Method and system for separating n-hexane and methylcyclopentane

A technology of methylcyclopentane and n-hexane, applied in the field of organic matter purification, can solve the problems of high reflux ratio, number of plates, limited selectivity, etc., and achieve effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

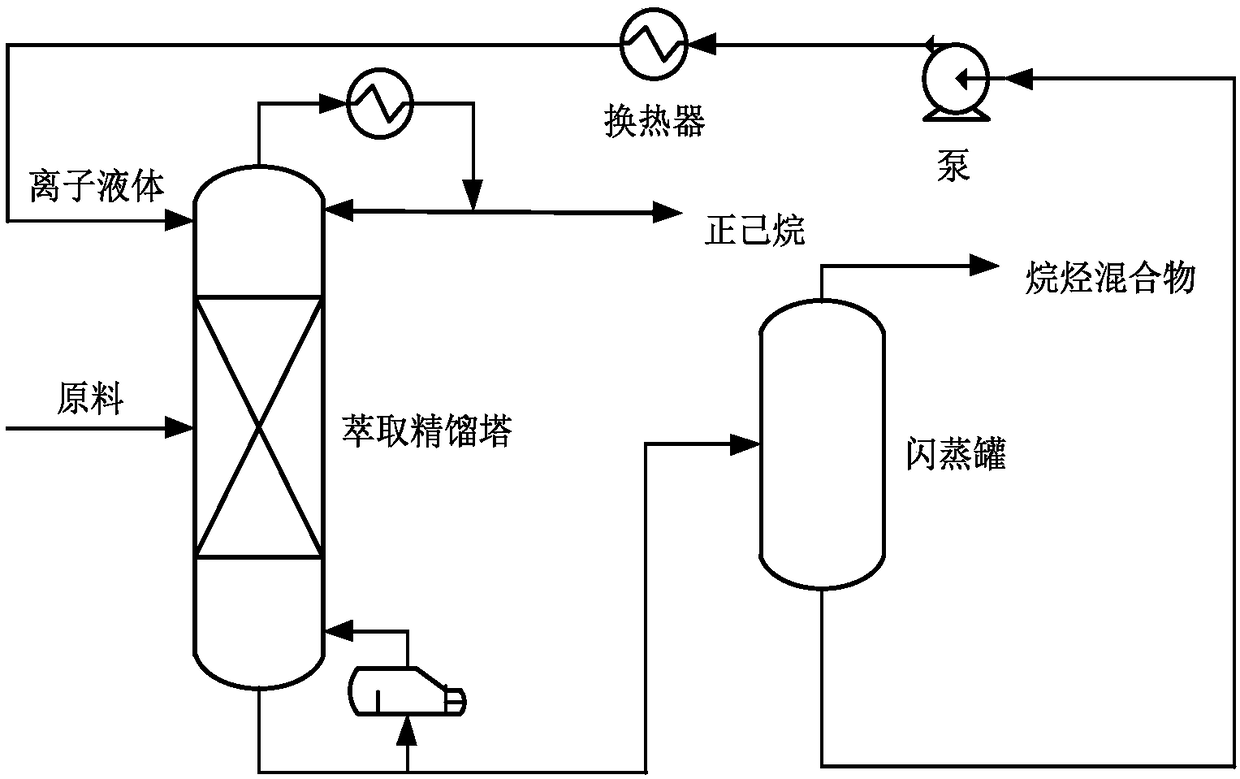

[0065] In this experiment example, the figure 1 The system of the shown separation normal hexane and methylcyclopentane, concrete flow process is as follows:

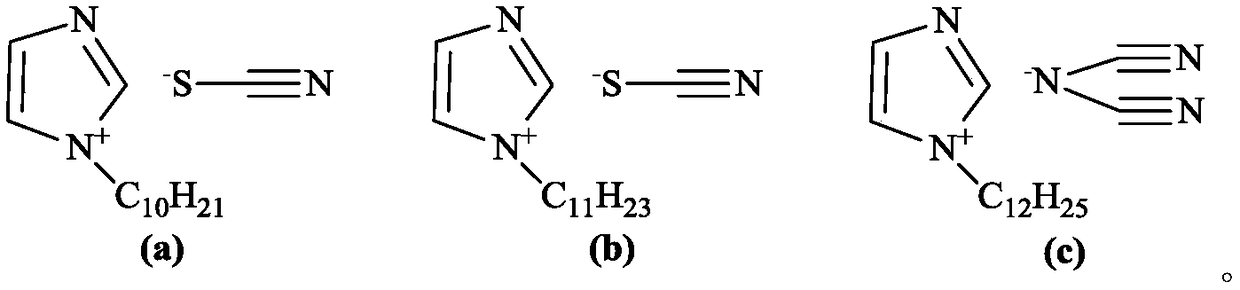

[0066] The actual number of plates in the extractive distillation column is 45, the operating pressure is normal pressure, the operating reflux ratio is 3.6, the temperature at the top of the tower is controlled at 68-69°C, the temperature at the bottom of the tower is 113-114°C, and the ionic liquid at 25°C [C 10 Im] [SCN] enters by tower top, and the massfraction of 25 ℃ is that the near boiling mixture of the n-hexane-25% of 75% methylcyclopentane enters with the flow rate of 100kg / h by the 30th plate, controls ionic liquid and The mass ratio of the raw materials is 1:5, the steam rising from the top of the tower is condensed by the top condenser, and the reflux liquid is refluxed from the top of the tower. The output of the top of the tower is 715kg / h, and the n-hexane product with a mass fraction of 99.07% is obtai...

Embodiment 2

[0068] In this experiment example, the figure 1 The system of the shown separation normal hexane and methylcyclopentane, concrete flow process is as follows:

[0069] The actual number of plates in the extractive distillation column is 45, the operating pressure is normal pressure, the operating reflux ratio is 3.6, the temperature at the top of the tower is controlled at 68-69°C, the temperature at the bottom of the tower is 124-125°C, and the ionic liquid at 25°C [C 10 Im] [SCN] enters by tower top, and the massfraction of 25 ℃ is that the near-boiling mixture of 80% normal hexane-20% methylcyclopentane enters with the flow rate of 100kg / h by the 29th plate, controls ionic liquid and The mass ratio of the raw materials is 1:5, the steam rising from the top of the tower is condensed by the top condenser, and the reflux liquid is refluxed from the top of the tower. The output at the top of the tower is 780kg / h, and the n-hexane product with a mass fraction of 99.03% is obtaine...

Embodiment 3

[0071] In this experiment example, the figure 1 The system of the shown separation normal hexane and methylcyclopentane, concrete flow process is as follows:

[0072] The actual number of plates in the extractive distillation column is 45, the operating pressure is normal pressure, the operating reflux ratio is 3.6, the temperature at the top of the tower is controlled at 68-69°C, the temperature at the bottom of the tower is 138-139°C, and the ionic liquid at 25°C [C 10 Im] [SCN] enters by tower top, and the massfraction of 25 ℃ is that the near-boiling mixture of 85% normal hexane-15% methylcyclopentane enters with the flow rate of 100kg / h by the 27th plate, controls ionic liquid and The mass ratio of the raw materials is 1:5, the steam rising from the top of the tower is condensed by the top condenser, and the reflux liquid is refluxed from the top of the tower. The output of the top of the tower is 840kg / h, and the n-hexane product with a mass fraction of 99.10% is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com