A glass-lined steel with excellent plasticity, toughness and scale explosion resistance and its manufacturing method

A manufacturing method and glass-lined technology, applied in the field of glass-lined steel, can solve the problems of complex processing and forming, poor service environment, and no impact energy, achieve excellent plasticity and low-temperature toughness, good quality of coated surface, and prevent excessive growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

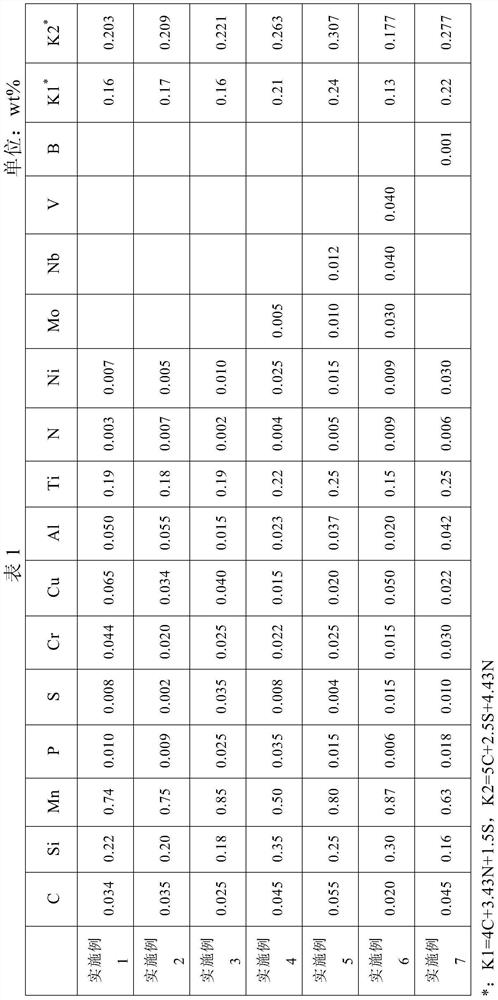

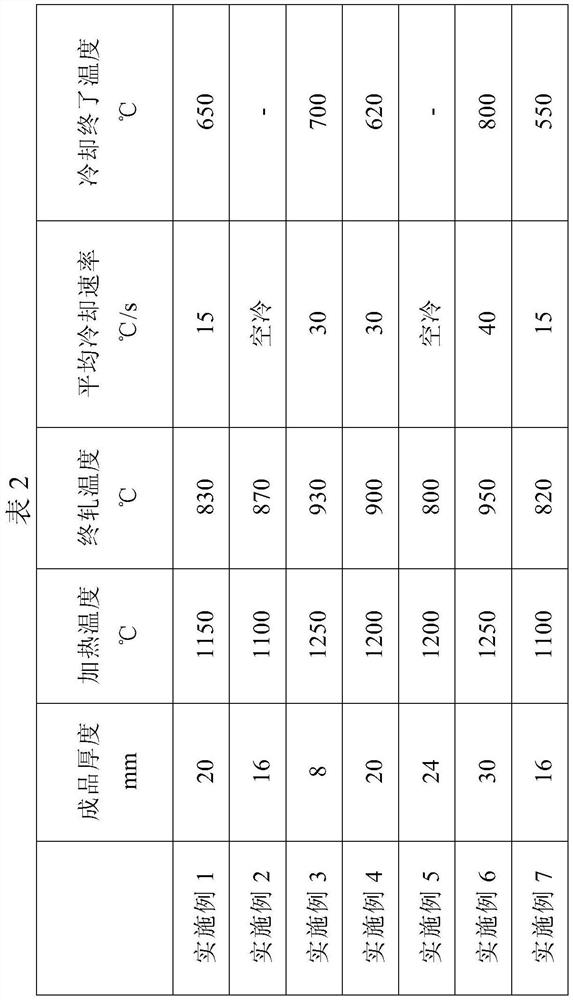

[0049] The technical solution of the present invention will be further described in detail based on Examples 1 to 7 and Comparative Example 1 below.

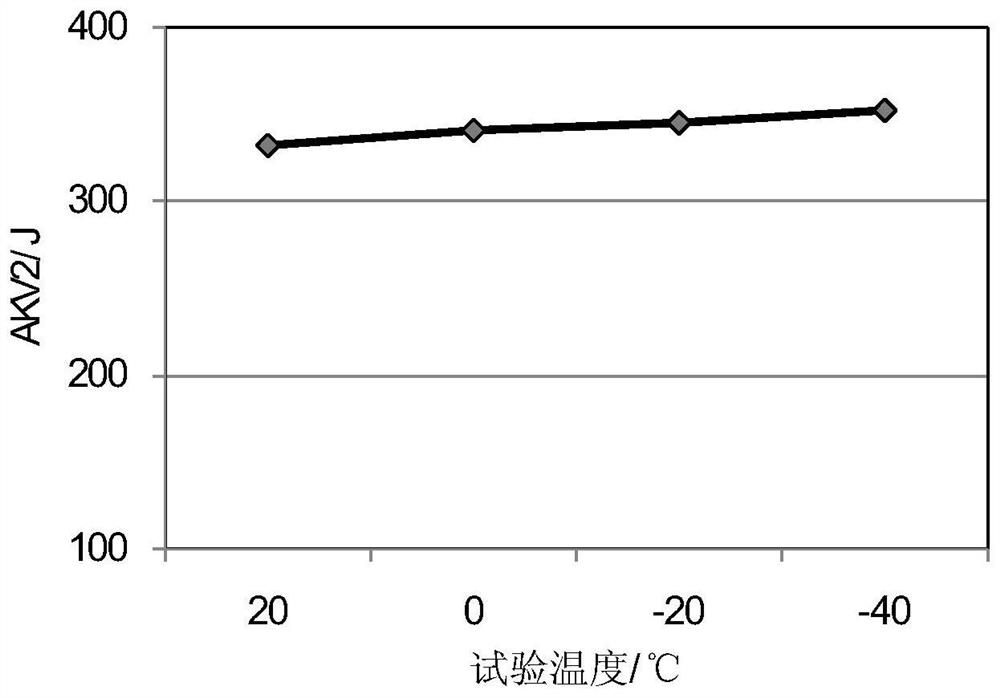

[0050] Table 1 is the composition of the steel examples of the present invention, Table 2 is the process parameters of the steel examples of the present invention, and Table 3 is the performance of the examples of the present invention, including tensile properties and impact energy (both transverse sampling).

[0051] Manufacture glass-lined steel of the present invention according to the following steps:

[0052] 1) The molten steel is subjected to converter blowing and vacuum degassing;

[0053] 2) Continuous casting;

[0054] 3) After the billet is heated at 1100-1250°C, multi-pass rolling is carried out, and the final rolling temperature is controlled at 800-950°C. Steel plates with a thickness of 2-15mm can be rolled by a hot rolling mill. For thickness ≥ 8mm The steel plate can be rolled by a single-stand hot rolling mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com