Vacuum pressurization impregnation apparatus for preparing ceramic matrix composite material through PIP method

A technology of vacuum pressure impregnation and composite materials, which is applied in the field of vacuum pressure impregnation equipment, which can solve the problems that the impregnation efficiency of precursors cannot be improved well, the heating method is too severe and uneven, and the method is complicated, so as to improve the impregnation efficiency and quality, improved impregnation efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

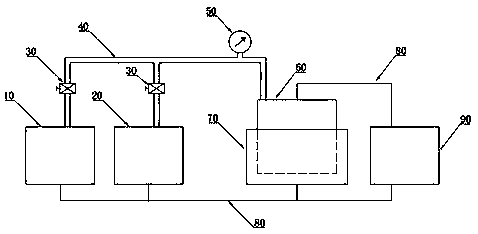

[0020] Vacuum pressure impregnation equipment for PIP ceramic matrix composites, such as figure 1 As shown, it includes an impregnation device 60, a water bath heating device 70, a pressurizing device 10, a vacuum device 20, and a power control device 90; the pressurization device 10, the vacuum device 20 and the impregnation device 60 are connected by a stainless steel pipe 40, and the inner diameter of the steel pipe is 10mm, the pipe is equipped with a ball valve 30 and a pressure gauge 50; the water bath heating device 70 is wrapped around the impregnation device 60, which can heat and keep the impregnation device. The working temperature range is 20~100°C, and the temperature is measured by a thermocouple; It is a pressurizing pump, and the vacuuming device is a vacuum pump; the power control device 90 controls the dipping device 60 , the water bath heating device 70 , the pressurizing device 10 and the vacuuming device 20 sequentially through the power cord 80 .

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com