Prefabricated GFRP pipe concrete pile and reinforced concrete slab top-mounted subgrade pile-slab structure

A technology of reinforced concrete slabs and concrete piles, applied in the field of foundation engineering, can solve the problems of overall or local settlement of roadbed, high maintenance costs, long construction period, etc., and achieve the effects of high stiffness, high bearing capacity, and small uneven settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

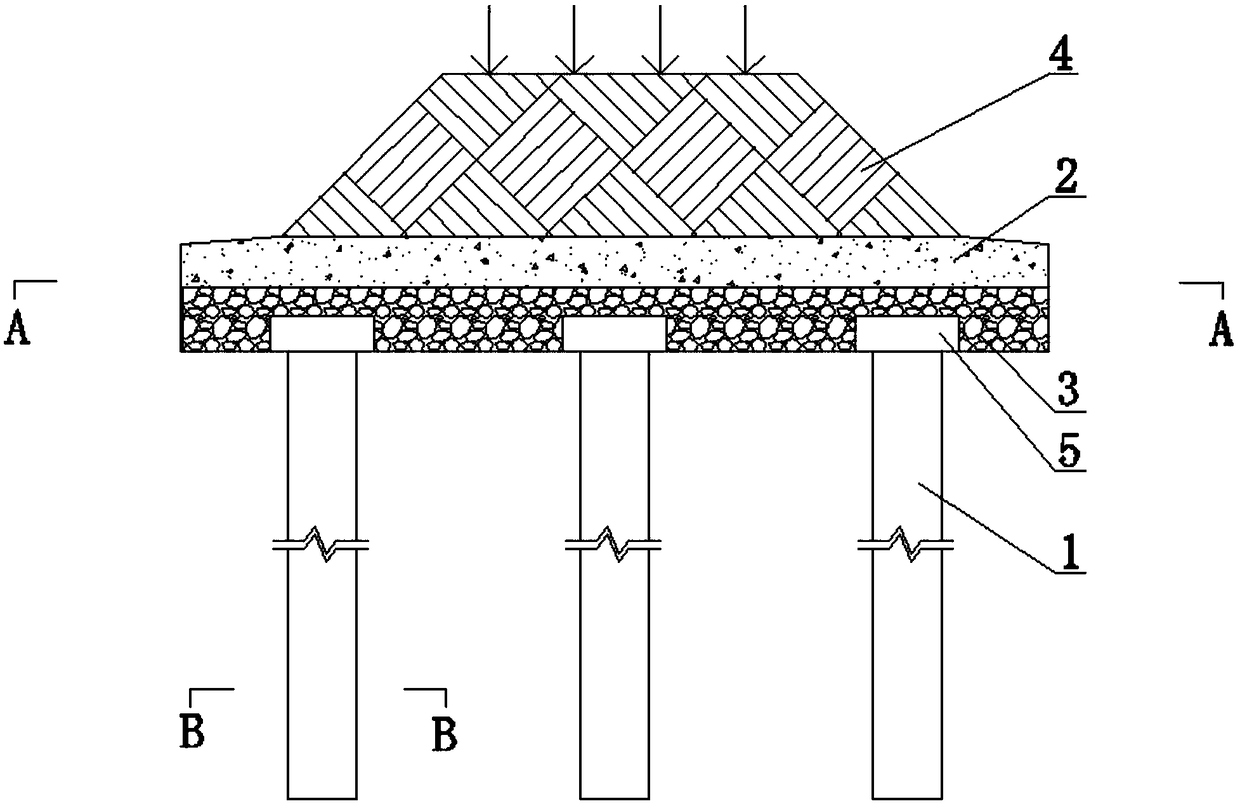

[0025] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 11 As shown, the present invention provides a prefabricated GFRP tubular concrete pile and a reinforced concrete slab top-mounted subgrade pile slab structure, including a GFRP tubular concrete pile 1, a reinforced concrete slab 2, a crushed stone cushion 3 and an embankment fill layer 4, crushed stone The cushion layer 3 is arranged under the reinforced concrete slab 2, the top of the GFRP pipe concrete pile 1 is connected to the bottom of the crushed stone cushion layer 3, the bottom of the crushed stone cushion layer 3 is in contact with the ground, and the embankment filling layer 4 is arranged on Above the reinforced concrete slab 2.

