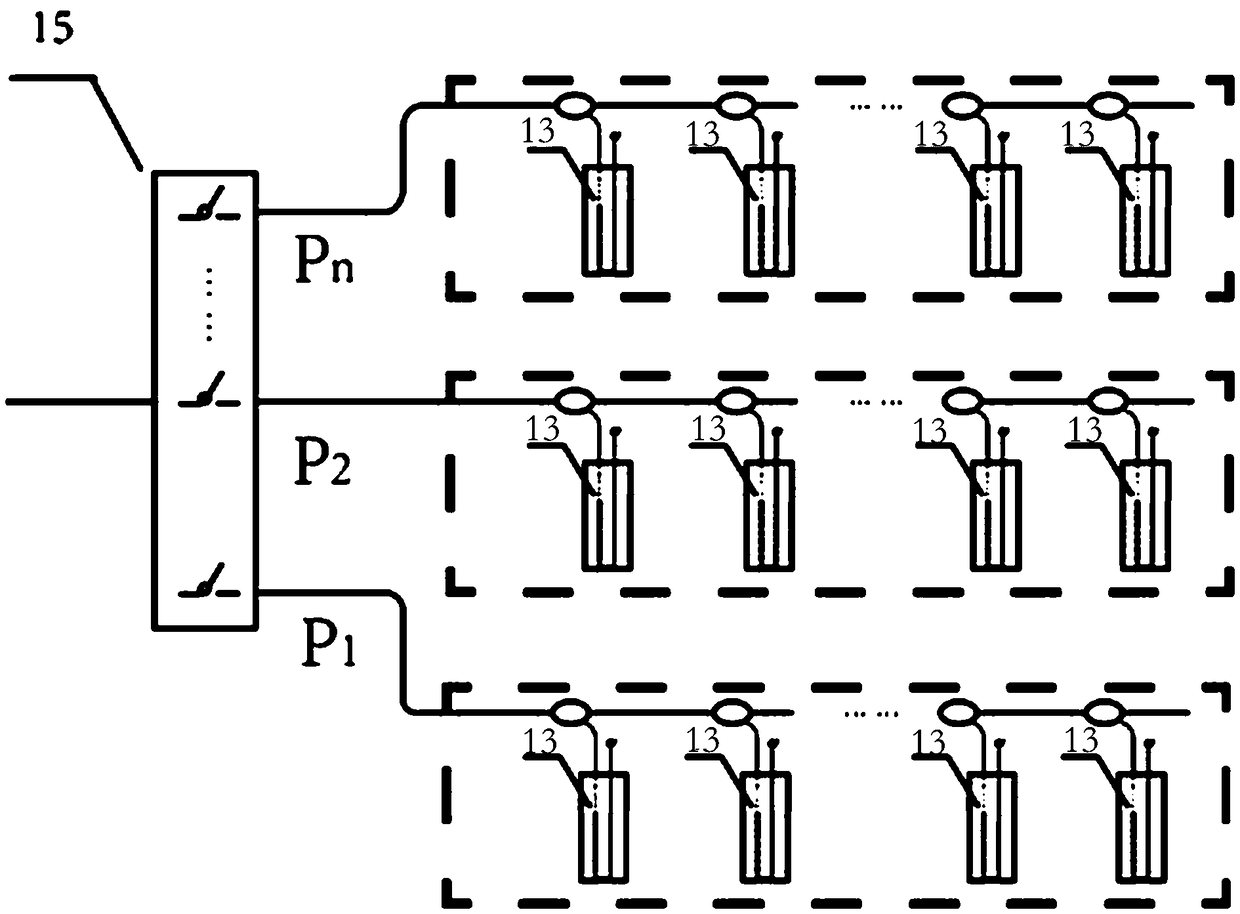

[0036] Specific Embodiment Three: Referring to Figure 2, an optical-chaos-based precision-adjustable optical fiber liquid level sensing device, the topology of the measurement sensor network module 20 may also be a parallel structure. The detection light is output to the multi-channel switch 15 through the first output port of the circulator 12, and each channel is connected to the sensing unit 13 located at a different position, and by controlling the switch states of different channels, the reflected signals of different channels are cross-correlated with the reference signal , to get the liquid level information of each monitoring point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com