Milk mineral salt and DHA gel soft candy and manufacture method thereof

A technology of milk mineral salt and gel soft candy, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of chewiness, unsatisfactory elasticity, poor thermal stability, soft candy hardness and chewiness decrease, etc. To achieve the effect of uniform and fine texture, good thermal stability, improved absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

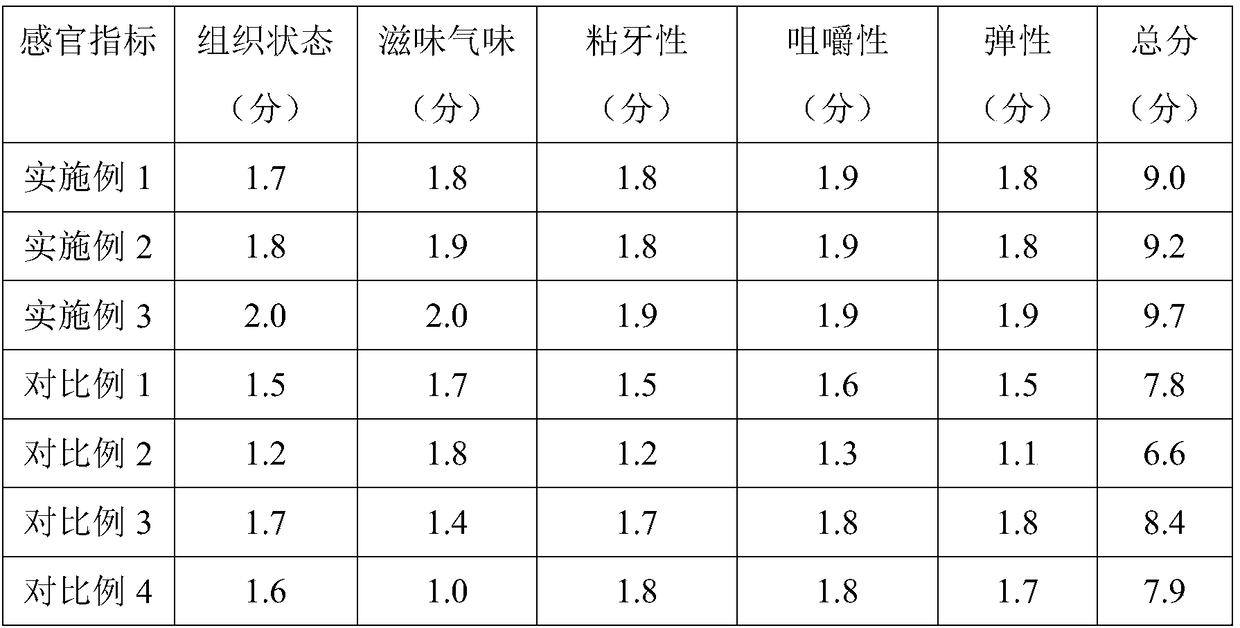

Examples

Embodiment 1

[0028] Embodiment 1, a kind of milk mineral salt DHA jelly candy

[0029] The milk mineral salt DHA jelly jelly is composed of the following components and their mass parts: 0.5 part of milk mineral salt, 0.2 part of algae oil DHA, 2.5 parts of gelling agent, 1 part of flavor regulator, 30 parts of glucose syrup, 0.5 part of casein phosphopeptide, 1 part of calcium gluconate, 25 parts of white granulated sugar and 25 parts of water; said gel consists of gelatin, sodium alginate, konjac gum and guar gum in mass ratio 10:9:5: 2 composition; the flavor regulator is composed of citric acid and L-malic acid in a mass ratio of 2:11.

[0030] The soft manufacturing method of described milk mineral salt DHA gel is:

[0031] S1 Add water to the gel, the amount of water added is twice the mass of the gel, heat to 60°C, keep warm for 1 hour, and get the glue;

[0032] S2 Add water to the flavor modifier, the amount of water added is 1.5 times the quality of the flavor modifier, stir ev...

Embodiment 2

[0036] Embodiment 2, a kind of milk mineral salt DHA jelly

[0037] The milk mineral salt DHA gel jelly is composed of the following components and their mass parts: 1 part of milk mineral salt, 0.4 part of algae oil DHA, 4 parts of gelling agent, 1.5 parts of flavor regulator, and 40 parts of glucose syrup , 1 part of casein phosphopeptide, 3 parts of calcium gluconate, 32 parts of white granulated sugar and 30 parts of water; the gel is composed of gelatin, sodium alginate, konjac gum and guar gum in a mass ratio of 15:7:3 :1 composition; the flavor regulator is composed of citric acid and L-malic acid in a mass ratio of 5:8.

[0038] The soft manufacturing method of described milk mineral salt DHA gel is:

[0039] S1 Add water to the gel, the amount of water added is 3 times the mass of the gel, heat to 70°C, keep it warm for 2 hours, and get the glue;

[0040] S2 Add water to the flavor modifier, the amount of water added is 1.5 times the quality of the flavor modifier, ...

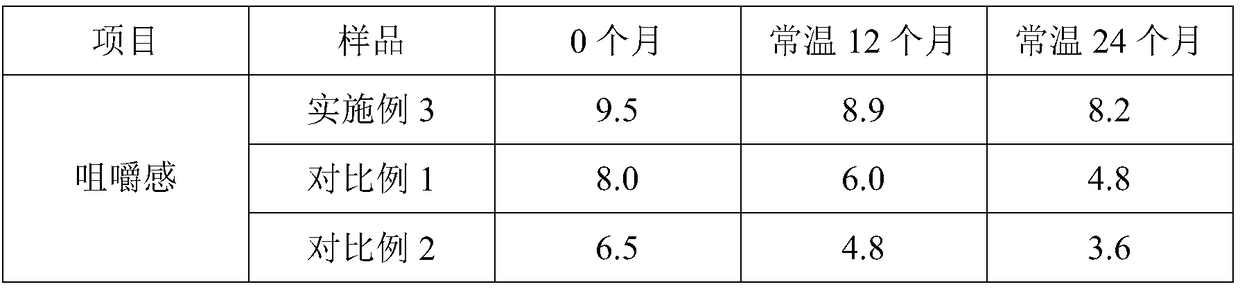

Embodiment 3

[0044] Embodiment 3, a kind of milk mineral salt DHA jelly candy

[0045] The milk mineral salt DHA jelly candy is composed of the following components and their mass parts: 0.8 parts of milk mineral salt, 0.3 parts of algae oil DHA, 3 parts of gelling agent, 1.2 parts of flavor regulator, and 36 parts of glucose syrup , 0.7 part of casein phosphopeptide, 2 parts of calcium gluconate, 28 parts of white granulated sugar and 28 parts of water; the gel is composed of gelatin, sodium alginate, konjac gum and guar gum in a mass ratio of 14:8:4 : 1 composition; the flavor regulator is composed of citric acid and L-malic acid in a mass ratio of 3:10.

[0046] The soft manufacturing method of described milk mineral salt DHA gel is:

[0047] S1 Add water to the gel, the amount of water added is 2.5 times the mass of the gel, heat to 65°C, keep warm for 1.5h, to obtain the glue;

[0048] S2 Add water to the flavor modifier, the amount of water added is 1.5 times the quality of the flavo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com