Preparation method for hard alloy product with composite structure

A cemented carbide and composite structure technology, applied in the field of cemented carbide, can solve problems such as incomplete bonding and deformation, and achieve the effects of low manufacturing cost, simple process, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 15

[0108] Embodiment 15, preparation steps are as follows:

[0109] (1) Prepare the mixture required for the inner layer and the outer layer through batching, ball milling, and drying by conventional powder metallurgy technology, and set aside. The material of the inner layer is WC-15wt.% (Co+Ni+Fe), and the material of the outer layer is: WC-7wt.% TiC-2wt.% TaC-12wt.% (Co+Ni+Cr).

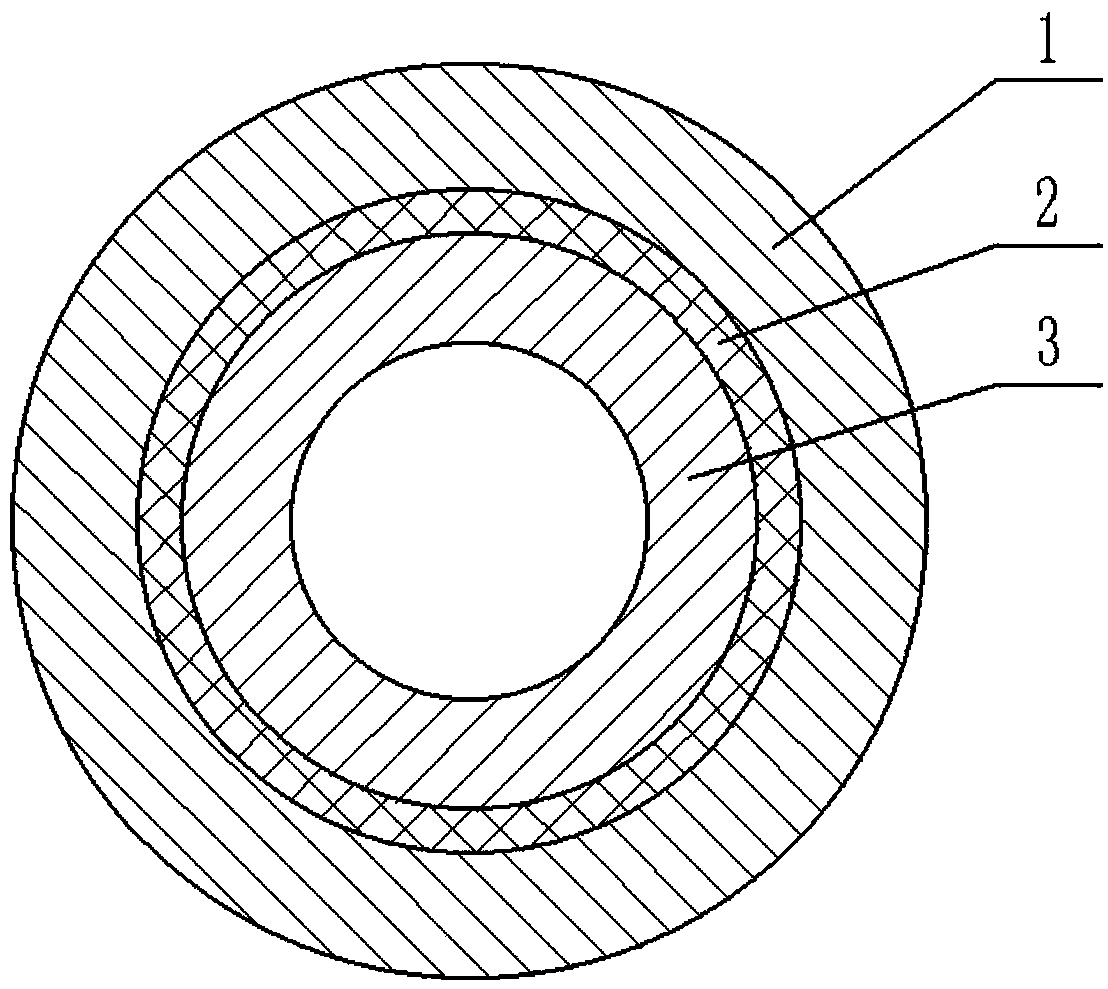