[0026] Specifically, the GFRP tube concrete pile 1 includes a first GFRP tube 9 and concrete 6, the first GFRP tube 9 is filled with concrete 6, and the first GFRP tube 9 is used to wrap the concrete 6, on the one hand, the GFRP tube concr...

Embodiment 2

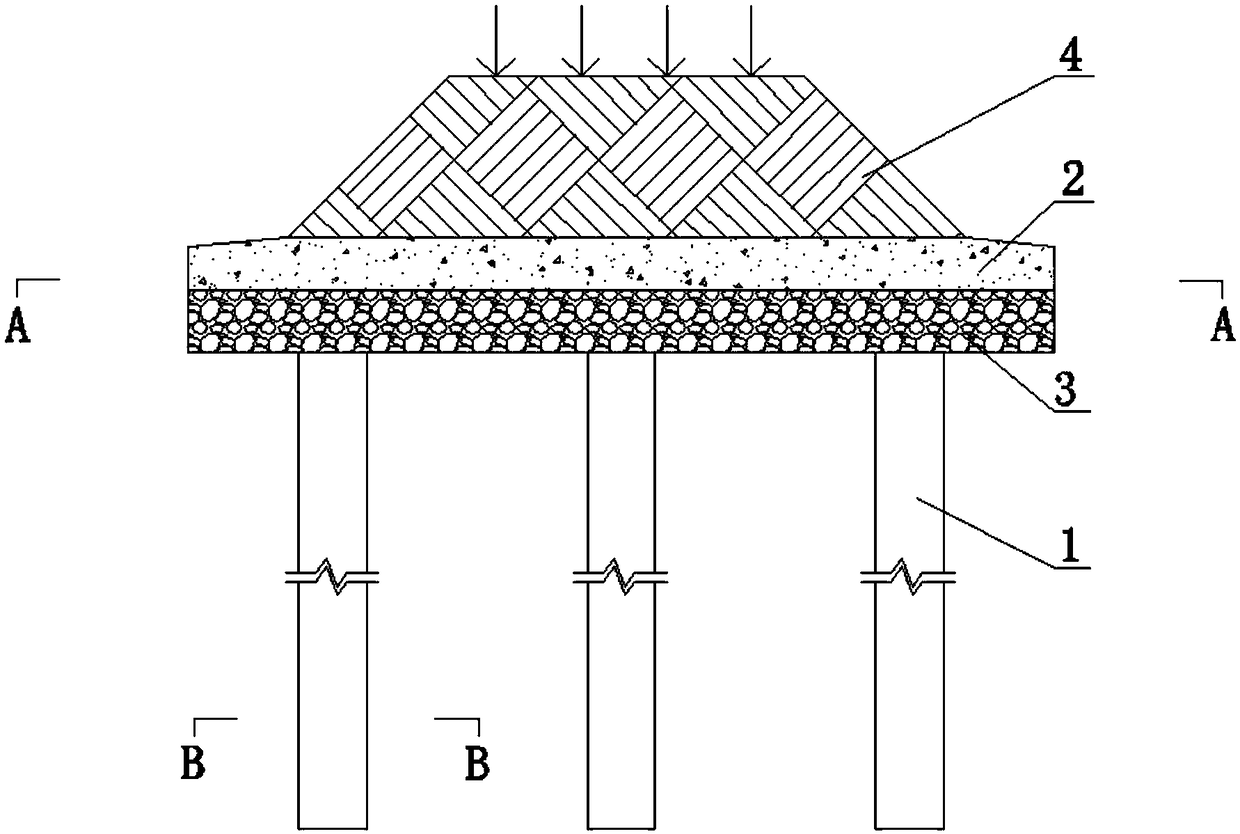

[0039] Prefabricated GFRP pipe concrete piles and reinforced concrete slab top-mounted subgrade pile-slab structure, other features are the same as in embodiment 1, the difference is that another kind of subgrade pile-slab structure without pile cap 5 is disclosed in this embodiment, such as figure 2 As shown, the top of the GFRP tubular concrete pile 1 is connected to the bottom of the crushed stone cushion layer 3, and there is no pile cap 5 design, the pile body of the GFRP tubular concrete pile 1 is pierced with the crushed stone cushion layer 3, and the soil between the piles is compressed and dense To bear part of the upper load, reduce the load on the pile body, thereby saving pile body materials, and is suitable for foundations with relatively good soil quality.

