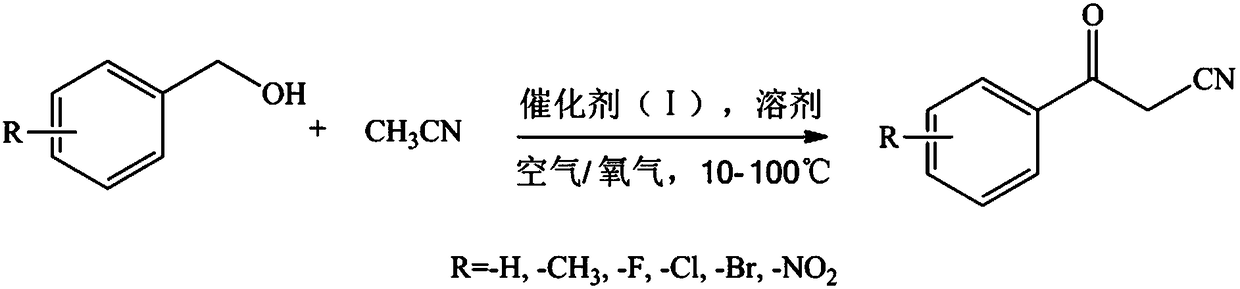

Method for preparing ketone nitrile by using metalloporphyrin polymer for catalytic coupling of aromatic alcohol and acetonitrile

A metalloporphyrin, aromatic alcohol technology, applied in the direction of organic compound/hydride/coordination complex catalyst, organic compound preparation, physical/chemical process catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