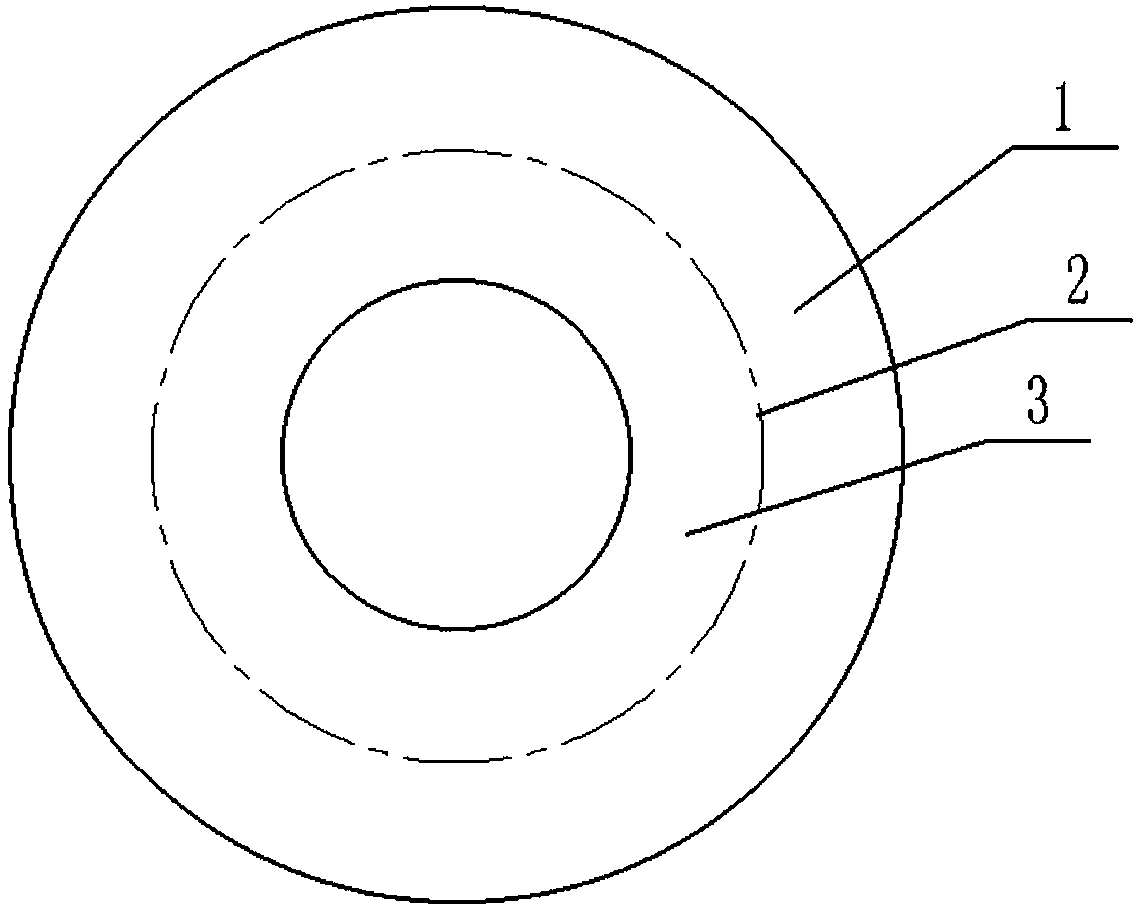

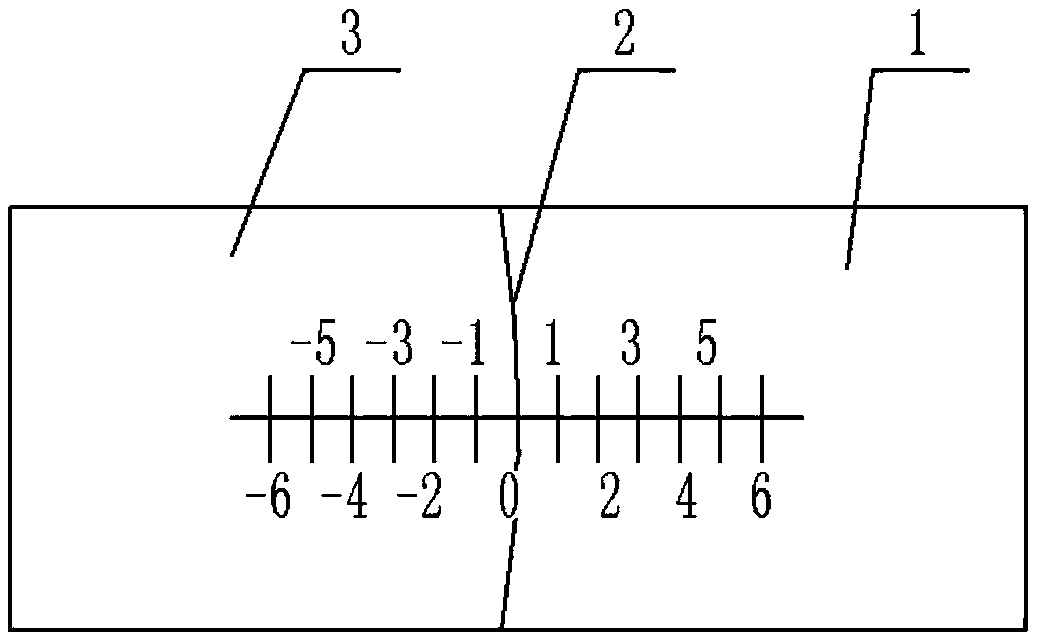

[0110] (2) The mixture prepared in step (1) is separately molded to prepare an inner layer compact and an outer layer compact, wherein the size of the outer layer compact is about (ring, independent sintering shrinkage coefficient K 外 =1.30), the size of the inner compact is about (ring, independent sintering shrinkage coefficient K 内 = 1.20).

[0111]

[0112] (3) Set the inner and outer compacts of step (2) together, put them in a boat and put them into a furnace for sintering, the sintering temperature is 1450°C, after the sintering is completed, cut off the power, cool down, and come out ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap