Battery cell of semi-winding laminated lithium-ion battery and preparation method of battery cell

A lithium-ion battery, cell technology, applied in secondary batteries, circuits, electrical components, etc., to achieve the effect of improving consistency, improving thermal cycling, and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

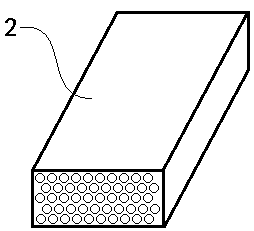

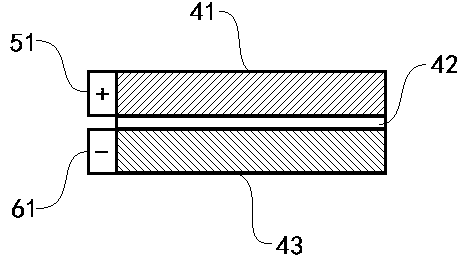

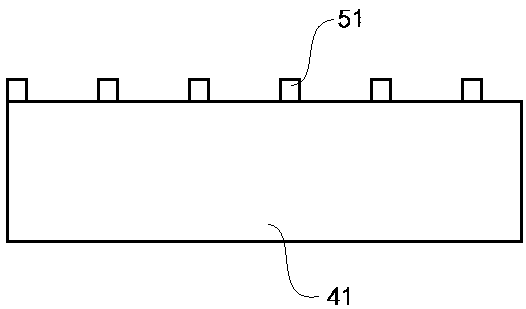

[0034] see figure 1 , 4 As shown in ~6, a half-wound laminated lithium-ion battery cell includes a cell casing 1, and the outside of the cell casing 1 is provided with a positive pole pole 11 and a negative pole pole 12. The inside of the core housing 1 is provided with a flat mandrel 2, a diaphragm bag 3, an electrode strip 4 and an electrolyte; the flat mandrel 2 is a square bracket made of a heat-conducting material, and the inside of the square bracket is It has a honeycomb or grid-like hollow structure, the electrolyte is injected into the honeycomb or grid-like hollow structure inside the flat mandrel 2, and the diaphragm bag 3 is wrapped outside the flat mandrel 2; The polarity belt 4 is wound on the flat mandrel 2 wrapped with the diaphragm bag 3, and fixed into a square structure, and the positive pole 5 and the negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com