Puncture needle assembly with core

A technology of puncture needles and components, applied in the field of cored puncture needle components, can solve problems such as arterial-portal leakage, arterial-biliary leakage, portal vein-biliary leakage, liver cutting injury, recovery safety hazards, etc., to achieve convenient puncture work , to avoid cutting damage, to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

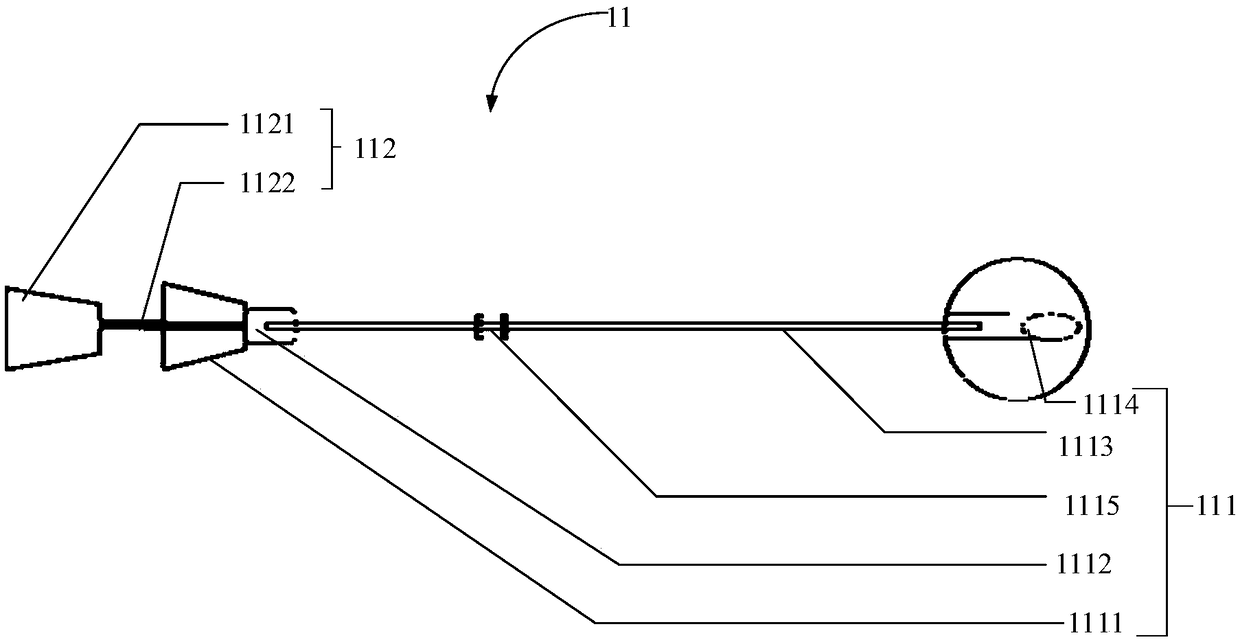

[0076] refer to Figure 1-2 , the present embodiment provides a cored puncture needle assembly 11, comprising:

[0077] External puncture needle 111 and detachable needle core 112;

[0078] The outer puncture needle 111 is provided with a cavity along its length direction for the detachable needle core 112 to penetrate;

[0079] The detachable needle core 112 can move along the length direction of the external puncture needle 111 in the cavity.

[0080] Preferably, the cored puncture needle assembly 111 further includes a guide wire 113;

[0081] The outer diameter of the guide wire 113 is smaller than the inner diameter of the cavity of the external puncture needle 111, so that after the detachable needle core 112 is pulled out, the guide wire 113 replaces the detachable needle core 112 to penetrate into the cavity.

[0082] Preferably, the outer diameter of the guide wire 113 is 0.035 inches;

[0083] The length of the guide wire 113 is 50 cm.

[0084] Preferably, the ...

Embodiment 2

[0087] refer to Figure 1-2 , this embodiment provides a cored puncture needle assembly 11, based on the above embodiments,

[0088] Preferably, the external puncture needle 111 includes a needle base 1111, a connecting tube 1112 and a needle tube 1113 connected in sequence;

[0089] The end of the needle tube 1113 facing away from the connecting tube 1112 is provided with a needle head 1114 .

[0090] Preferably, the external puncture needle 111 further includes a movable valve 1115 arranged on the needle tube 1113 and movable along the length direction of the needle tube 1113;

[0091] The movable valve 1115 is used to mark the length of the needle tube 1113 .

[0092] As mentioned above, the external puncture needle 111 includes a needle seat 1111, a connecting tube 1112, a needle tube 1113 and a needle head 1114. In addition, a movable valve 1115 that can reciprocate along the outside of the needle tube 1113 is provided in the length direction of the needle tube 1113, wh...