Embodiment 3

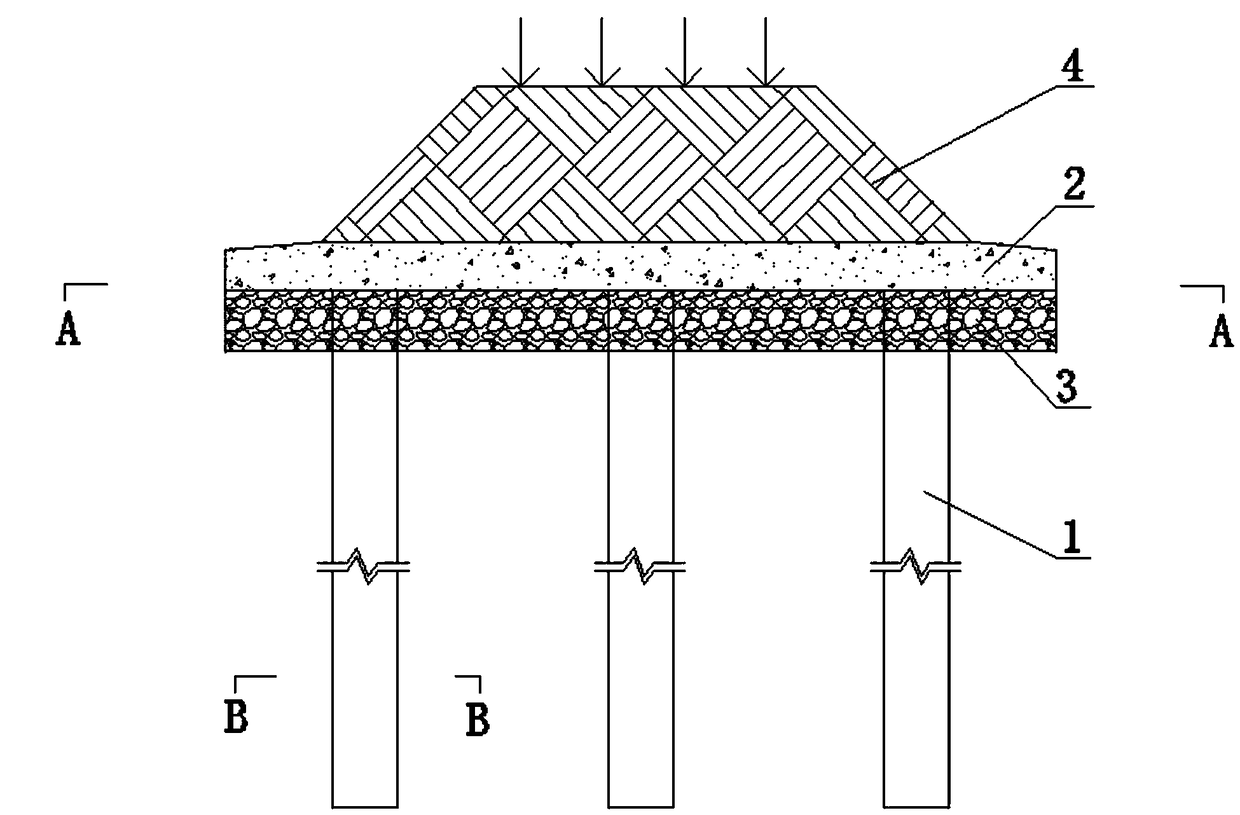

[0041] Prefabricated GFRP tubular concrete pile and reinforced concrete slab top-mounted subgrade pile-slab structure, other features are the same as in embodiment 1, the difference is that the top of another GFRP tubular concrete pile 1 is disclosed in this embodiment. The structure of the stone mattress cushion 3, such as image 3 As shown, the top of the pile body of the GFRP tubular concrete pile 1 penetrates the crushed stone cushion layer 3 and is connected to the bottom of the reinforced concrete slab 2. The settlement generated by the compression of the cushion between the plates 2 improves the stability of the foundation. For soft ground with poor soil quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com