Foundation composition and preparation method thereof

A technology of composition and foundation, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of high energy consumption and time cost, complicated preparation process, long emulsification time, etc., to improve film forming speed, Reduces makeup breakout, light skin feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

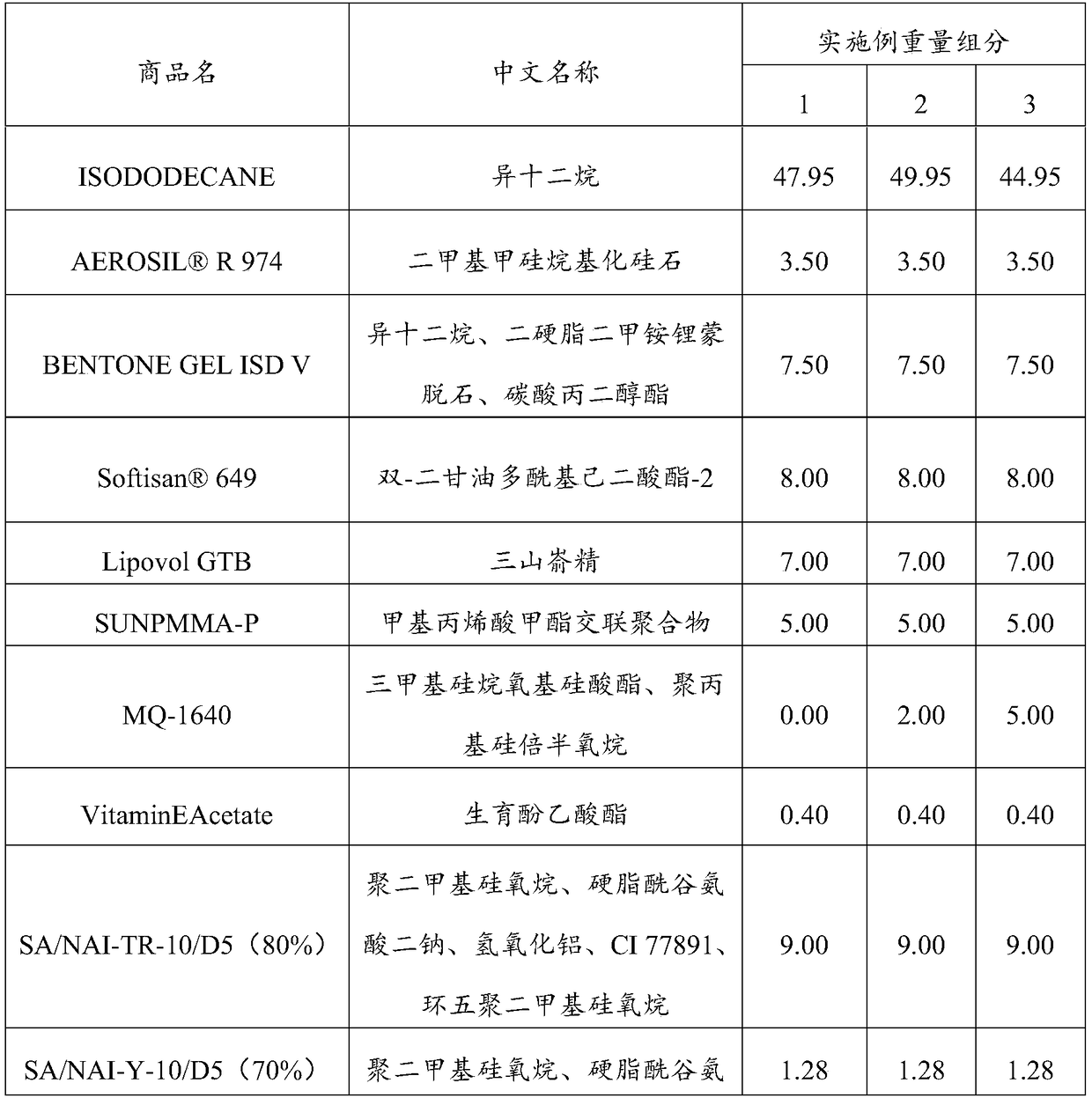

[0053] The present embodiment provides a kind of preparation method of foundation composition, described method comprises the following steps:

