Method for realizing deep decarbonization and denitrification through treating sludge digested fluid of municipal sewage plant by adopting semi-short-range nitrification-anaerobic ammonium oxidation-electrooxidation

A technology of anaerobic ammonia oxidation and semi-short-range nitrification is applied in the field of advanced treatment of sludge digestion liquid, which can solve the problem of high carbon source cost and achieve the effect of reducing treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0038] Combined example: the experimental water is taken from the untreated sludge digestion solution of a sewage treatment plant in Beijing, and its water quality is as follows: CODcr is 2800-3000mg L -1 , NH 4 + -N is 2000-2500mg·L -1 , NO x - -N is 0.1-5mg·L -1 , TN is 2900-3100mg·L -1 , TP is 20-40mg·L -1 .

[0039] Routine water quality indicators are determined by national standard methods. TN and TOC etc. adopt TN / TOC analyzer (Multi N / C3000, Jena, Germany).

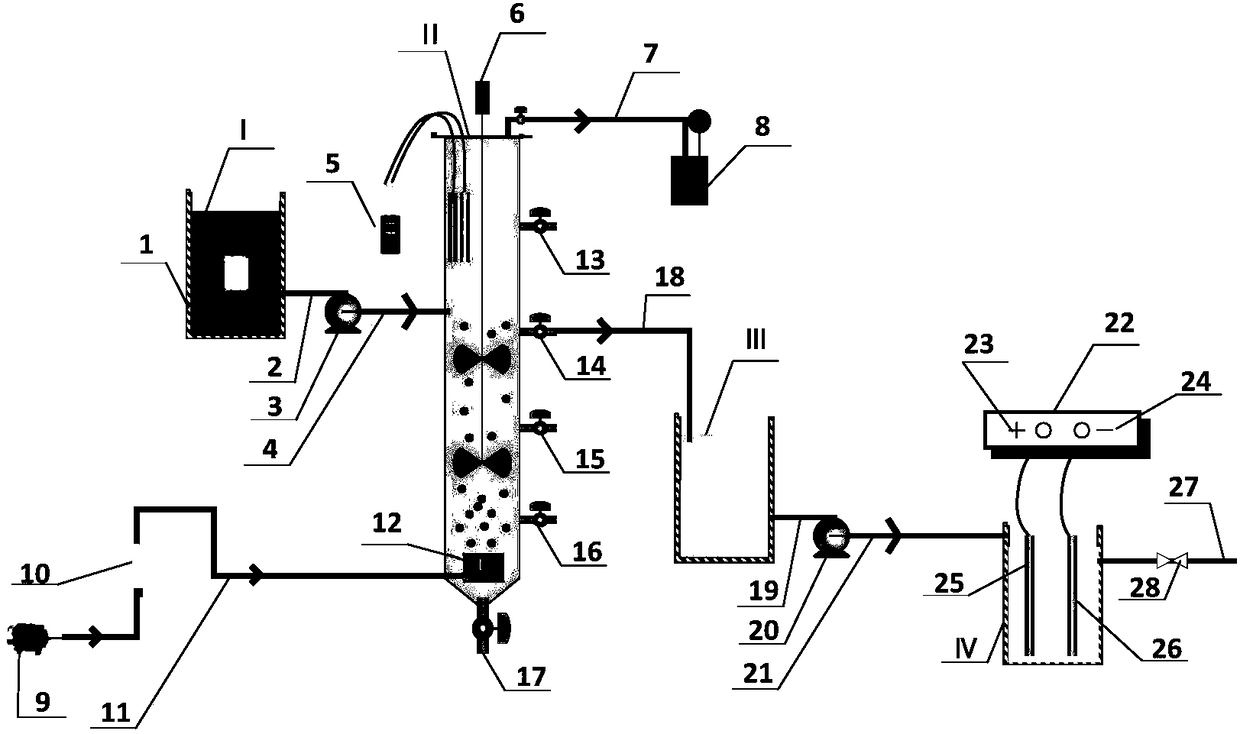

[0040] like figure 1 Shown, the concrete steps that the present invention handles sludge digestate separately are as follows:

[0041] 1) The sludge digestion liquid passes through the outlet pipe (2) from the inlet water tank (Ⅰ) compartment (1), and is pumped into the SBR (Ⅱ) inlet pump (3) and SBR (Ⅱ) inlet pipe (4) In the SBR (II), the volume of the incoming water is 10%-50% of the effective volume of the SBR (II), and each operation cycle of the SBR (II) is: the raw water passes from the inlet comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com