Construction method with limestone decoration effect based on heat preservation base layer

A technology of decorative effects and construction methods, applied in covering/lining, construction, building construction, etc., can solve problems such as cracking of decoration walls, achieve the effects of preventing cracking, reducing construction costs, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

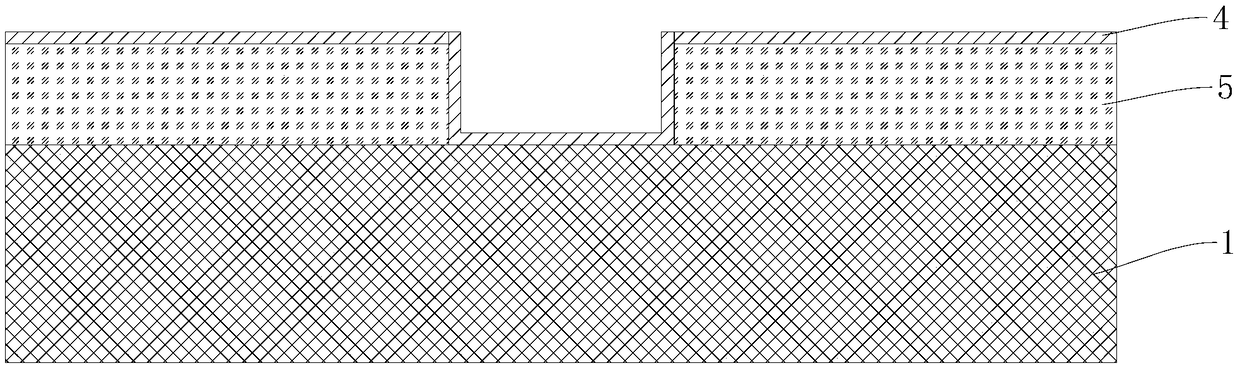

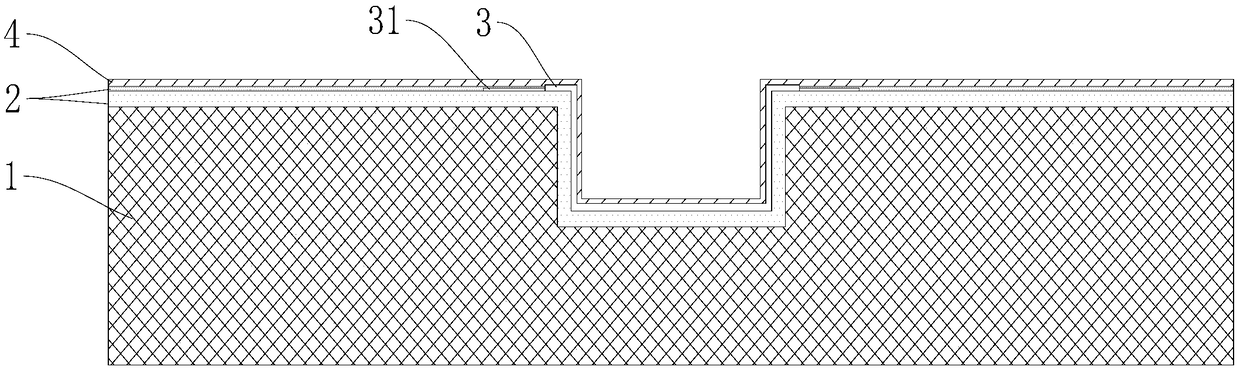

[0022] (1) The thermal insulation board is pasted on the surface of the wall with an adhesive to form the thermal insulation base layer 1, and the elastic line is divided to determine the position of the French seam 6, and the thermal insulation base layer 1 is slotted with a slotting machine to obtain a depth of 4 mm and a width of 4 mm. 2.2cm French seam6. After the slotting is completed, apply anti-cracking mortar on the insulation base 1 and the French joint 6. After it dries, install the divider 3 on the French joint 6. The width of the notch of the divider 3 is 2cm. The divider 3 here comprises a divider 3 main body, and both sides of the divider 3 main body are provided with mesh cloth 31 , and the width of the mesh cloth 31 is 10 cm. What needs to be explained here is that the partition strip 3 is a prior art, and can be customized according to the specific size of the French seam 6 .

[0023] Fix the grid cloth 31 on both sides of the partition bar 3 to the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com