A dust collector for a plastic spraying machine

A recycling device and plastic spraying machine technology, applied in the direction of injection devices, etc., can solve the problems of complex structure, loud noise, slow plastic powder falling, etc., and achieve the effect of good recycling effect, low noise and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

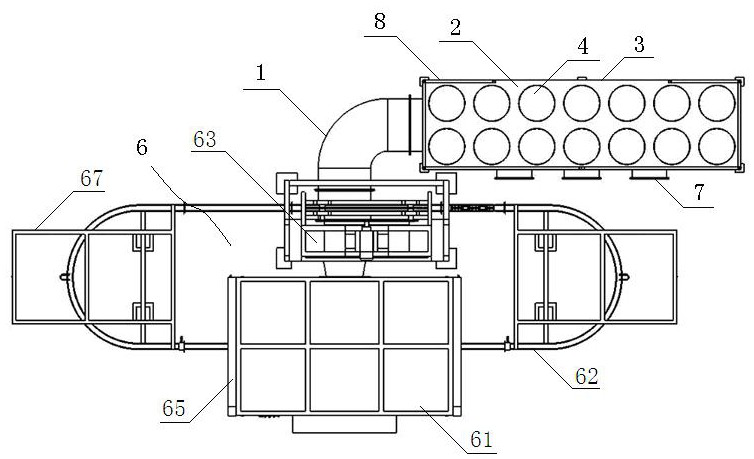

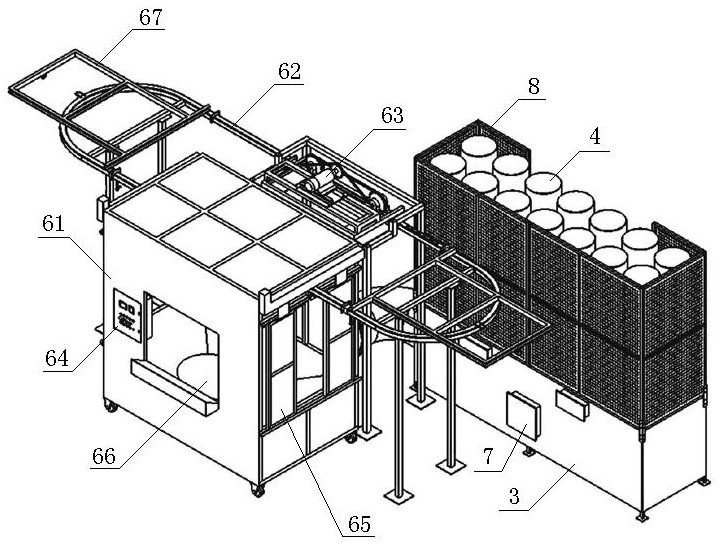

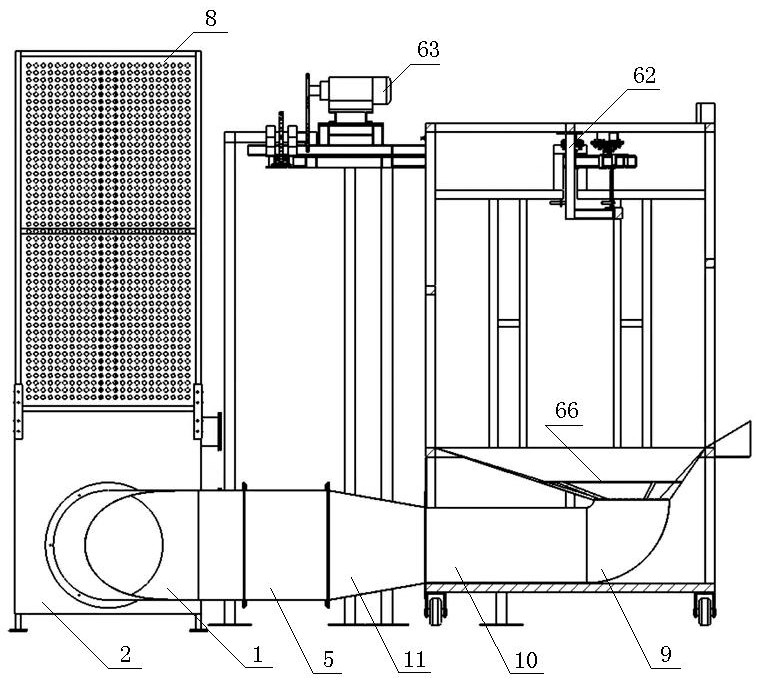

[0023] A dust suction recovery device for a plastic spraying machine, comprising a connecting pipe 1 and a recovery mechanism 2, the recovery mechanism 2 comprising a recovery box 3 and several dust suppression cylinders 4 installed on the recovery box, the dust suppression cylinders 4 are closed at one end and open at the other end The same hollow cylinder as the opening of the dust reduction tube is set on the top plate of the recovery box 3, the opening end of the dust suppression tube is installed on the opening of the recovery box, the powder pulling fan 5 is installed in the middle of the connecting pipe 1, and one end of the connecting pipe 1 is connected to the Plastic powder diffusion unit 6, the other end is connected to recovery box 3.

Embodiment 2

[0025] As a kind of preference of embodiment 1, partition board is set in the middle of described recovery box 3, and partition board divides recovery box into lower recovery box, upper recovery box, and partition board is provided with recovery box opening at the same position as top plate, and described dust-reducing tube 4 At least two layers of cylinders are included, the bottom of the outer cylinder is installed on the opening of the outer surface recovery box on the top of the upper recovery box, the bottom of the inner cylinder is installed on the outer surface of the top of the lower recovery box and is located in the box of the upper recovery box, The inner cylinder is a hollow cylinder, and the wall of the outer cylinder and the inner cylinder are hollow.

Embodiment 3

[0027] As a preference of Embodiment 2, several through holes are provided on the wall of the inner cylinder, and the through holes connect the inner cylinder and the space between the inner cylinder and the outer cylinder.

[0028] There are an even number of the dust suppression cylinders 4 .

[0029] The dust suppression tube 4 is configured as a cylinder, and the box body is a cuboid.

[0030] On the recovery box 3, a recovery opening is set, and a recovery opening door 7 is installed on the recovery opening, one is set on the lower recovery box, and two are set on the upper recovery box.

[0031] Protective mesh panels 8 are arranged on the four sides of the box body of the recovery box 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com