Side slope protection hydraulic spray machine and spraying grass-planting method using same

A technology of slope protection and spraying machine, which is applied in the direction of sowing seeders, planter parts, sowing, etc., can solve the problems of affecting spraying efficiency and spraying quality, easy clogging, high material concentration, etc., to eliminate visual fatigue, It is convenient for complete discharge and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

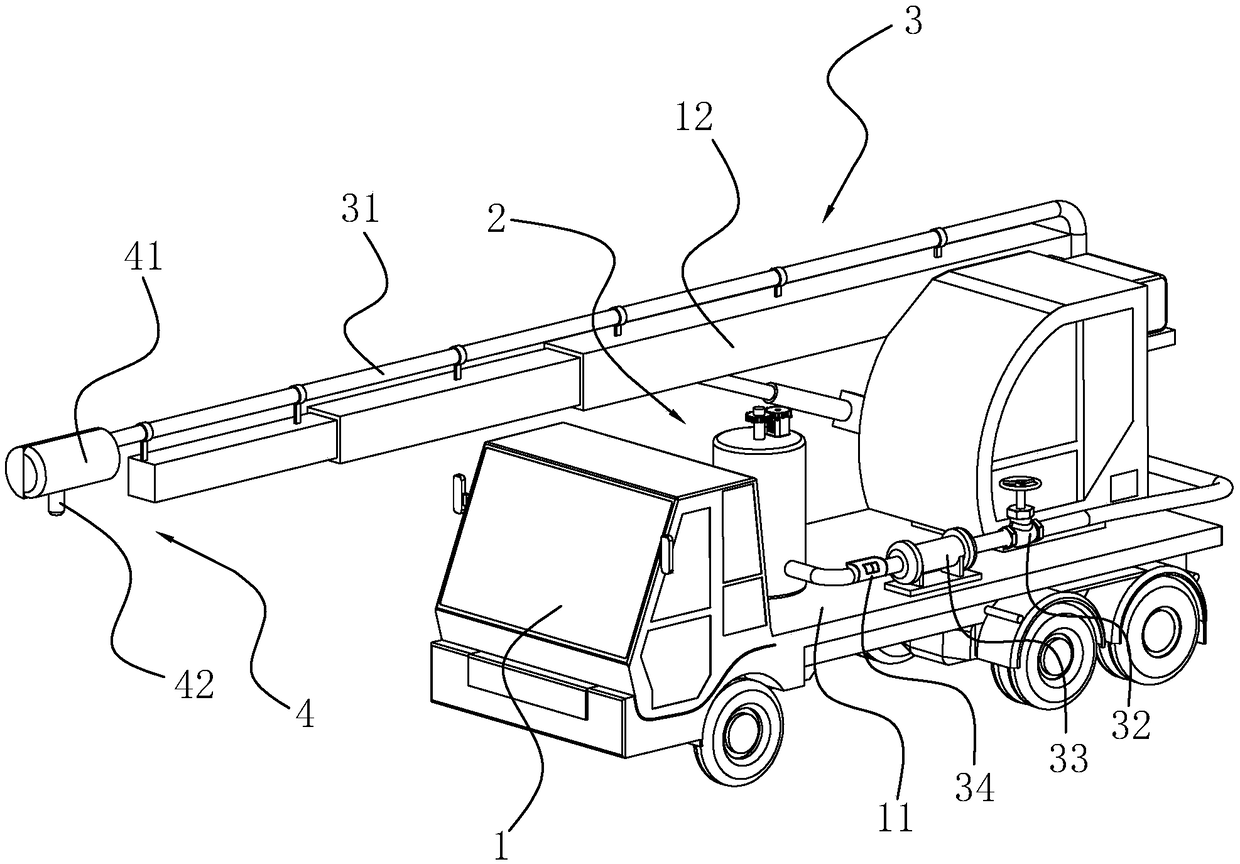

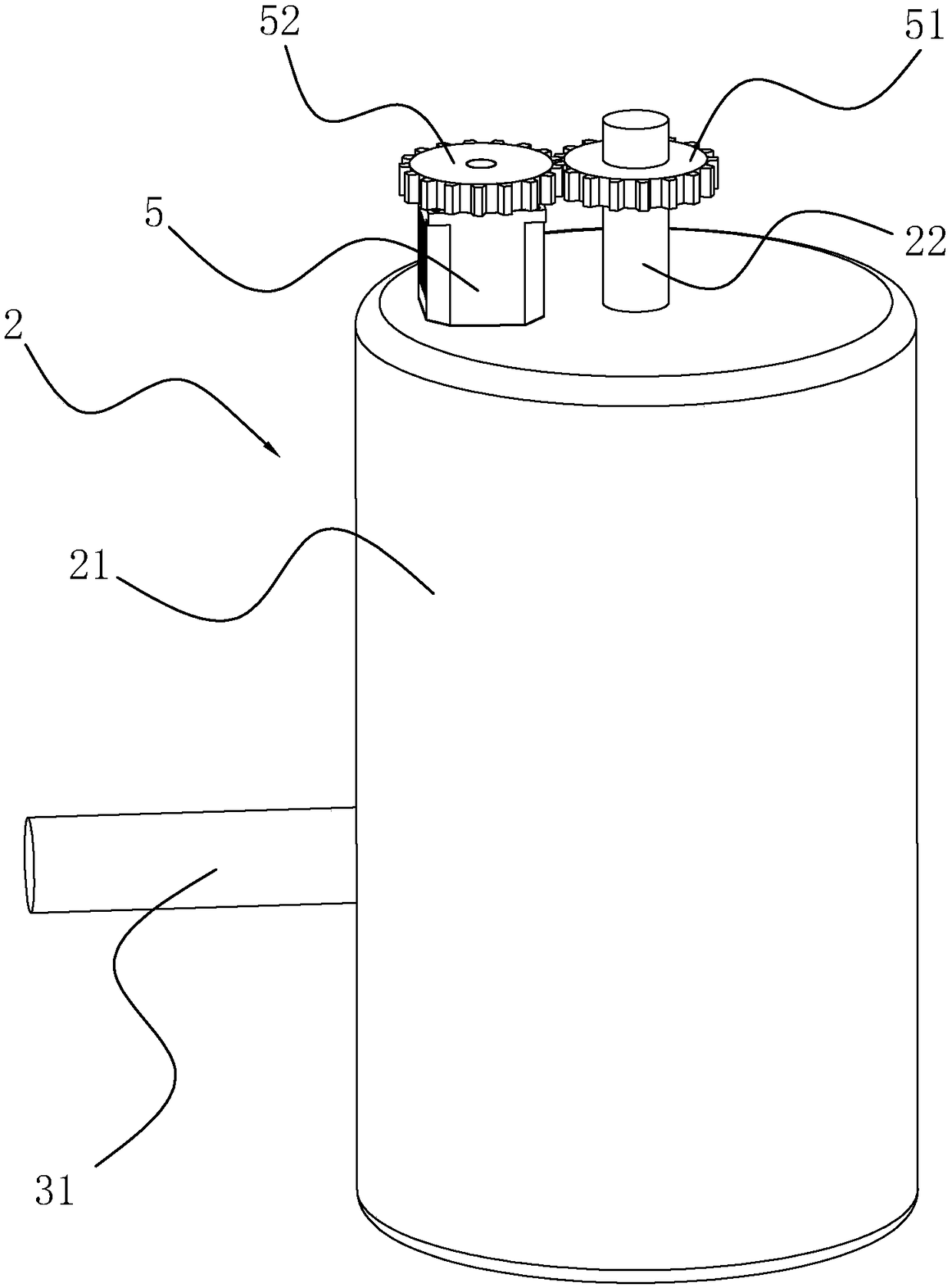

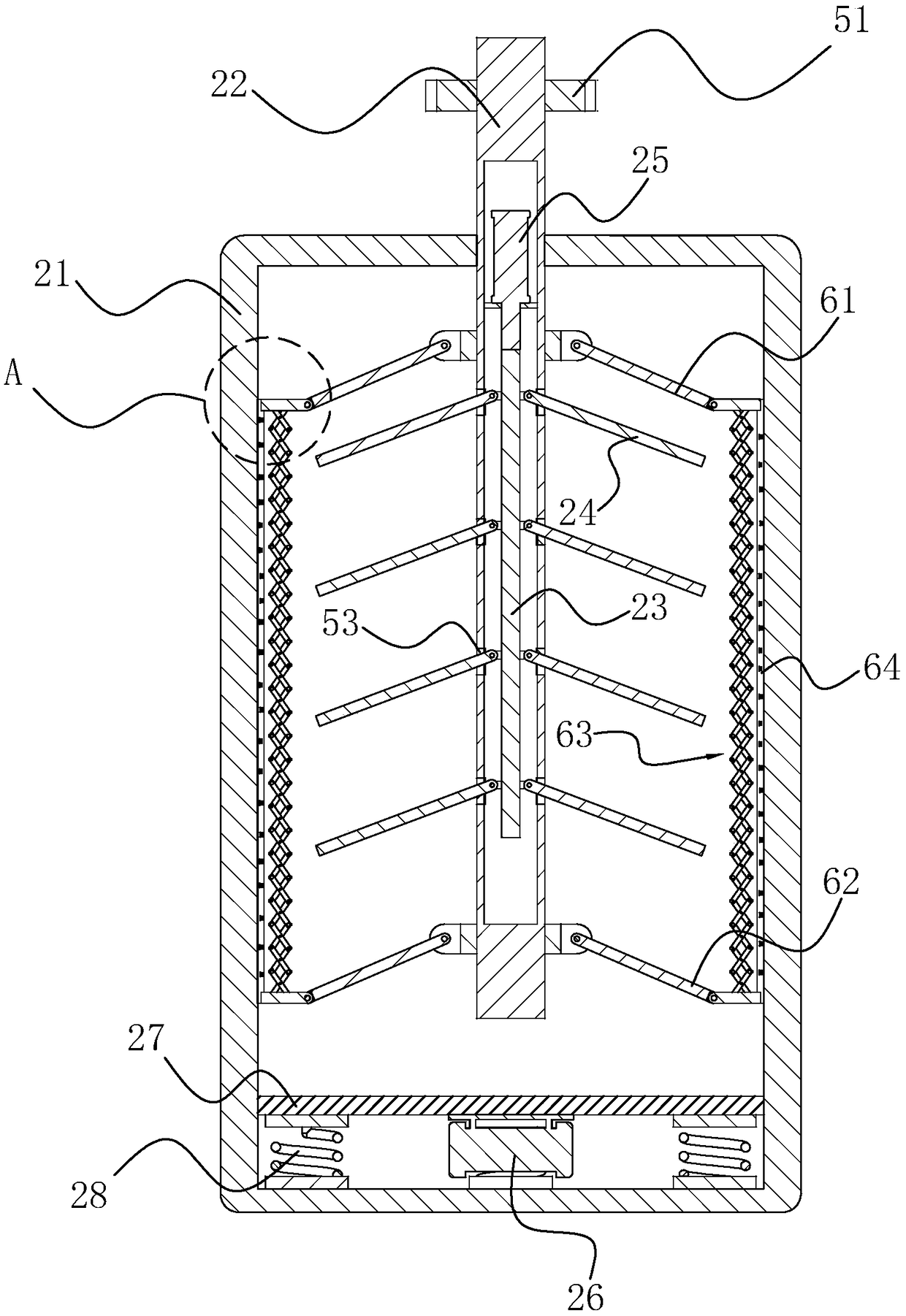

[0049] A side slope protection hydraulic sprinkler, such as figure 1 As shown, the transport vehicle 1 is included, and the transport vehicle 1 is provided with a stirring mechanism 2, a material delivery mechanism 3 and a spraying mechanism 4, wherein the stirring mechanism 