Online light fluid FP cavity based on suspended core fibers

A core optical fiber and optical fluid technology, applied in the field of online optical fiber optical fluid micro FP cavity, can solve the limitation of the practical process of online optical fiber optical fluid micro FP cavity, improve the cost of online optical fiber optical fluid micro FP cavity, increase the production Process complexity and other issues, to achieve the effect of low cost, low processing cost and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

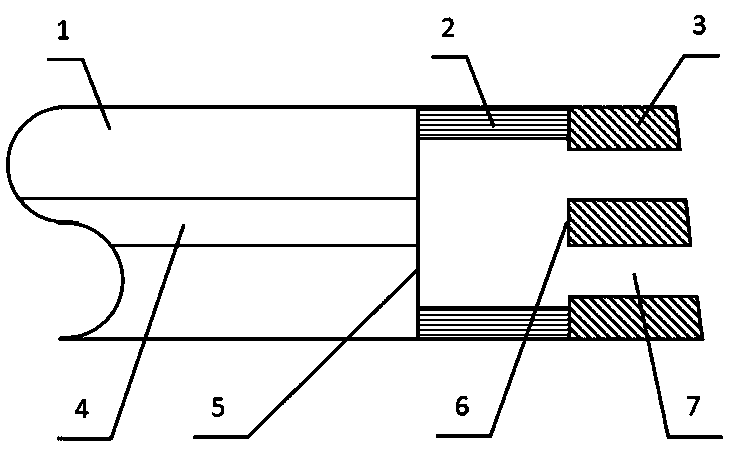

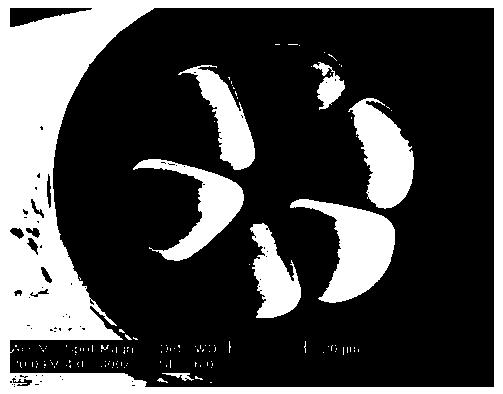

[0018] The present invention proposes an online optofluidic micro-FP cavity based on a suspended core optical fiber, which is composed of a common single-mode optical fiber 1, a quartz capillary 2 and a suspended core optical fiber 3, and its structural diagram is as follows figure 1 As shown; wherein there are 6 large-size air holes in the cladding of the suspended core fiber 3, such as figure 2 As shown, 6 large-sized air holes surround the air hole 7 of the suspended core optical fiber; one end of the common single-mode optical fiber 1 is welded to one end of the quartz capillary 2, wherein the inner diameter of the quartz capillary 2 is greater than the diameter of the core 4 of the common single-mode optical fiber; the quartz capillary The other end of 2 is welded to one end of the suspension-core optical fiber 3, wherein the inner diameter of the quartz capillary 2 is greater than the outer diameter of the air hole of the suspension-core optical fiber 3; the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com