Embodiment 3

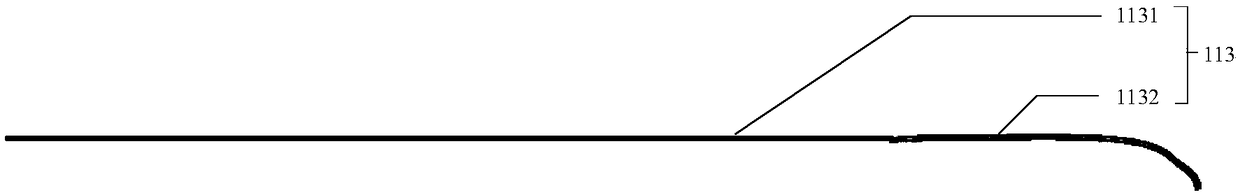

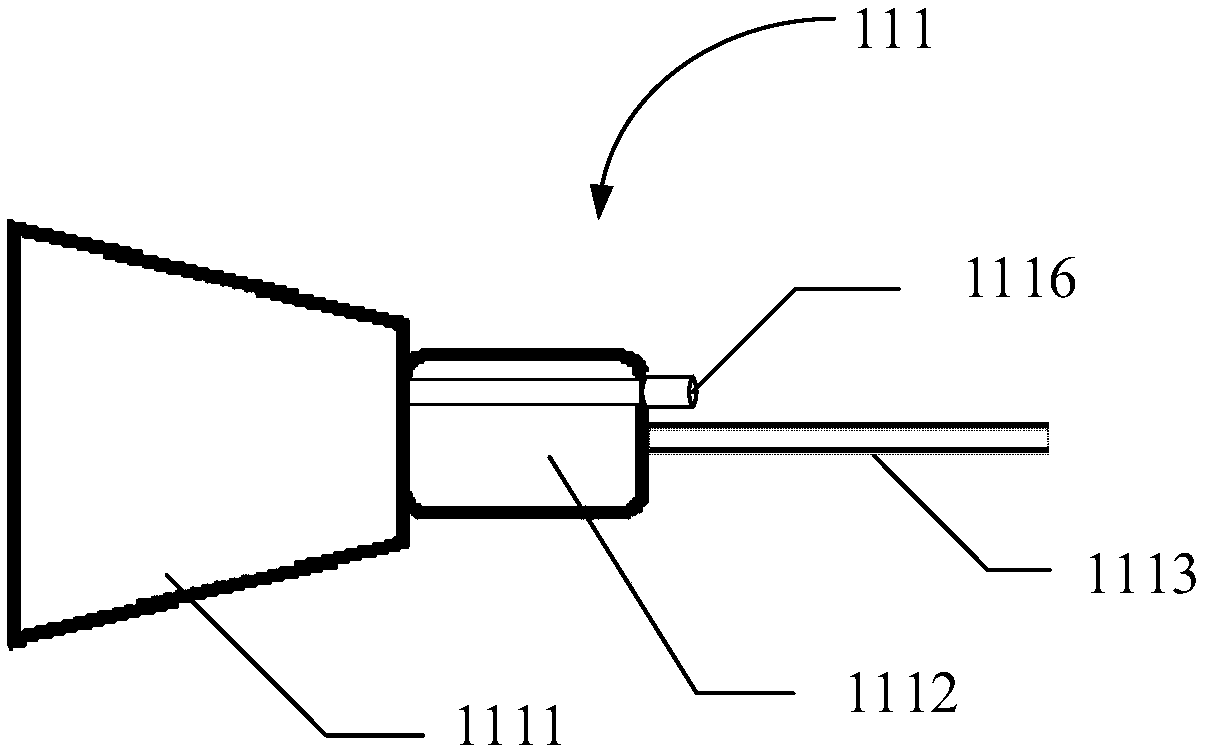

[0094] refer to Figure 3-4 , this embodiment provides a cored puncture needle assembly 111, based on the above-mentioned embodiment 1,

[0095] Preferably, the external puncture needle 111 includes a needle base 1111, a connecting tube 1112 and a needle tube 1113 connected in sequence;

[0096] The end of the needle tube 1113 facing away from the connecting tube 1112 is provided with a needle head 1114 .

[0097] Preferably, the connecting tube 1112 is provided with a laser positioner 1116 for emitting laser light in the direction of the needle 1114 for positioning.

[0098] Preferably, a scale is provided on the outside of the needle tube 1113 for measuring the puncture distance of the needle tube 1113 .

[0099] Preferably, the detachable core 112 includes a core base 1121 and a core tube 1122 connected to the core base 1121;

[0100] The core base 1121 is provided with a threaded connector connected with the needle base 1111 .

[0101] The core base 1121 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com