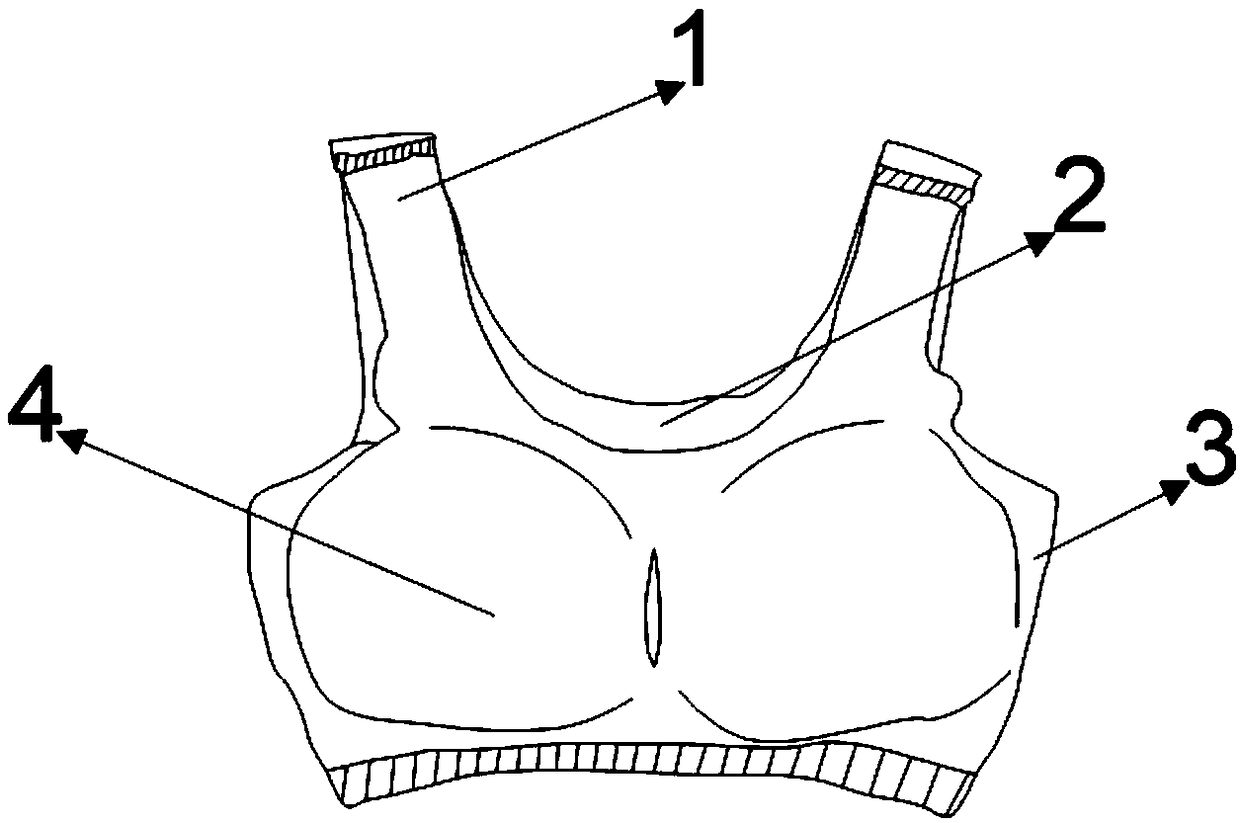

Super-comfortable seamless adhesion bra and manufacturing process thereof

A production process and seamless technology, applied in bras, clothing, bras, etc., can solve the problems of unfashionable styles and low tactile comfort, and achieve the effects of improving wearing comfort, accelerating metabolism, and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