[0054] (1) heating and melting bis-diglycerol polyacyl adipate-2, tribehenin, trimethylsiloxysilicate, polypropylsilsesquioxane, tocopheryl acetate and colorant, Homogeneous after stirring, the coloring agent is composed of polydimethylsiloxane, disodium stearyl glutamate, aluminum hydroxide, titanium dioxide, CI77492, CI77491, CI77499 and cyclopentasiloxane mixture;

[0055] (2) Stir and heat the mixture obtained in step (1) to 65° C., add methyl methacrylate crosslinked polymer, stir evenly, and keep warm at 65° C. for later use;

[0056] (3) adding isododecane to homogeneously stir and disperse the dimethylsilyl silicate, then add distearyldimethylammonium hectorite and propylene carbonate, and homogeneously disperse to obtain a suspension dispersion slurry;

[0057] (4) Add the suspension dispersion slurry and oat kernel oil obt...

Embodiment 5

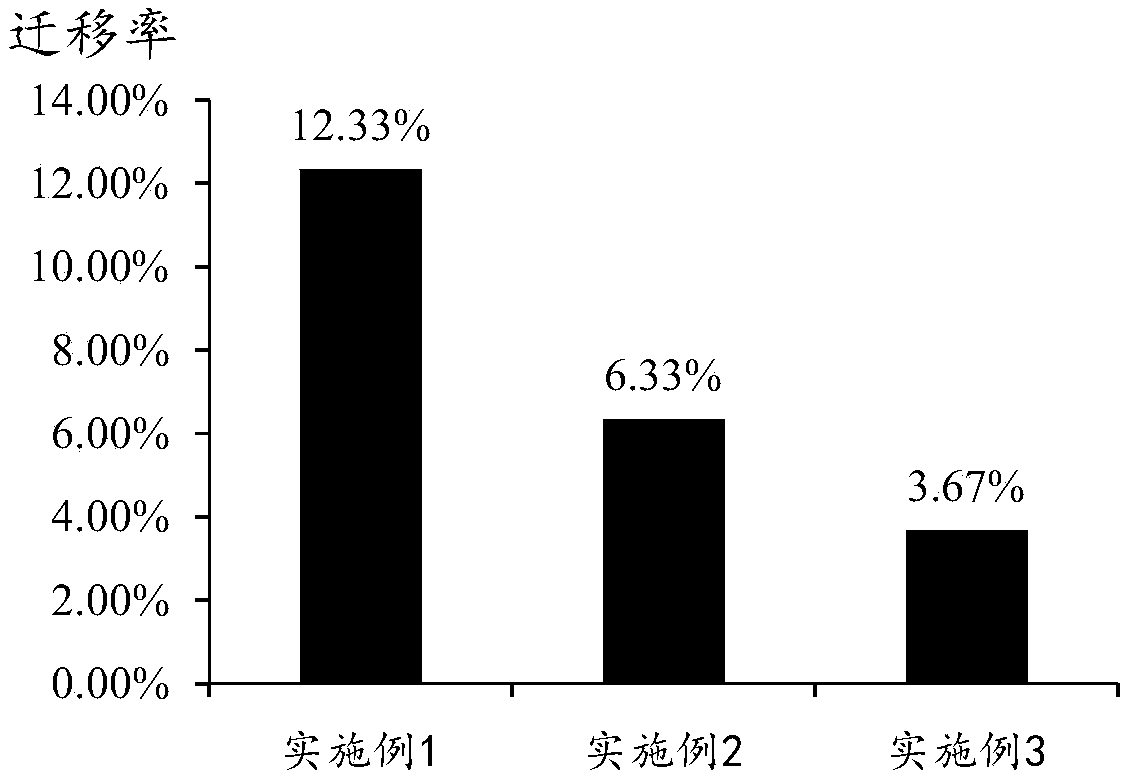

[0059] The migration and water resistance of the foundation compositions of Examples 1-3 were tested.

