Water-in-oil cream containing natural source emulsifier and preparation method thereof

A technology of natural origin and emulsifier, applied in the field of skin care products, can solve the problems of high requirements on formulation, equipment and process, greasy and heavy skin feeling, and difficulty in mass production, and achieves easy mass production, non-greasy skin feeling, The effect of reducing energy consumption in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

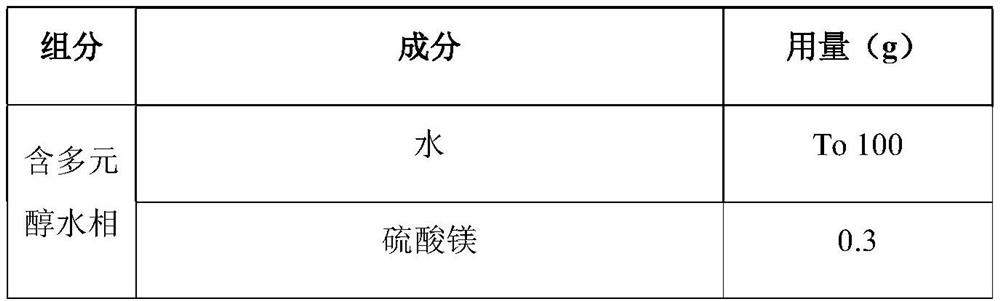

[0030] Embodiment 1: A kind of water-in-oil infant buttock protective milk and its preparation method

[0031]

[0032]

[0033] Step 1, completely dissolving the aqueous phase containing polyhydric alcohol;

[0034] Step 2. First use caprylic acid / capric acid triglyceride to homogeneously disperse the zinc oxide in the oil phase, then add other oil phase mixture, homogeneously disperse, then add emulsifier phase mixed phase, stir homogeneously for 10min, Mass speed is 2000r / min;

[0035] Step 3: Add the polyol-containing water phase into the mixed oil phase at one time, stir for 40 minutes, then add lavender essential oil, and continue stirring for 20 minutes to obtain the water-in-oil baby buttock protector.

[0036] The final product is a milky white emulsion. After being inspected at -8°C for one month, and after being cycled at -8°C to 45°C for one month, the product does not delaminate, does not leak water, does not leak oil, and has no obvious difference from the...