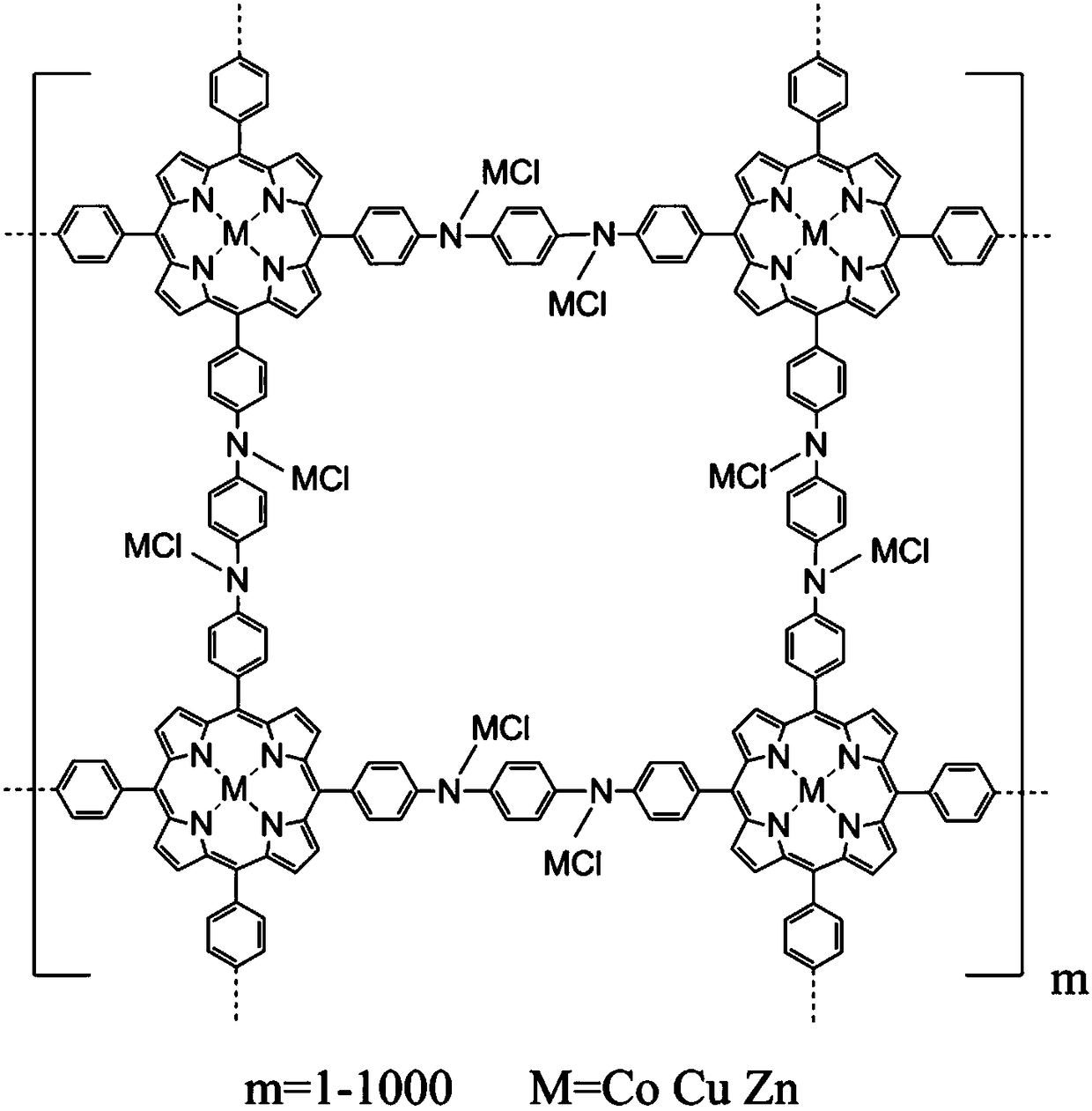

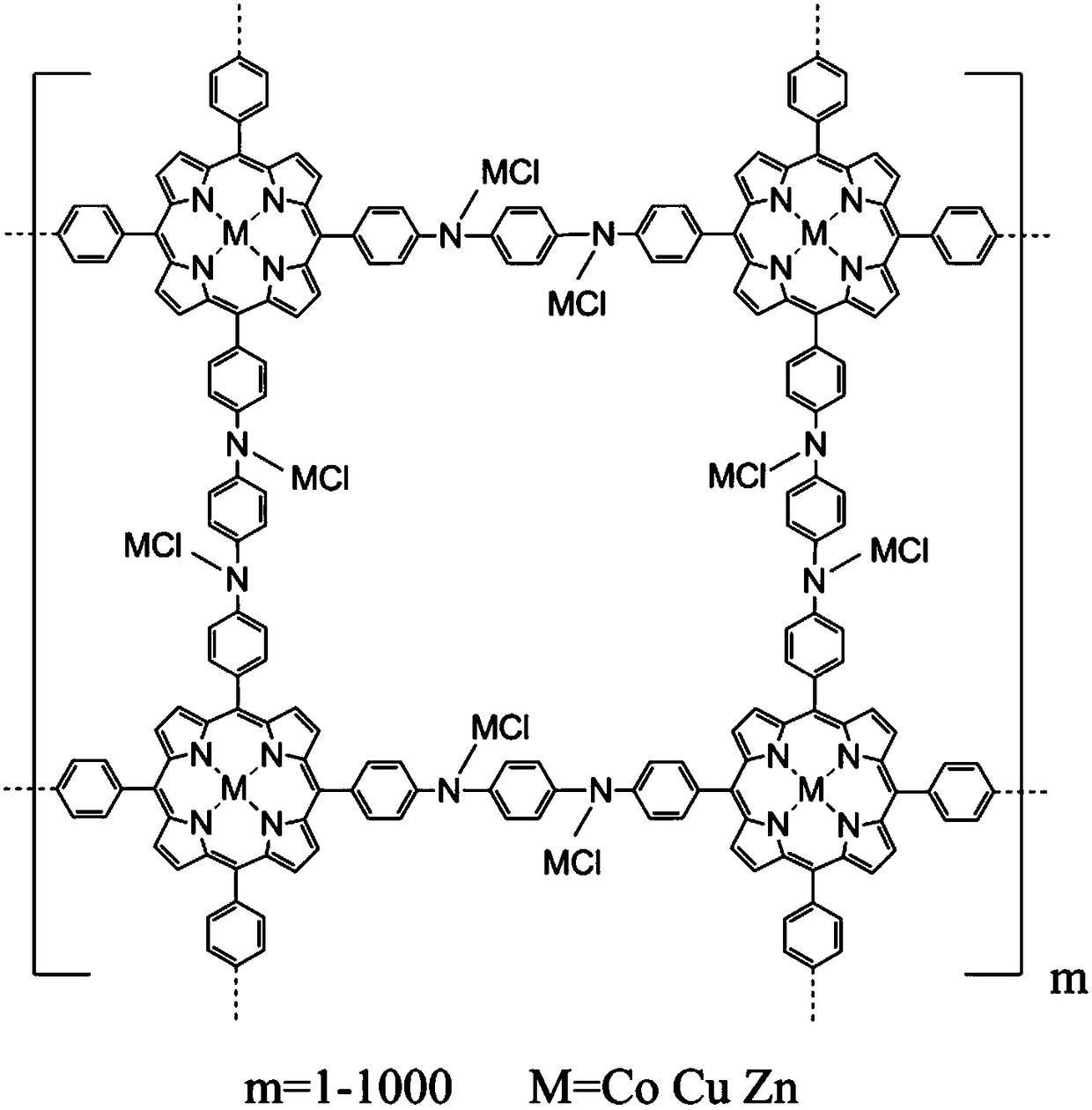

Embodiment 1

[0012] 10mg of the metalloporphyrin polymer with the structure of structural formula (I), M=Cu(II), m=382, specific surface area 730m 2 / g. Benzyl alcohol (1mmol, 0.108g), acetonitrile (5mmol, 0.206g), KOH (3mmol, 0.168g) were added to 10mL of N,N-dimethylformamide, and 50mL / min of air was blown. The reaction was stirred at 60°C for 5 hours, the corresponding yield of ketone nitrile was 93%, and the conversion of benzyl alcohol was 92%.

Embodiment 2

[0014] 10mg of the metalloporphyrin polymer with the structure of structural formula (I), M=Zn(II), m=510, specific surface area 680m 2 / g. P-Nitrobenzyl alcohol (1mmol, 0.153g), acetonitrile (10mmol, 0.411g), KOH (3mmol, 0.168g) were added to 10mL of dimethyl sulfoxide, and 50mL / min of air was introduced. The reaction was stirred at 80°C for 3 hours. The yield of the corresponding ketonitrile was 90% and the conversion rate of p-nitrobenzyl alcohol was 91%.

Embodiment 3

[0016] 10mg of the metalloporphyrin polymer with the structure of structural formula (I), M=Co(II), m=280, specific surface area 850m 2 / g. P-methylbenzyl alcohol (1mmol, 0.122g), acetonitrile (10mmol, 0.411g), t-BuOK (3mmol, 0.336g), added to 10mL of 1,3-dimethyl-2-imidazolinone, through Into 50mL / min air. The reaction was stirred at 50°C for 8 hours, the corresponding ketonitrile yield was 91%, and the p-methylbenzyl alcohol conversion rate was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com