Heavy metal chemical leaching waste liquid processing device and using method thereof

A technology of waste liquid treatment and chemical rinsing, which is applied in the direction of chemical instruments and methods, filtration treatment, separation methods, etc., can solve the problems of waste gas easily polluting the environment, manpower and material resources consumption, and low work efficiency, so as to avoid polluting rivers, avoiding The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

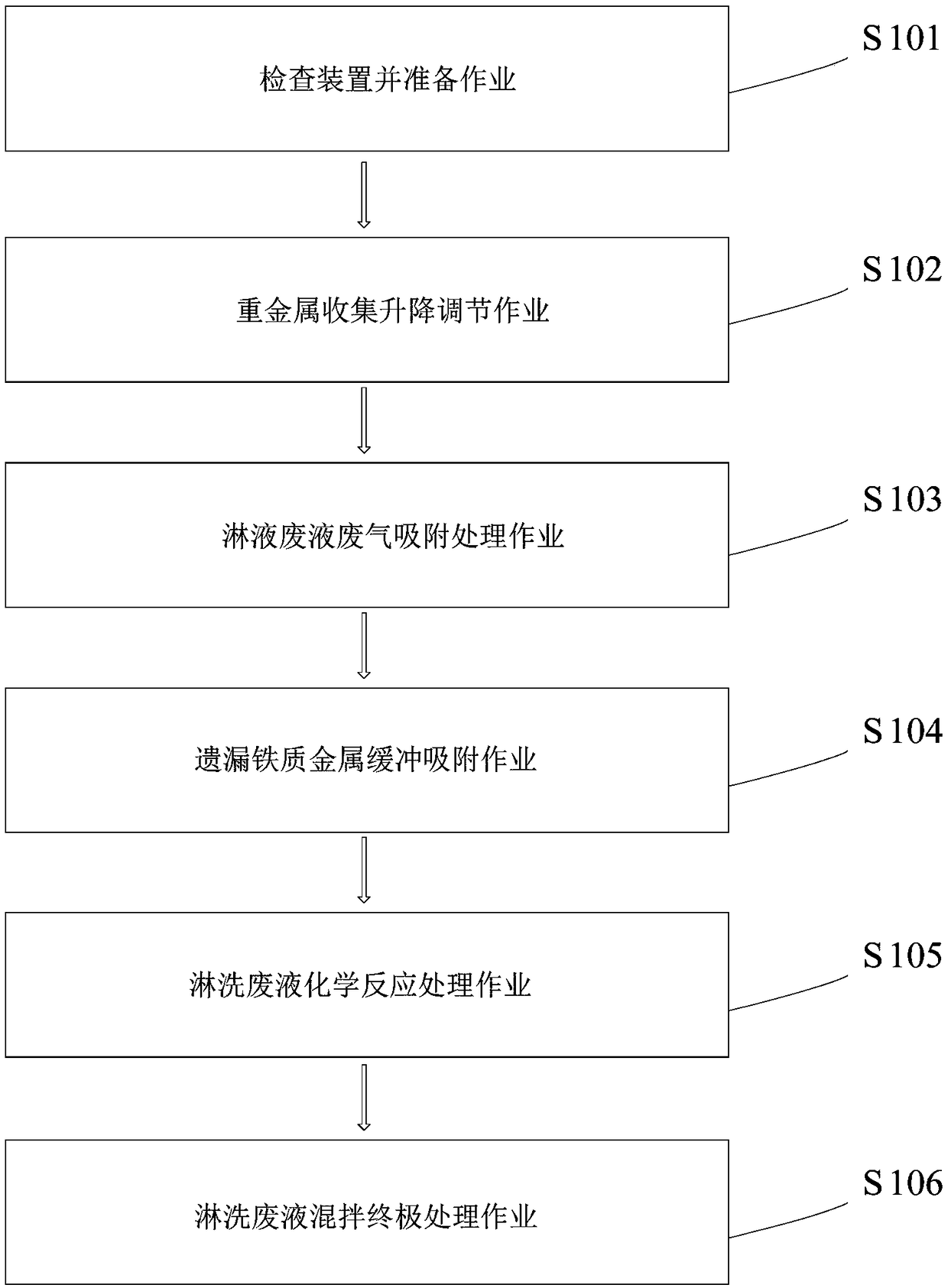