2 is installed on the base 11 of the transport vehicle 1, and the material delivery mechanism 3 is installed along the transport vehicle 1. The cantilever 12 of 1 is fixed, and the spraying mechanism 4 is connected with the spraying mechanism 4 through the feeding mechanism 3 and is arranged on the end of the cantilever 12 away from the stirring mechanism 2, so before the hydraulic spraying, the glue of grass seeds and water The mixed slurry will be fully uniform under the action of the stirring mechanism 2, and then transferred to the spraying mechanism 4 at the end of the cantilever 12 through the conveying mechanism 3, so as to spray and sow the side slope.

[0050] In order to be suitable for stirring ...

Embodiment 2

[0060] Embodiment 2: a kind of method for planting grass by spraying that is applied to embodiment 1, comprises the following steps:

[0061] S1. Slope surface modification: Manually remove stones, tree roots, plastics and other debris, and properly level the slope, and level the slope with a height difference of more than 20cm;

[0062] S2. Slope covering soil: stack ecological bags on the slope to form a step shape, and cover a layer of planting soil on the step surface of the ecological belt before taking a solid shot;

[0063] S3. Material selection: the grass species adopts Bermudagrass and Bahia grass with a ratio of 7:3, and the fiber is wood fiber to provide a seedbed for seed germination. The amount of fiber used is 65-90 kg / mu, and can be adjusted appropriately according to the terrain , increase the dosage when the slope is large;

[0064] S4, material spraying configuration: first add water in material storage tank 21, then add grass seed, fertilizer, active calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com