Iron concentrate storage and transportation system

A technology for iron ore concentrate and concentrate, which is applied in the directions of transportation and packaging, loading/unloading, conveyors, etc., can solve the problem of increasing the energy consumption of pelletizing or sintering operations, increasing the consumption of loading machinery and manpower, and reducing the effective storage of ore piles. Mineral volume and other issues, to achieve the effect of reducing maintenance costs and labor costs, improving loading efficiency, and high loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

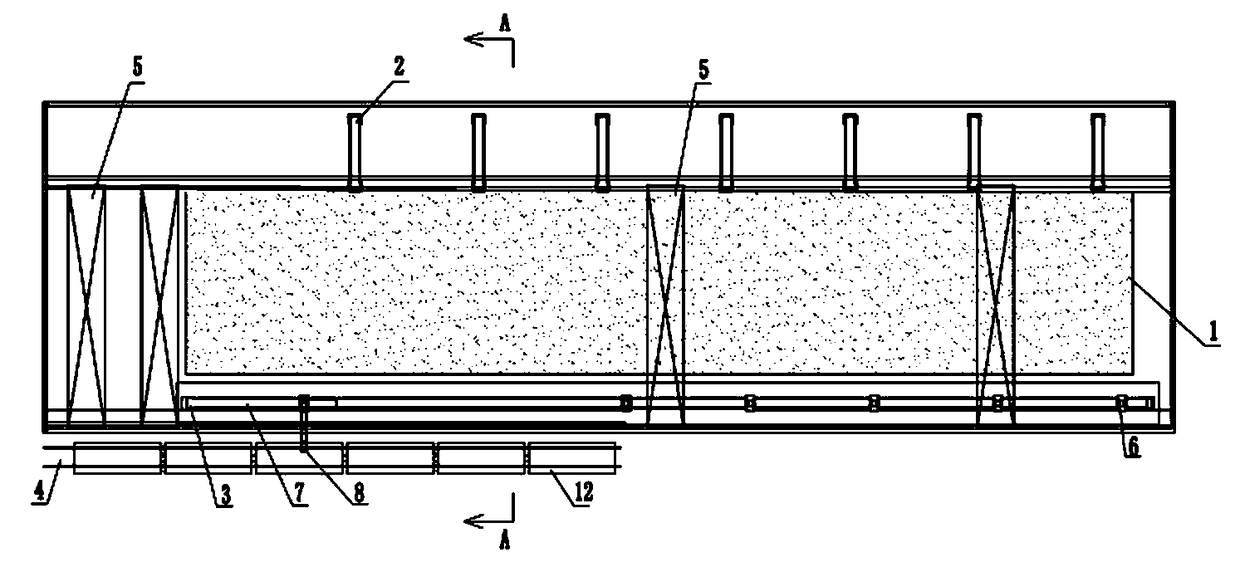

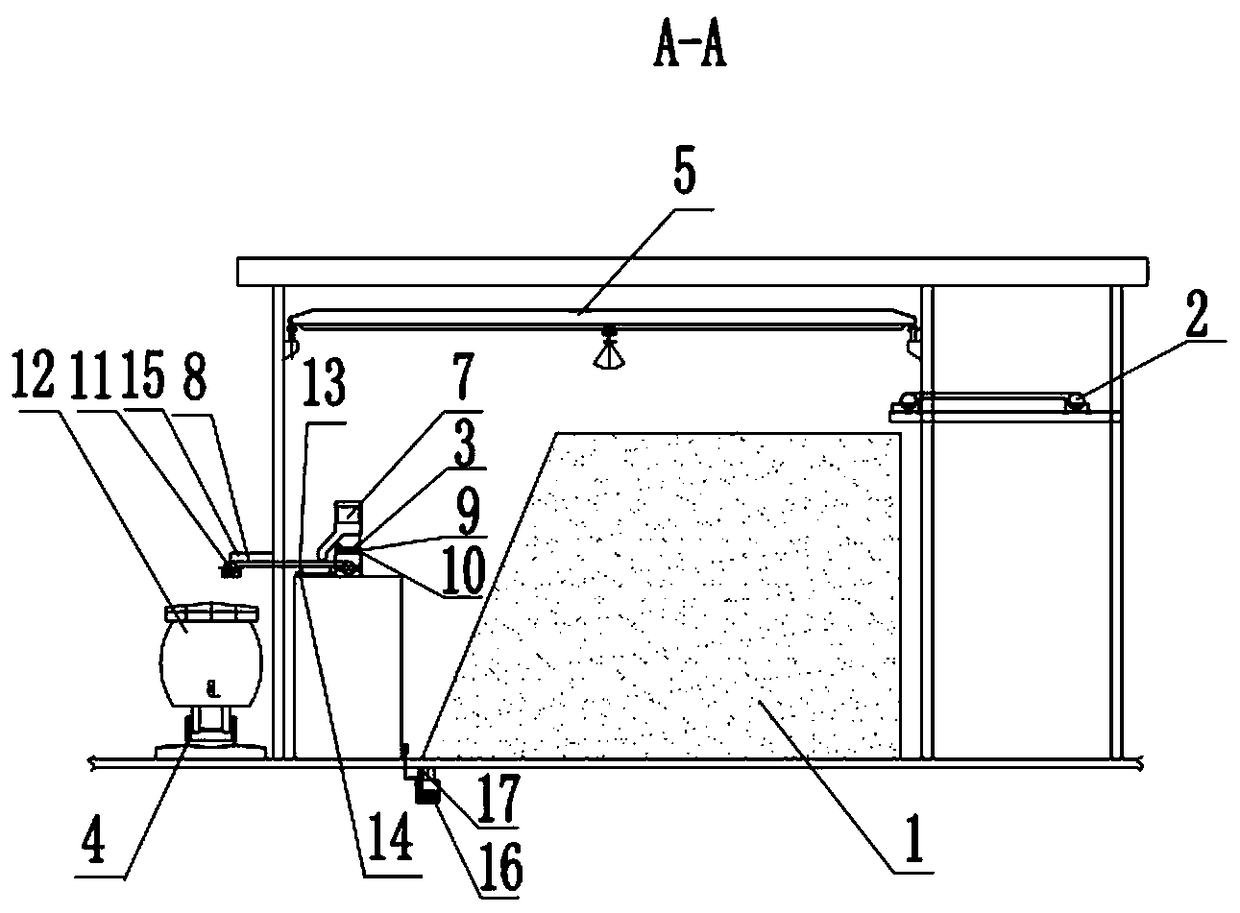

[0021] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] like figure 1 , 2 As shown, the iron concentrate storage and transportation system of the present invention is characterized in that it includes a roof arranged above the ore heap 1, a railway track 4 arranged on the side of the ore heap 1, and a group of mutually connected series on the railway track 4 A train carriage 12, a group of belt conveyors 2 arranged equidistantly along the length direction of the mine pile 1, an elevated belt that is arranged on one side of the mine pile 1 and parallel to the length direction of the mine pile 1 Conveyor 3, the concentrate lifting system arranged above the ore pile 1, the concentrate loading system arranged beside the ore pile, the iron concentrate in the filtering operation passes along the length direction of the ore pile 1, etc. The belt conveyor 2 arranged from the distance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com