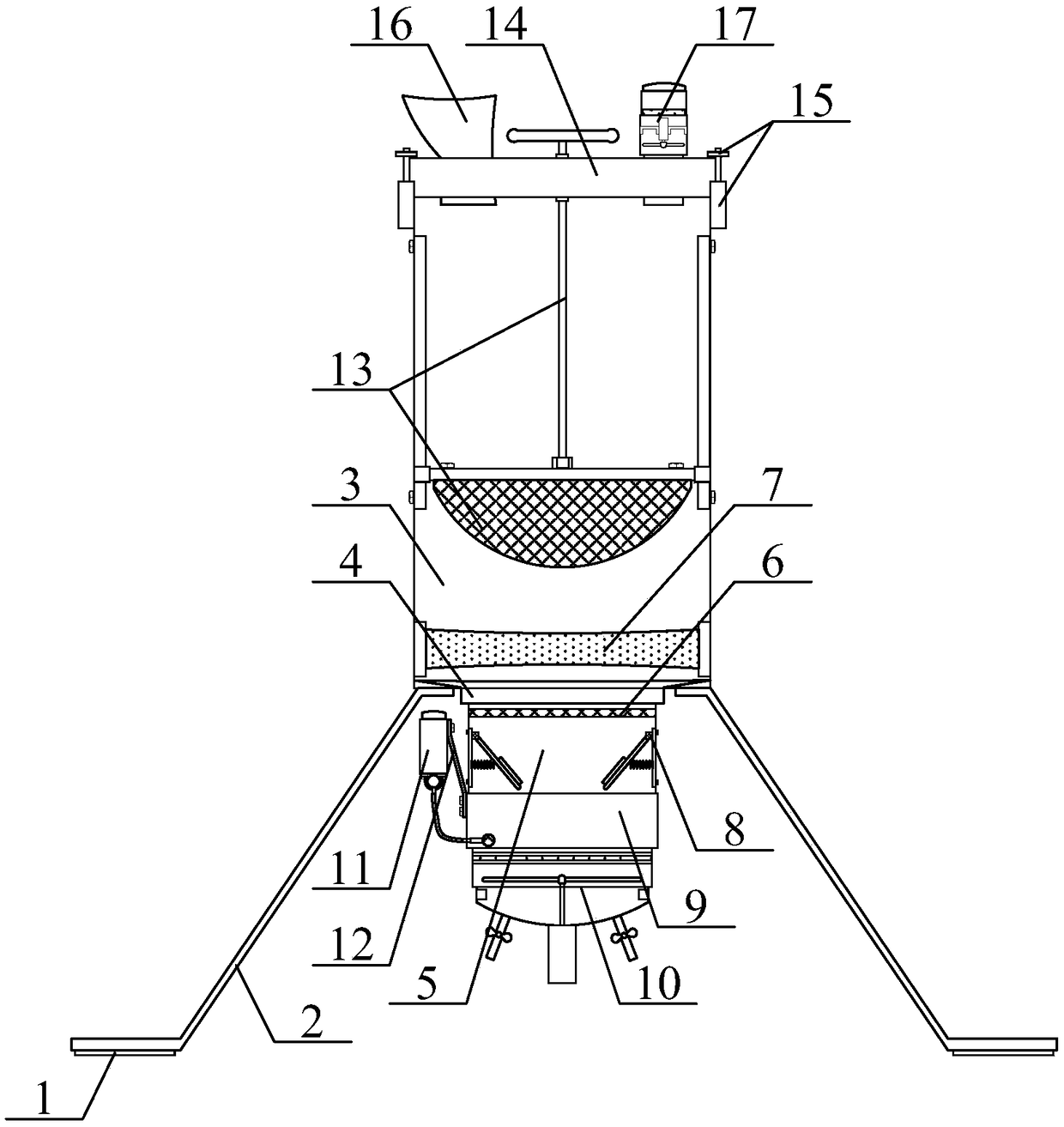

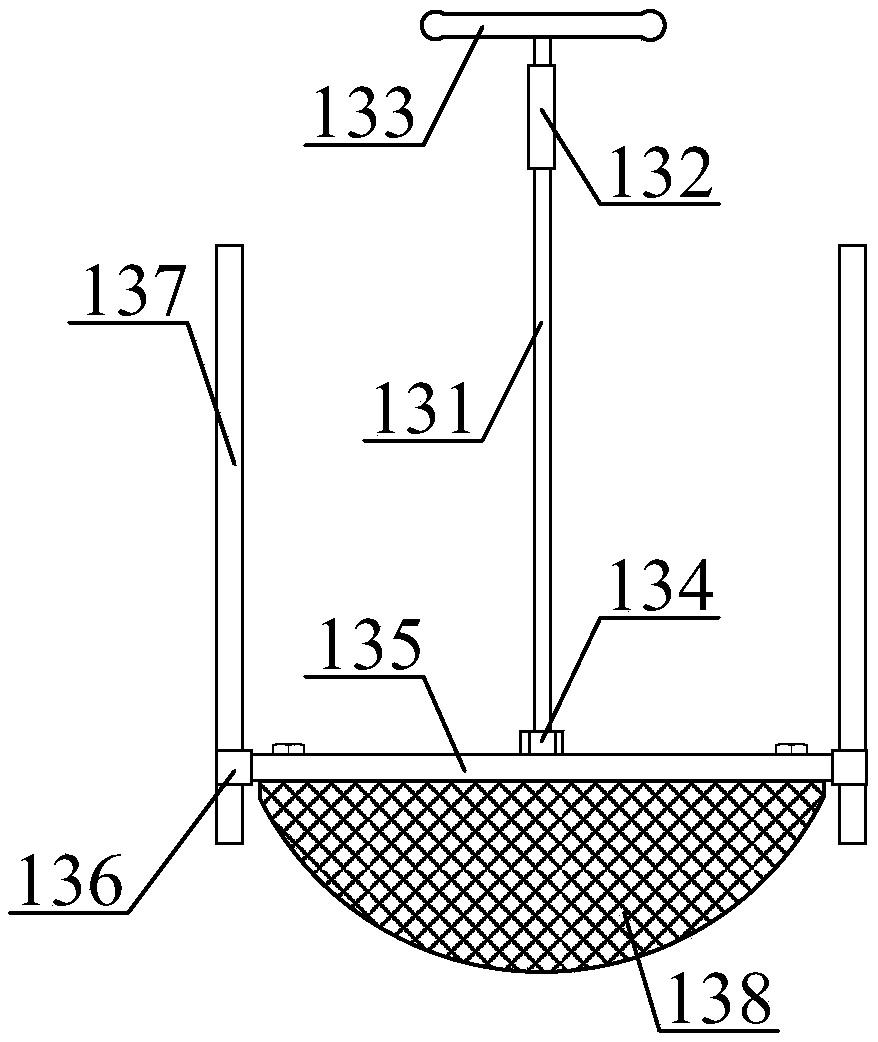

[0060] The present invention will be further described below in conjunction with accompanying drawing:

[0061] In the picture:

[0062] as attached figure 2 to attach Figure 7 shown

[0063]A heavy metal chemical leaching waste liquid treatment device, comprising an anti-slip mat 1, support legs 2, a leaching waste liquid treatment box 3, a leaching waste liquid guide bucket 4, a leaching waste liquid treatment cylinder 5, and a leaching waste liquid cleaning net 6. Inorganic ceramic membrane filter 7, buffer heavy metal iron metal adsorption block structure 8, leaching waste liquid chemical treatment cylinder 9, leaching waste liquid mixed treatment cylinder structure 10, chemical treatment agent adding pump structure 11, support plate 12 , heavy metal salvage filter condition net bag structure 13, cleaning cover 14, quick lock 15, rinsing waste liquid introduction bucket 16 and exhaust gas treatment exporter 17, and the anti-skid pad 1 is laterally glued on the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com