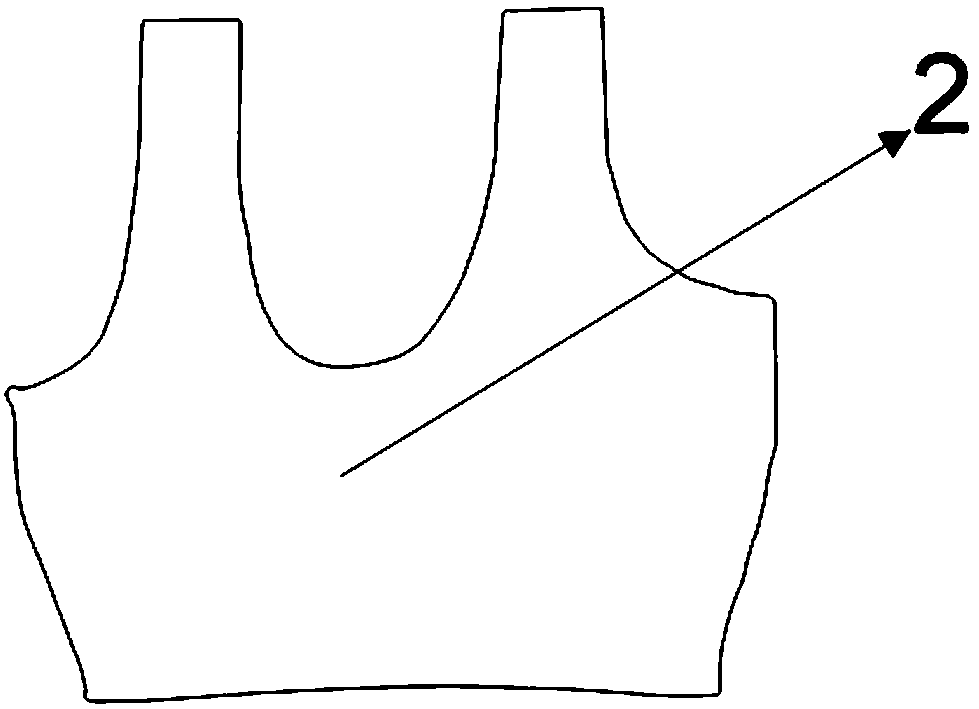

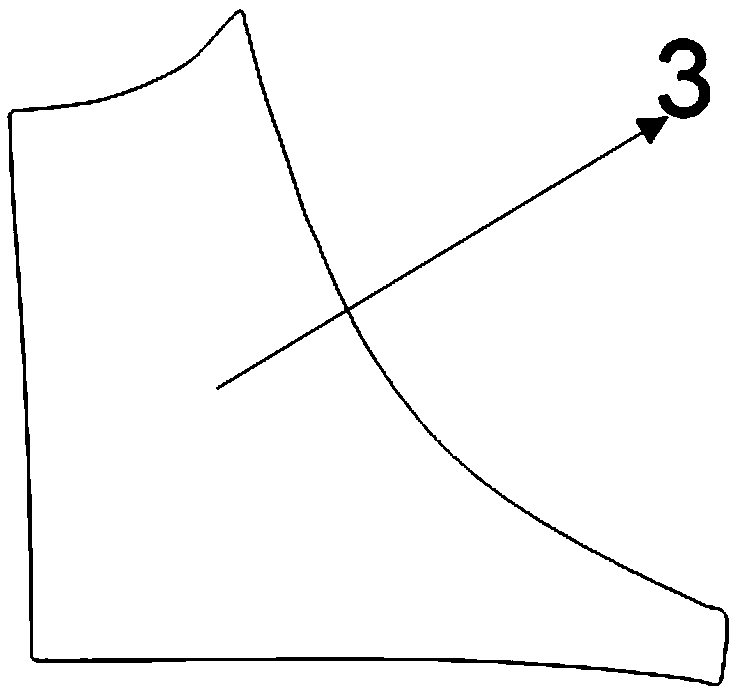

Embodiment 1

[0025] Firstly, the Italian Santoni underwear machine is used to carry out 360-degree seamless cloth weaving on the prepared ultra-fine denier Lenzing Modal yarn, and then the cloth is pretreated by boiling, mainly to remove natural impurities on the fabric, and in the weaving process Some oil stains produced make the fabric have good hygroscopicity, gloss, hand feeling and dimensional stability, so as to facilitate subsequent dyeing, dyeing with reactive dyes, first add an appropriate amount of refined salt to the dyeing vat, and adjust the pH value of the dyeing solution 8. Add reactive dyes, slowly contact the dyes in an alkaline salt bath, and slowly heat up to 60 degrees to achieve the best state of fabric coloring, then fix the color, wash with water, soften, dehydrate, and dry to shape, and the dyeing is completed The woven fabric is cut according to the paper pattern and the inner lining and the side support are cut. After the surface is printed, the negative ion far-in...

Embodiment 2

[0027] Prepare some ultra-fine denier Lenzing Modal yarns, use the Italian Santoni underwear machine to carry out 360-degree seamless fabric weaving on the prepared ultra-fine denier Lenzing Modal yarns, weave the fabrics for dyeing process, and boil the knitted fabrics before dyeing After scouring, dyeing with reactive dyes, slowly contacting the dyes, and slowly heating up to 60°, followed by color fixation, washing, softening, dehydration, and finally drying and finalizing, the dyed woven fabrics are cut and printed, and drawn according to the paper pattern Line cutting the inner lining and side support, and printing negative ion far-infrared temperature-changing magnetic therapy points on the front center of the inner lining fabric, doing heat-setting treatment, and finally testing the surface after printing, and the detection index negative ion content is 500-600 / Cubic centimeters, the normal emissivity of far infrared is 80-90%, and the wavelength range of far infrared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com