Embodiment 2

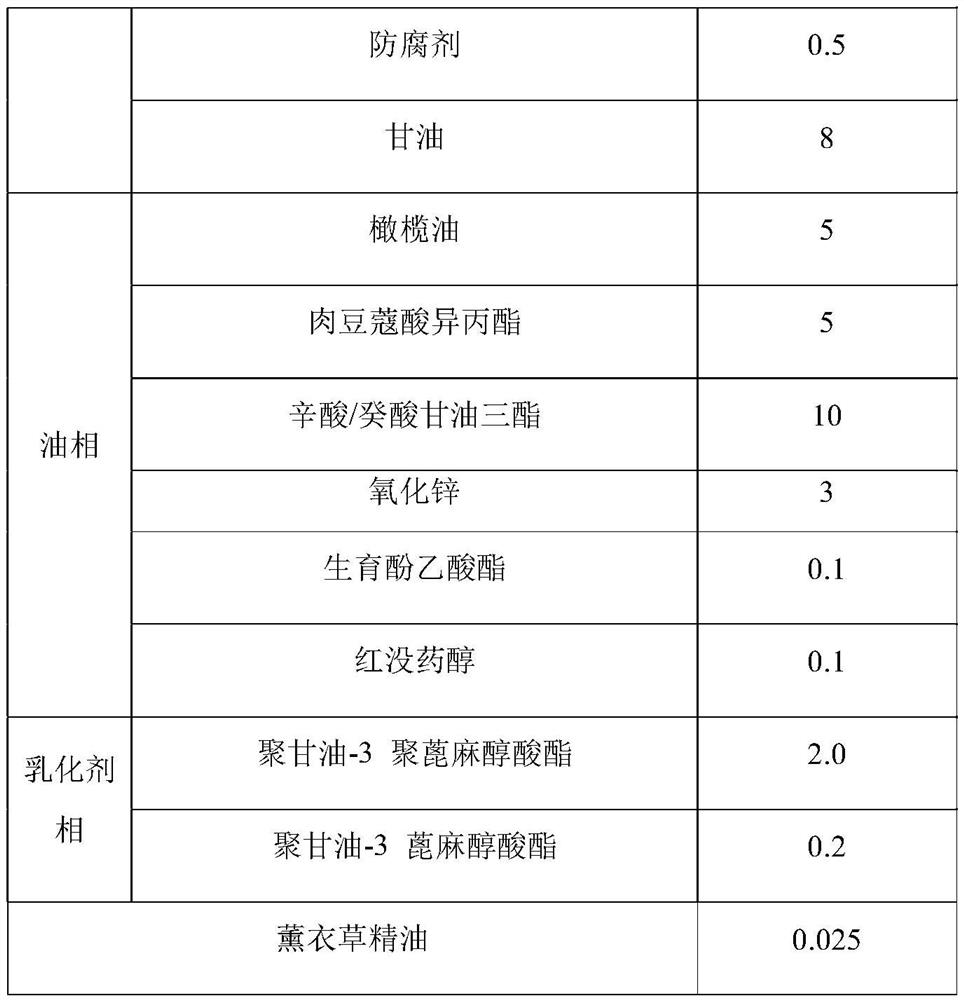

[0037] Embodiment 2: A kind of water-in-oil sunscreen and its preparation method

[0038]

[0039] Step 1. Disperse phenylbenzimidazole sulfonic acid in the polyol-containing water phase with deionized water, then add aminomethylpropanol to make it transparent, and then add other raw materials in the polyol-containing water phase to dissolve completely;

[0040] Step 2. Homogeneously disperse zinc oxide with caprylic / capric triglyceride and C12-15 alcohol benzoate to obtain a dispersed phase of zinc oxide for use; premix other raw materials in the oil phase except zinc oxide and Add the emulsifier phase to homogeneous stirring to dissolve completely, then add the dispersed zinc oxide dispersed phase, homogeneously stir evenly, and the homogenizing speed is 1500r / min;

[0041] Step 3. Add the polyol-containing water phase to the mixed oil phase, stir homogeneously for 30 minutes, then add essence, and stir homogeneously for 5-10 minutes to obtain water-in-oil sunscreen. The ...

Embodiment 3

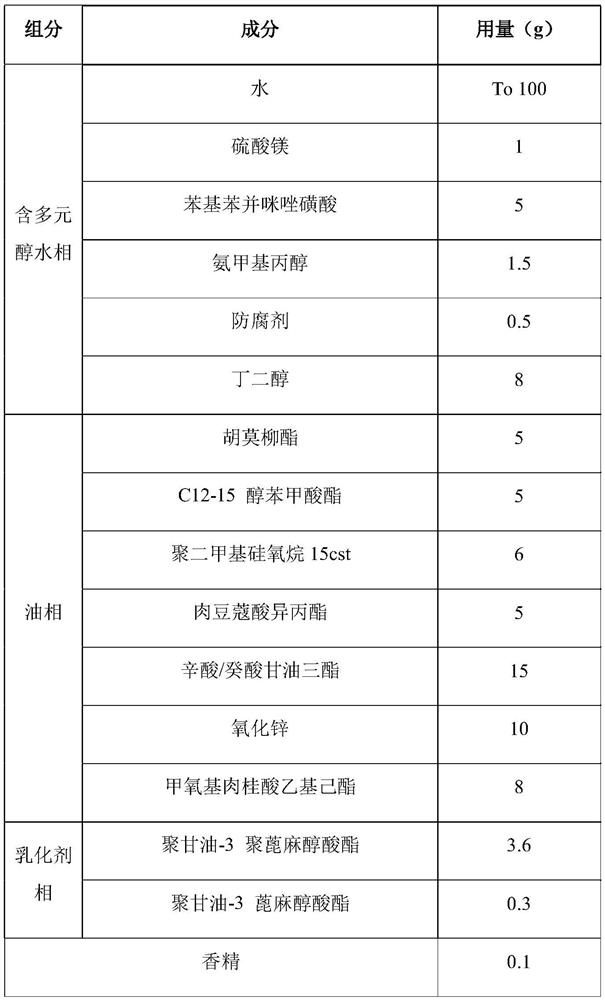

[0043] Embodiment 3: A kind of water-in-oil body lotion and preparation method thereof

[0044]

[0045]

[0046] Step 1, completely dissolving the aqueous phase containing polyhydric alcohol;

[0047] Step 2. Stir and mix the oil phase and the emulsifier phase evenly;

[0048] Step 3: Add the polyol-containing water phase to the mixed oil phase at one time, stir for 40 minutes, then add the essence, and stir homogeneously (1500r / min) for 6 minutes to obtain the water-in-oil body lotion.

[0049] The final product is a milky white emulsion. It has been inspected at -8°C for one month, and after a cycle of -8°C to 45°C for one month, the product has no water or oil leakage, and there is no obvious difference from the constant temperature sample at 6°C; after three months of high-temperature stability inspection at 45°C There is no stratification phenomenon for one month; after 2000r / min, 30min centrifugation inspection also does not stratify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com