[0060] 1. Migration performance test

[0061] Use a dropper to take 0.30 g of the foundation composition of Examples 1-3 and drop it on the forearm, spread it evenly with a spoon with a smooth surface, and let it stand for 5 minutes to dry naturally. Use paper towels to press the three areas with the same strength, and use an analytical balance to weigh the weight increment (that is, the amount of foundation migration) of the three paper towels. The experimental results are shown in Table 2:

[0062] Table 2 Mobility of foundation compositions of Examples 1-3.

[0063]

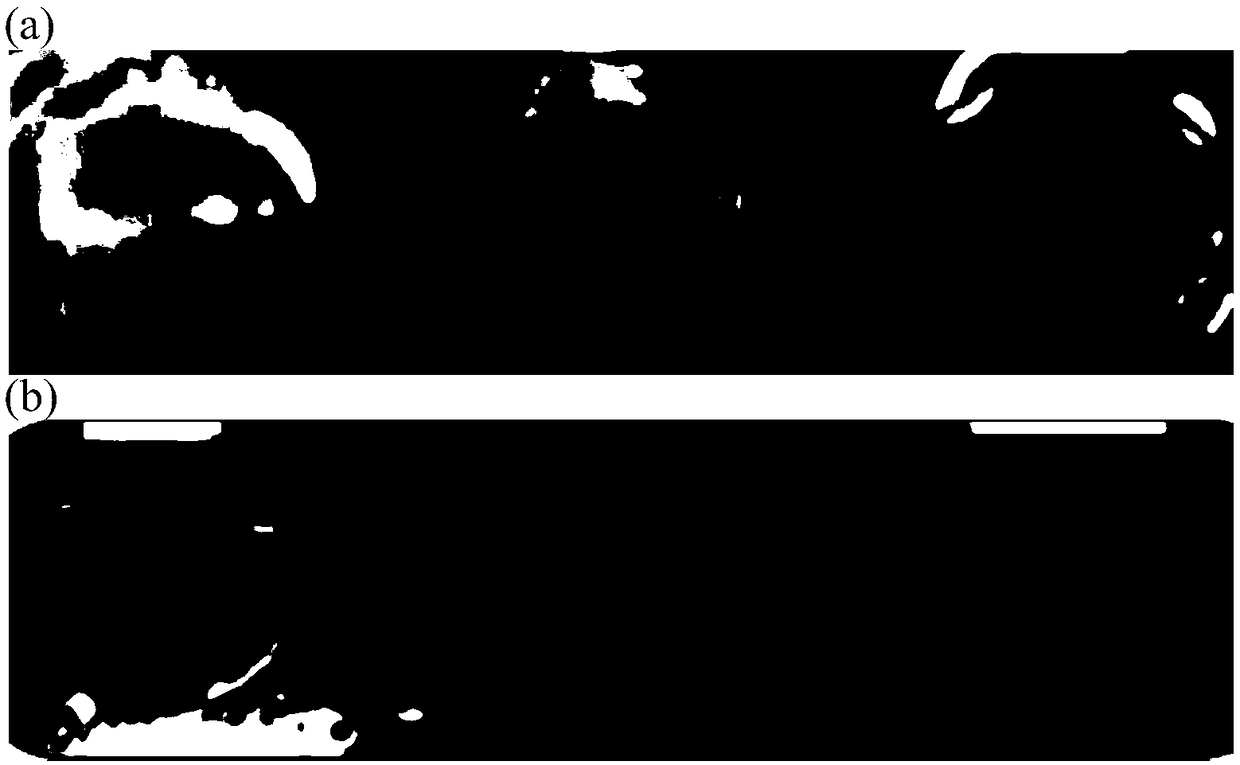

[0064] 2. Water resistance test

[0065] Use a dropper to take 0.30 g of the foundation compositions of Example 1, Example 2, and Example 3 on the color chart, spread evenly, and let it stand for 5 minutes to dry naturally. Rinse with tap water for 10 seconds at the same flow rate.

[0066] Exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com