Curing thermal process spatial-temporal modeling method based on ISOMAP

A modeling method and curing heat technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems that model parameters cannot be obtained, accurate partial differential equation description of the curing process is difficult to obtain, and boundary conditions are complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

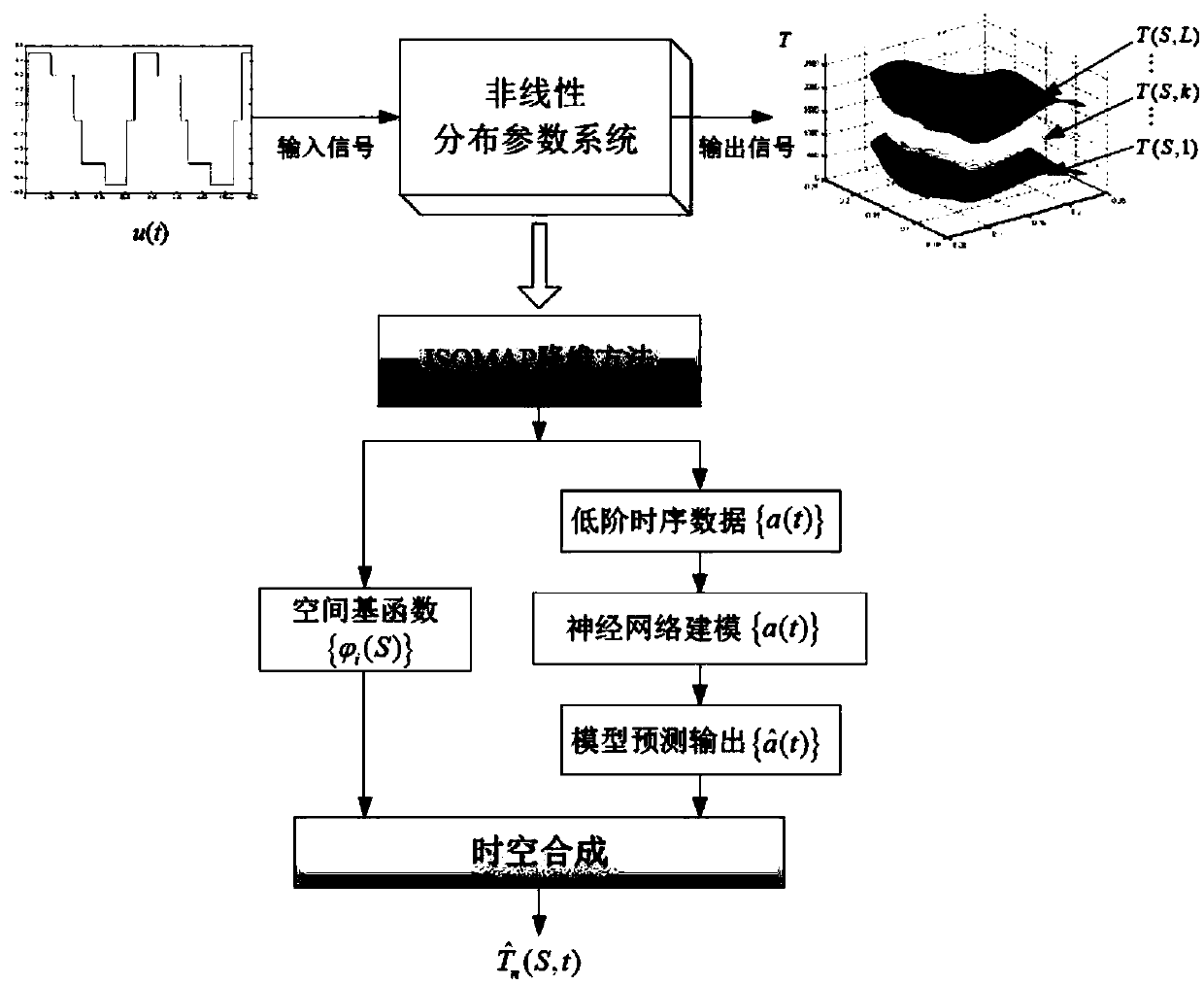

[0054] The ISOMAP-based spatio-temporal modeling method of curing thermal process of the present embodiment:

