Electrochemical working electrode engraved with metal nano grating and preparation method of electrochemical working electrode

A technology of metal nanometer and working electrode, which is applied in the field of electrochemistry, can solve the problems of lack of understanding of electrochemical reactions, difficulty in measuring infrared spectra, etc., and achieve the effect of increasing the strength of the field and compensating for strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

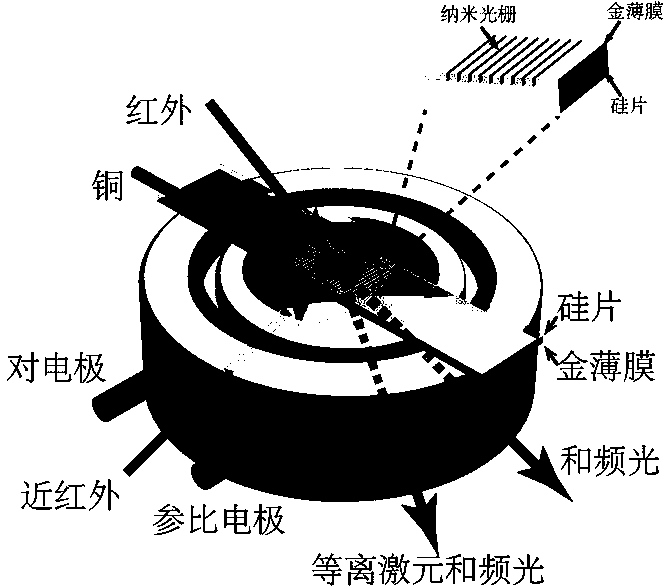

[0020] In the following, an electrochemical working electrode of a metal nano-grating is prepared by using gold as a raw material and a silicon wafer as a substrate as an example. The specific implementation is as follows:

[0021] (1) Use Comsol software to build a model, given an infrared incident angle of 74 degrees, the model is the air layer, the substrate substrate, the gold film, and water from top to bottom, and the simulation calculation is carried out to obtain the stretching vibration of the specified chemical bond The optimal combination of gold film thickness, slit width, and grating period for near-field enhancement in the infrared band is on the order of hundreds of nanometers and microns, respectively;

[0022] (2) Use acetone, ethanol, and water to ultrasonically clean the substrate in sequence, or soak the substrate in concentrated sulfuric acid for a period of time to clean the substrate silicon wafer;

[0023] (3) Depositing a thin film of gold on the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com