Manufacturing method of in-mould labels

A production method and in-mold labeling technology are applied in the fields of cosmetics and gift packaging, wine and cigarettes, and can solve the problems of laser relief application and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

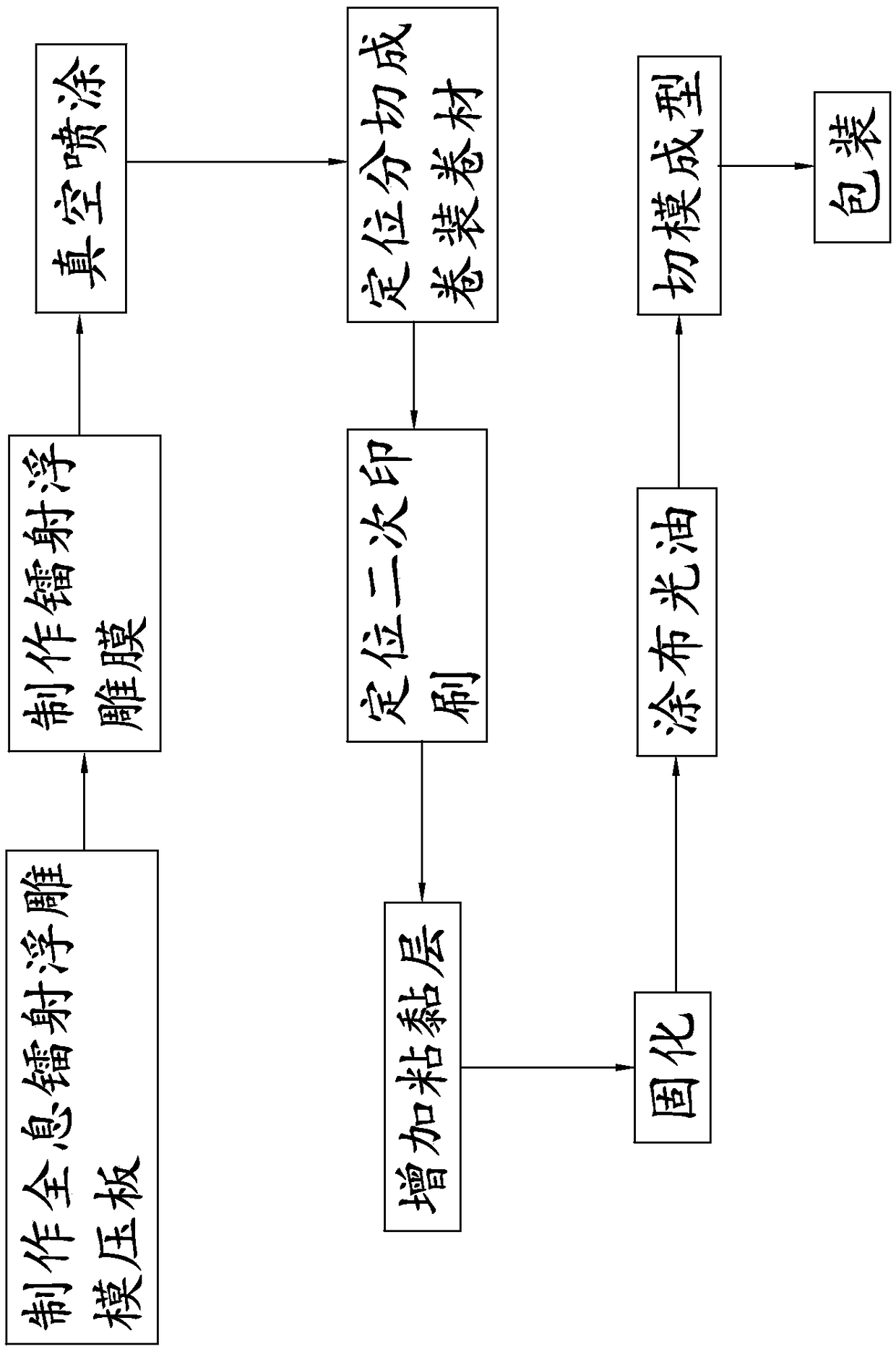

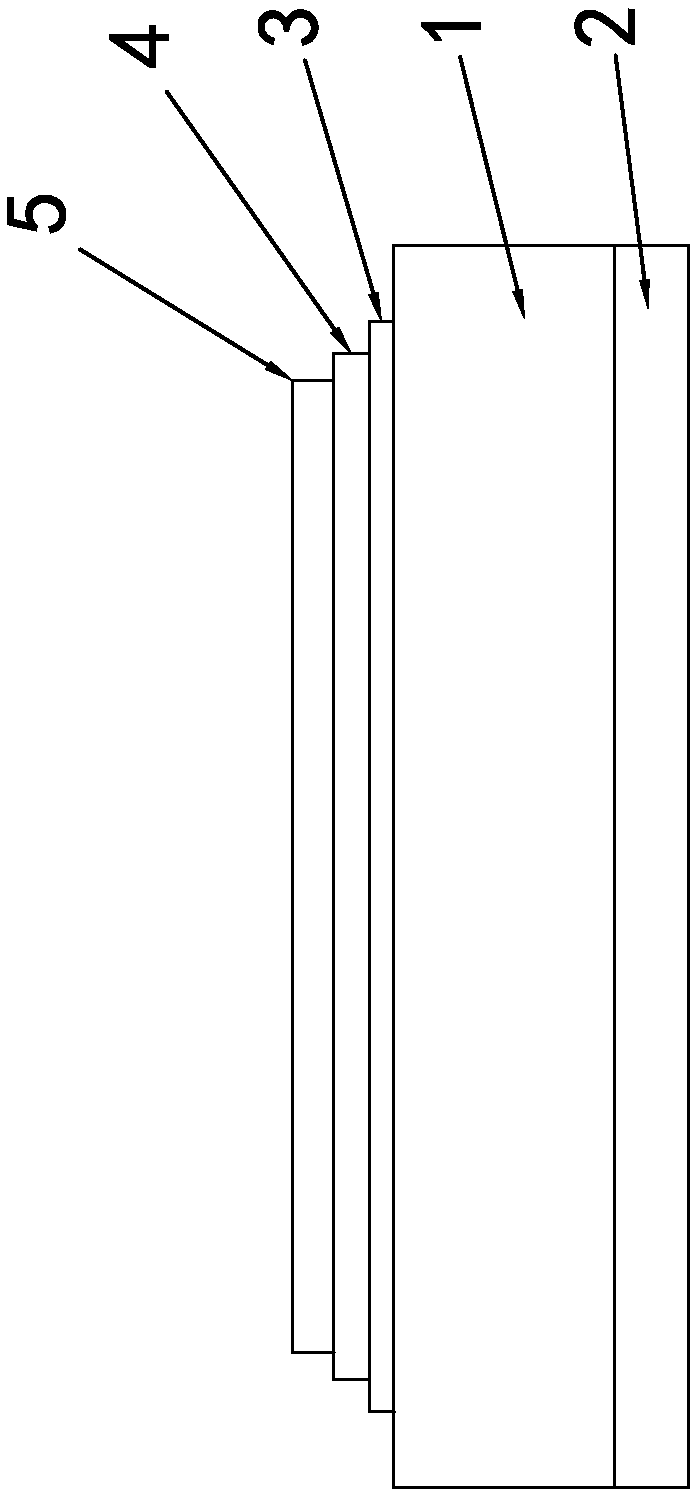

[0034] refer to figure 1 with figure 2 , The invention is a method for making an in-mold label.

[0035] Laser holography technology uses the basic laws of scattering, reflection, transmission, diffraction, interference, absorption, etc. when light is irradiated by matter, and then forms different visual effects. A high-energy laser beam is generated by a laser generator, and the nickel plate is partially irradiated by engraving or vector contour cutting in a dot matrix to make the surface instantly melt or even gasify. At this time, the material on the surface of the nickel plate is chemically And physical changes show traces, and then form the required characters, symbols and patterns according to the pre-design requirements. After the laser beam is focused, the processing accuracy is at the millimeter to micron level, and the heat-affected area in the laser processing process is small, and the final processed surface is of high precision, which is why the laser is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com