Synthetic method and equipment for aqueous polymer emulsion

A technology of water-based polymers and synthesis methods, applied in the direction of coating, etc., can solve problems such as uneven reaction and uneven heating, and achieve the effects of overcoming uneven heating, excellent performance, and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

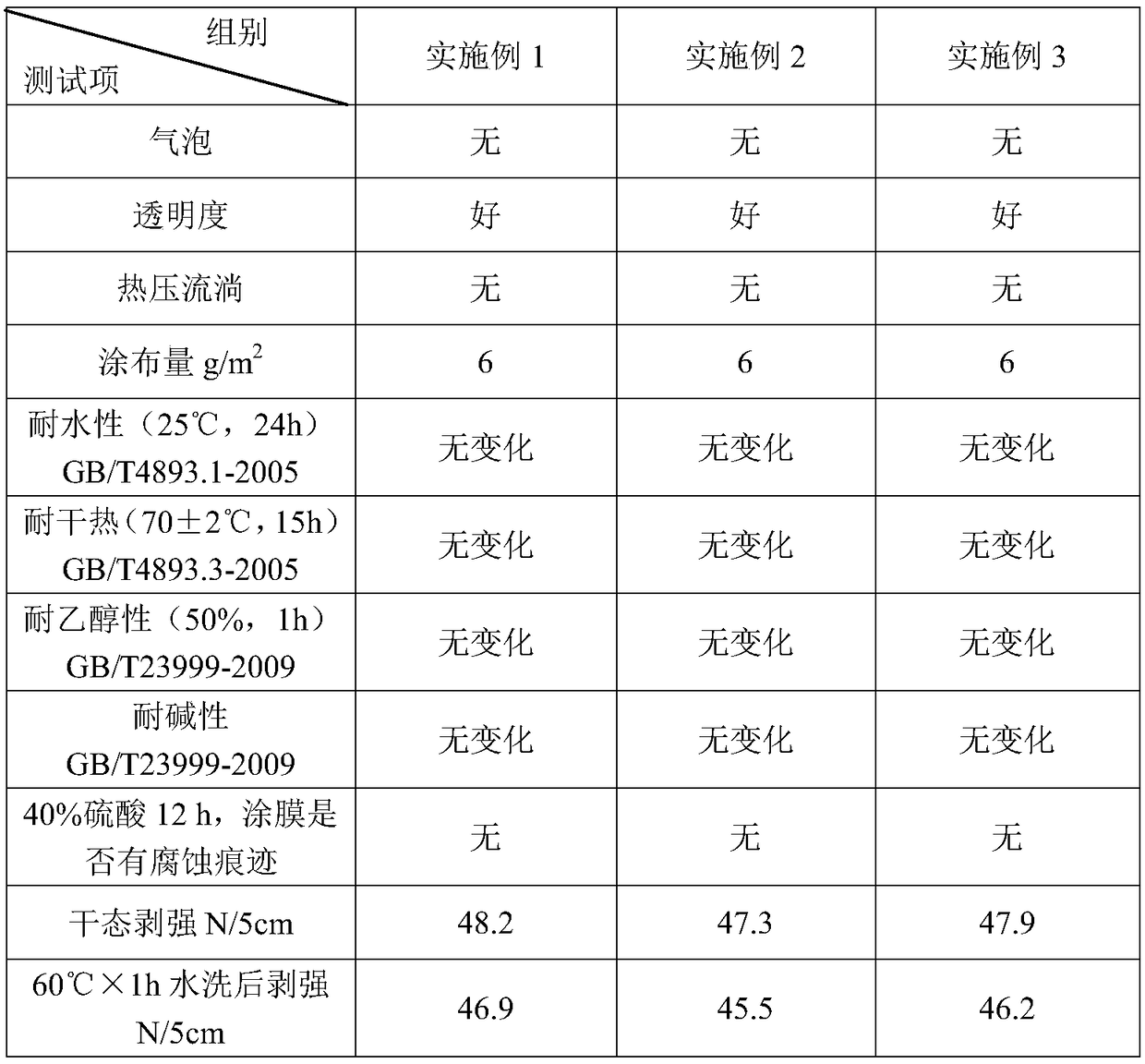

Embodiment 1

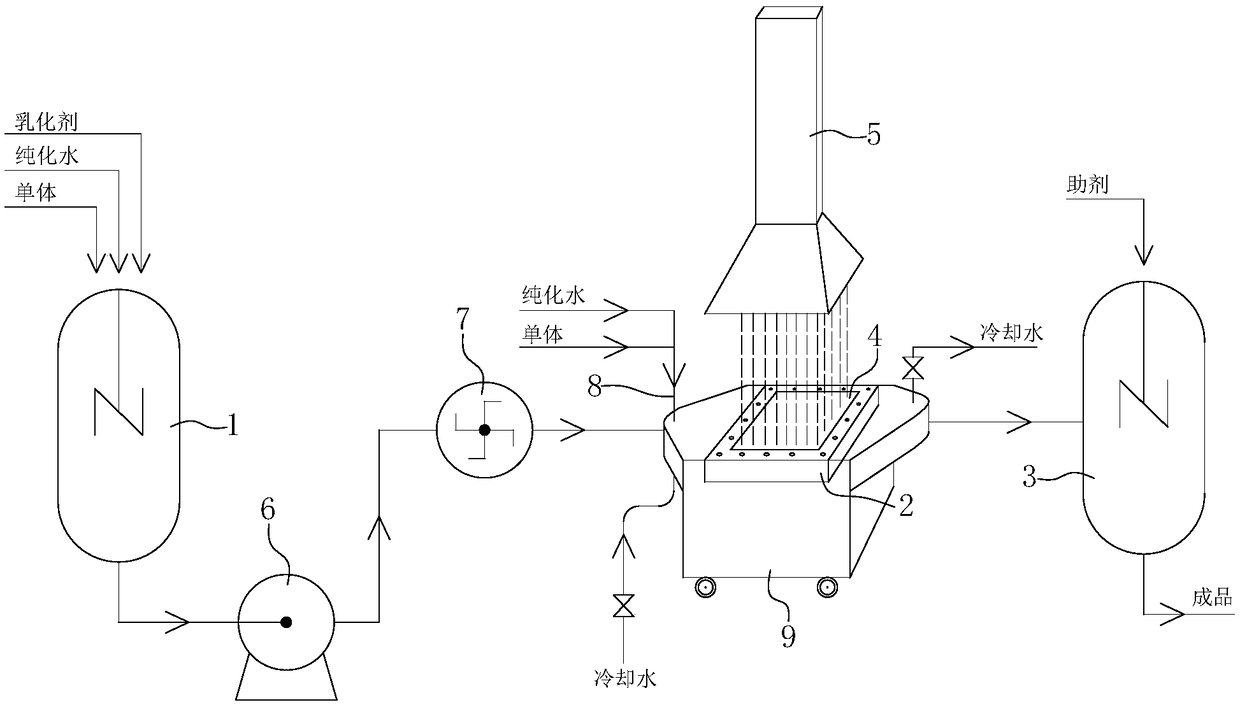

[0025] The synthetic method of aqueous polymer emulsion, comprises the following steps:

[0026] (1) Mix butyl acrylate, styrene, acrylic acid, N-methylol acrylamide, pure water, sodium lauryl sulfate and acetin together, and stir for 50 minutes at a speed of 2900r / min to obtain an emulsion;

[0027] The weight parts of each raw material are: butyl acrylate 30, styrene 15, acrylic acid 0.8, N-methylol acrylamide 0.7, pure water 60, sodium lauryl sulfate 0.075, Pingpingjia 3;