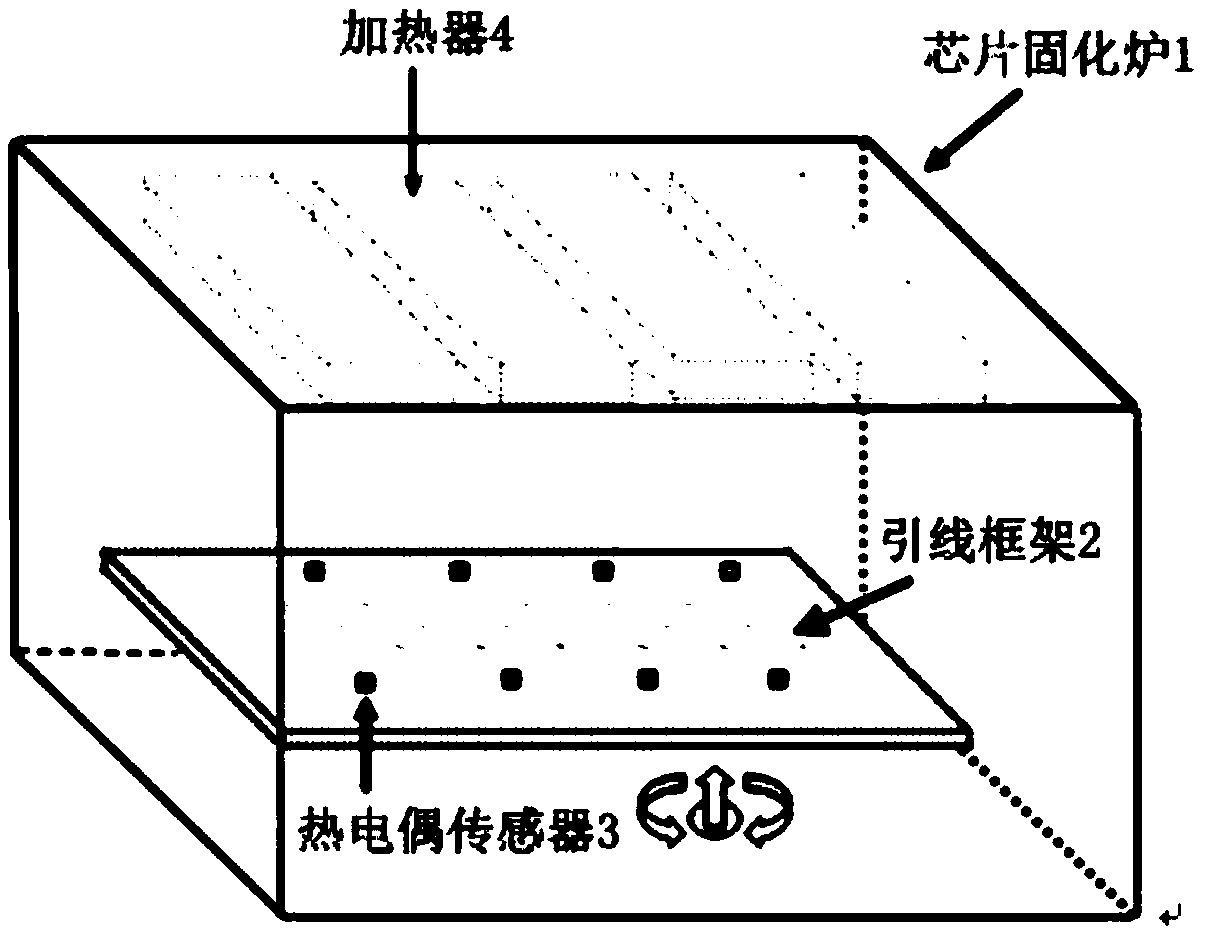

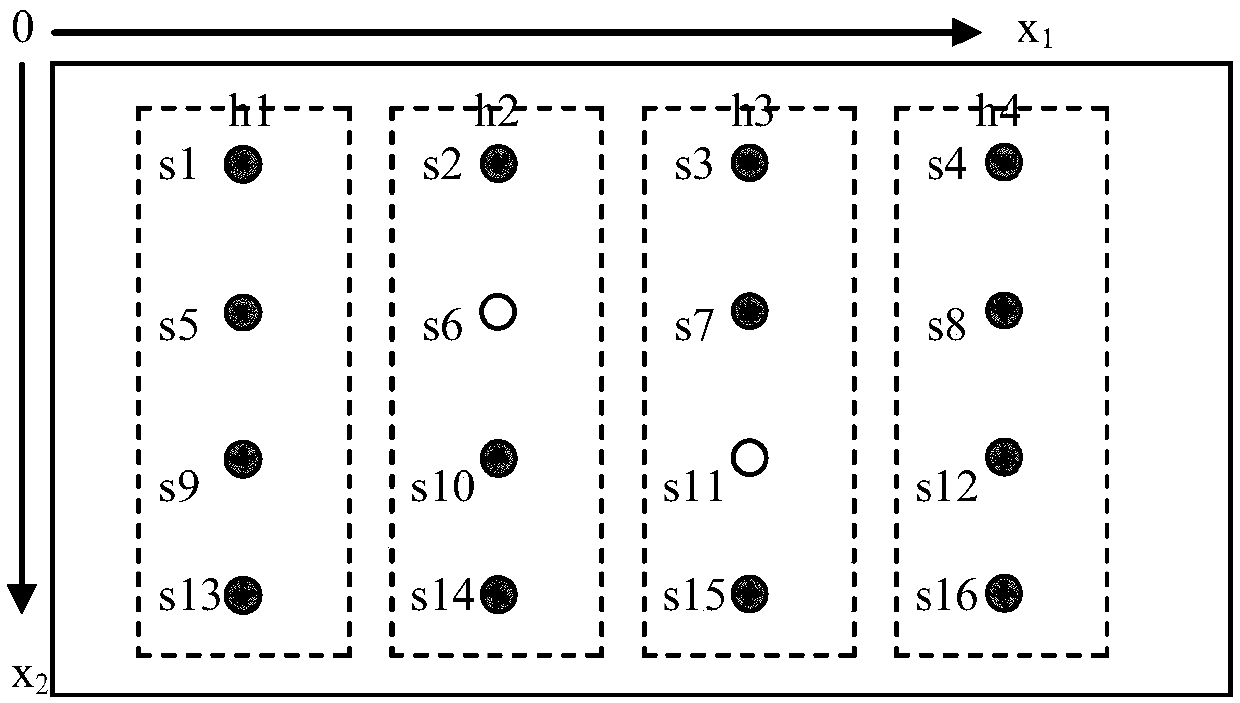

[0055] Step 1: Build a chip curing furnace temperature control platform, such as figure 1 , figure 2 As shown, a lead frame 2 is installed at the bottom of the furnace cavity of the chip curing furnace 1, and a plurality of thermocouple sensors 3 are evenly arranged on the upper surface of the lead frame 2, and the temperature data of all thermocouple sensors 3 are collected by the dSPACE real-time simulation platform, and the A plurality of heaters 4 are evenly arranged above the lead frame 2, and each heater 4 is provided with an input signal by a pulse width modulation signal and a power amplifier Make the chip curing furnace 1 perform curing work;

[0056] Step 2, the dSPACE real-time simulation platform counts the temperature data of all thermocouple sensors 3, and obtains the time-space data of the temperature distribution of the chip curing furnace 1 under ...

Embodiment 2

[0176] This example validates the proposed modeling method by conducting real-time experiments. First, build a chip curing furnace temperature control platform, such as figure 1 As shown, a lead frame 2 is installed at the bottom of the furnace chamber of the chip curing furnace 1, and 16 thermocouple sensors 3 of the same specification are evenly arranged on the upper surface of the lead frame 2. The detailed arrangement position of the thermocouple sensors 3 is as follows figure 2 shown. Four heaters 4 of the same specification are evenly arranged above the lead frame 2 , and the power of each heater 4 is 700w. The thermocouple sensors 3 are evenly arranged on the same horizontal plane 5 mm below the heater 4 . Each heater 4 is supplied with an input signal by a PWM signal and a power amplifier Make the chip curing furnace 1 perform curing work; the control input signal of the second heater h2 Such as Figure 5 shown. The temperature data of all thermocouple sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com