Thin optoelectronic modules with apertures and their manufacture

A technology of active optics and optical devices, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of increasing the space occupied by optoelectronic modules, and achieve the effect of good optical isolation and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0410] In the following, a particularly elaborate approach is described, with various options and modifications which may, but do not necessarily need to, be part of the claimed invention.

[0411] With the aid of the described method, devices, more particularly optical devices, can be manufactured on the wafer level.

[0412] All figures are schematic representations only.

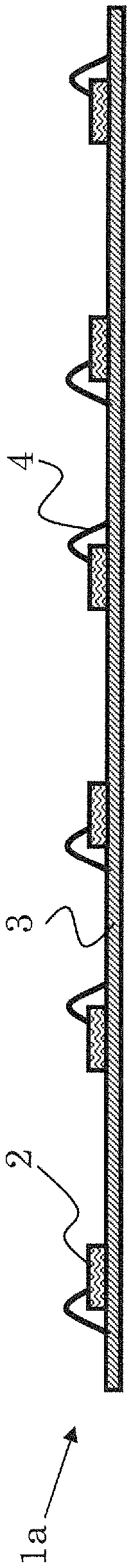

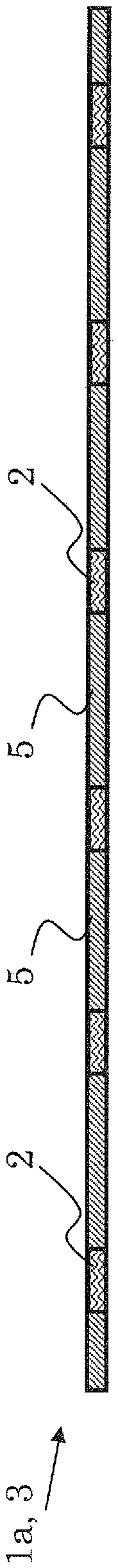

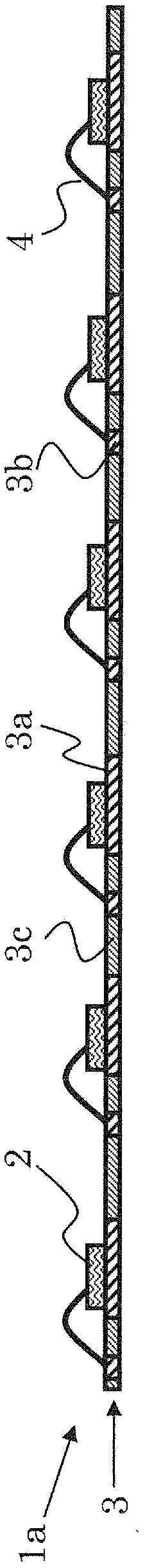

[0413] Figure 1A An initial wafer 1 a comprising a plurality of active optical components 2 and a wafer-scale substrate 3 is depicted in cross-sectional view.

[0414] Each active optical component 2 may be a light emitter, such as a light emitting diode (LED), a vertical cavity surface emitting laser (VCSEL), an edge emitting laser, an array of any of the foregoing, and / or any combination of any of the foregoing.

[0415] The light emitter may be operable to emit modulated light, such as spatially modulated light or temporally modulated light.

[0416] A light emitter may be operable to generate light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com