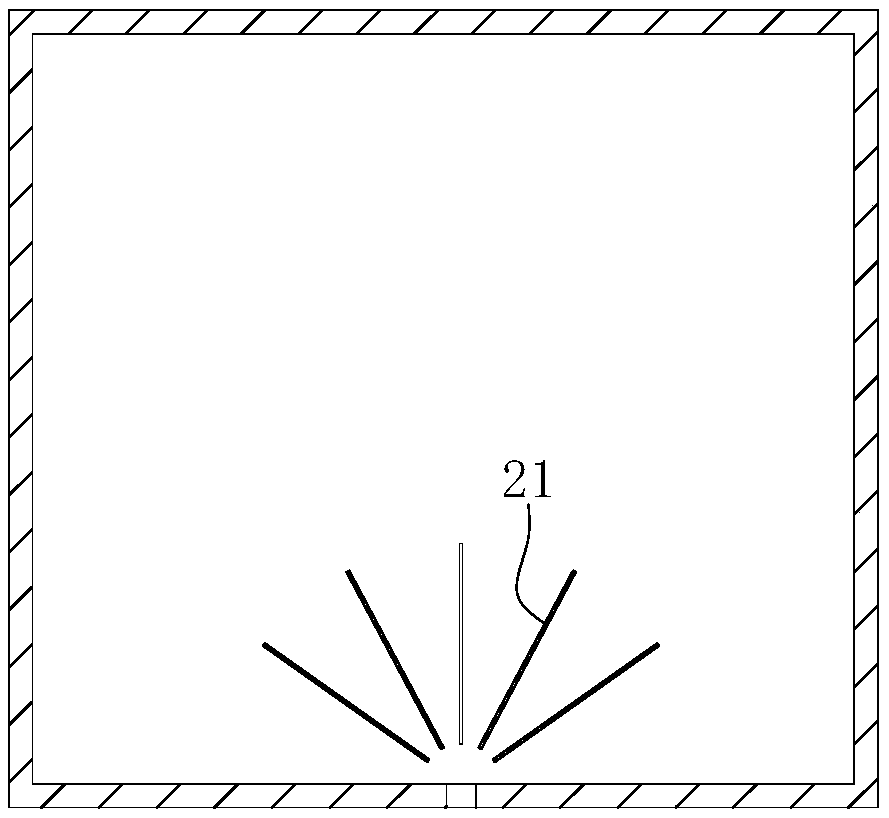

[0028] (2) A flat flow reaction chamber is provided, and a titanium window and an electron accelerator are arranged above the flow reaction chamber. The electron beam generated by the electron accelerator can pass through the titanium window and enter the flow reaction chamber, and the emulsion is continuously flowed at a flow rate of 40,000 L / H. Add the mixture of acrylic acid and pure water to the flow reaction chamber continuously, wherein the addition of acrylic acid is 0.2% of the flow rate of the e...

Embodiment 2

[0030] The synthetic method of aqueous polymer emulsion, comprises the following steps:

[0031] (1) Mix butyl acrylate, styrene, acrylic acid, N-methylol acrylamide, pure water, sodium lauryl sulfate and acetaminophen, and stir at a speed of 2900r / min for 40min to obtain an emulsion;

[0032] The weight parts of each raw material are: butyl acrylate 20, styrene 10, acrylic acid 0.5, N-methylol acrylamide 0.5, pure water 50, sodium lauryl sulfate 0.05, Pingpingjia 2;

[0033] (2) A flat flow reaction chamber is provided, and a titanium window and an electron accelerator are arranged above the flow reaction chamber. The electron beam generated by the electron accelerator can pass through the titanium window and enter the flow reaction chamber, and the emulsion is continuously flowed at a flow rate of 30,000 L / H. Add the mixture of acrylic acid and pure water to the flow reaction chamber continuously, wherein the addition of acrylic acid is 0.2% of the flow rate of the emulsion,...

Embodiment 3

[0035] The synthetic method of aqueous polymer emulsion, comprises the following steps:

[0036] (1) Mix butyl acrylate, styrene, acrylic acid, N-methylol acrylamide, pure water, sodium lauryl sulfate and acetin together, and stir for 60 minutes at a speed of 2900r / min to obtain an emulsion;

[0037] The weight parts of each raw material are: butyl acrylate 40, styrene 20, acrylic acid 1, N-methylol acrylamide 1, pure water 70, sodium lauryl sulfate 0.1, Pingpingjia 4;

[0038] (2) A flat flow reaction chamber is provided, and a titanium window and an electron accelerator are arranged above the flow reaction chamber. The electron beam generated by the electron accelerator can pass through the titanium window and enter the flow reaction chamber, and the emulsion is continuously flowed at a flow rate of 50,000 L / H. Add the mixture of acrylic acid and pure water to the flow reaction chamber continuously, wherein the addition of acrylic acid is 0.2% of the flow rate of the emulsio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap